Method for producing artificial fishing bank

A production method and fish reef technology, applied in the field of artificial fish reef production, can solve the problems of difficulty in obtaining materials and high manufacturing costs, and achieve the effects of simple process, easy access to raw materials, good fish collection effect and aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

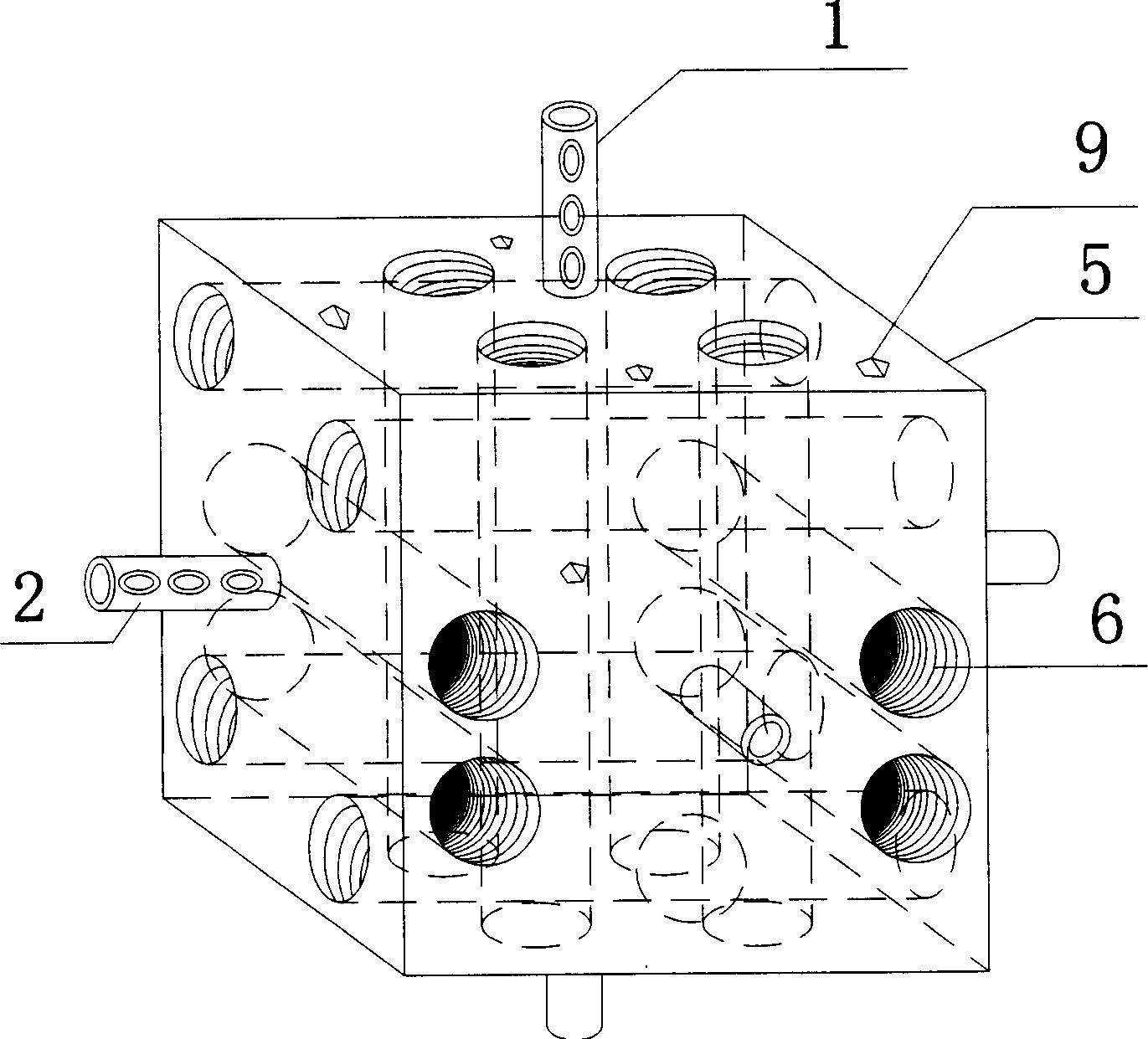

[0015] Example 1: First, a certain amount of steel bars are used to bind a cube-shaped skeleton 5 . The volume is 1 cubic meter. Fill fine sand inside the columnar polyethylene hose mold 6, and put it into the fish reef skeleton 1 horizontally. Then use cement, sand, and stone to mix into concrete at a mixing ratio of 3:2:3, and fill it into the fish reef skeleton with polyethylene hoses, and at the same time place it on the 6 sides of the cube. Connect member 1 or 2. When arranging the connecting member, at least one of the cube faces needs to place the connecting member 1 or 2. When the concrete is solidified, the fine sand in the polyethylene hose mold can be poured out, and the polyethylene hose mold can be pulled out from the reef at the same time. When the fish reef skeleton concrete is about to solidify, add a certain amount of stones 9 on its surface, allow the stones to be fixed on the fish reef surface to form a protrusion, or wash the fish reef surface with water...

example 2

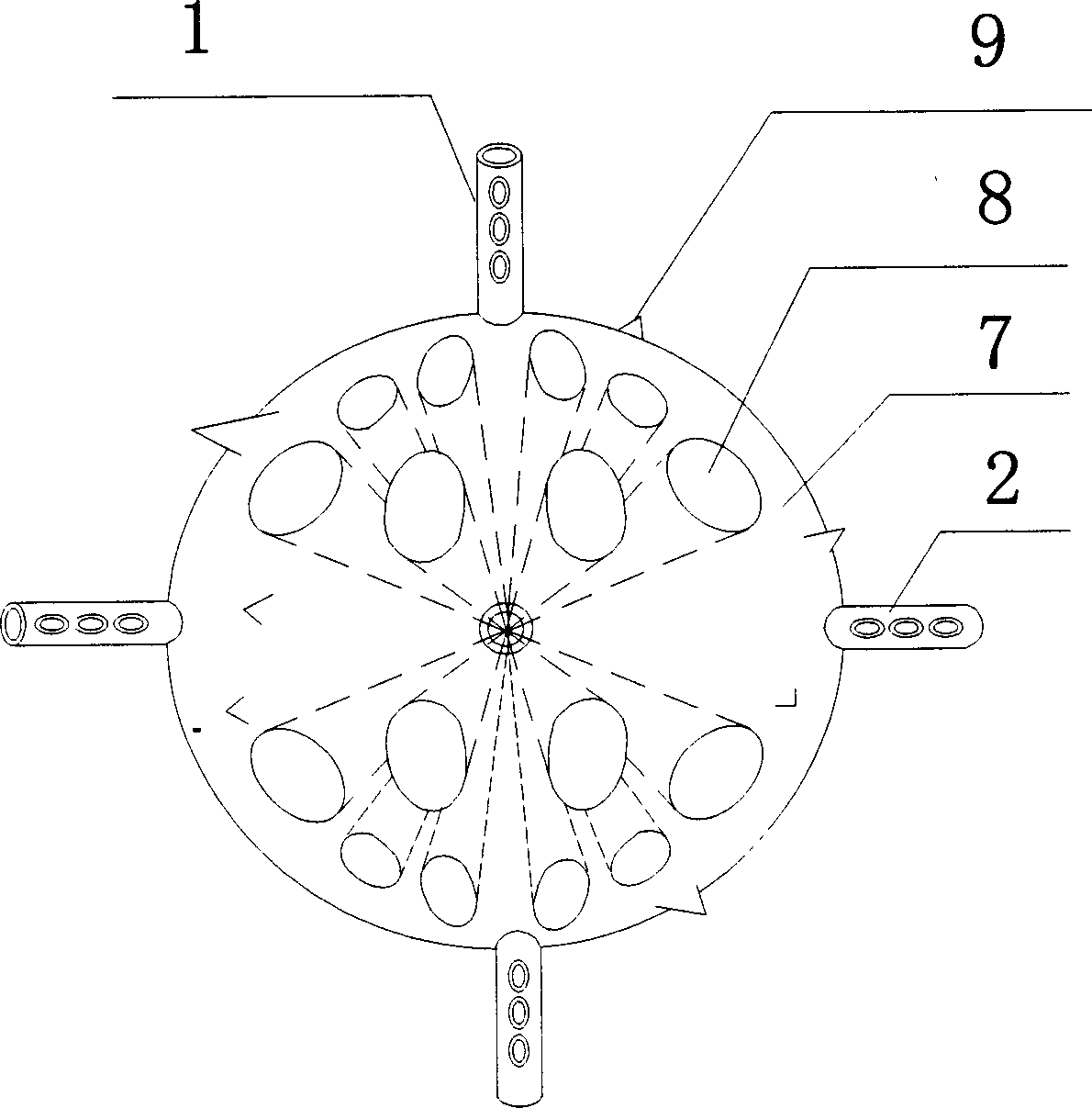

[0016] Example 2: First, bind a certain amount of steel bars into a spherical skeleton 7 . The volume is 1 cubic meter. Be full of soil in conical polyethylene hose mold 8 inside, and it is inserted in the fish reef skeleton 7 towards the spherical center. Then use cement, sand and stone to mix into concrete at a mixing ratio of 5:4:4. And fill it into the fish reef skeleton that the polyethylene hose is placed on, and at the same time insert the connecting member 1 or 2 respectively on the spheroid. When placing the connecting member, at least one point on the spherical surface needs to install the connecting member 1 or 2. When the concrete is solidified, the soil in the polyethylene hose mold can be poured out, and the polyethylene hose mold can be pulled out from the reef at the same time. When the fish reef skeleton concrete is about to solidify, add a certain amount of self-stones 9 on its surface, let the stones be fixed on the fish reef surface to form a protrusion,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com