Method for reducing prop force with ring-shape mud sheath in pipe-jacking construction

A ring-shaped technology during construction, applied in the direction of pipeline laying and maintenance, pipes/pipe joints/fittings, mechanical equipment, etc., can solve the problem that the drag reduction effect is not very ideal, cannot be evenly distributed, and cannot form a stable and effective mud sheath and other problems, to achieve the effect of reducing the jacking force and reducing the frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

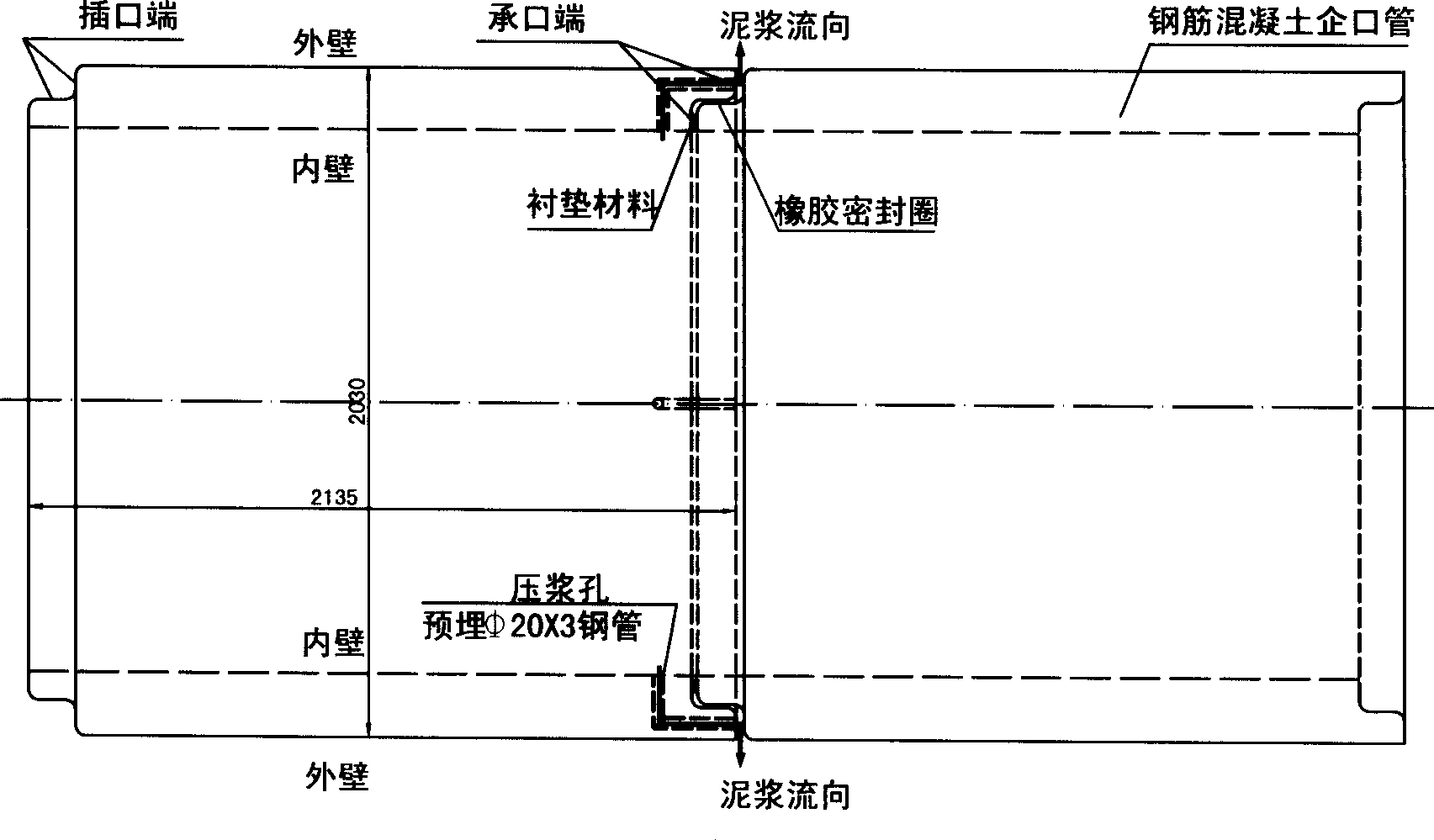

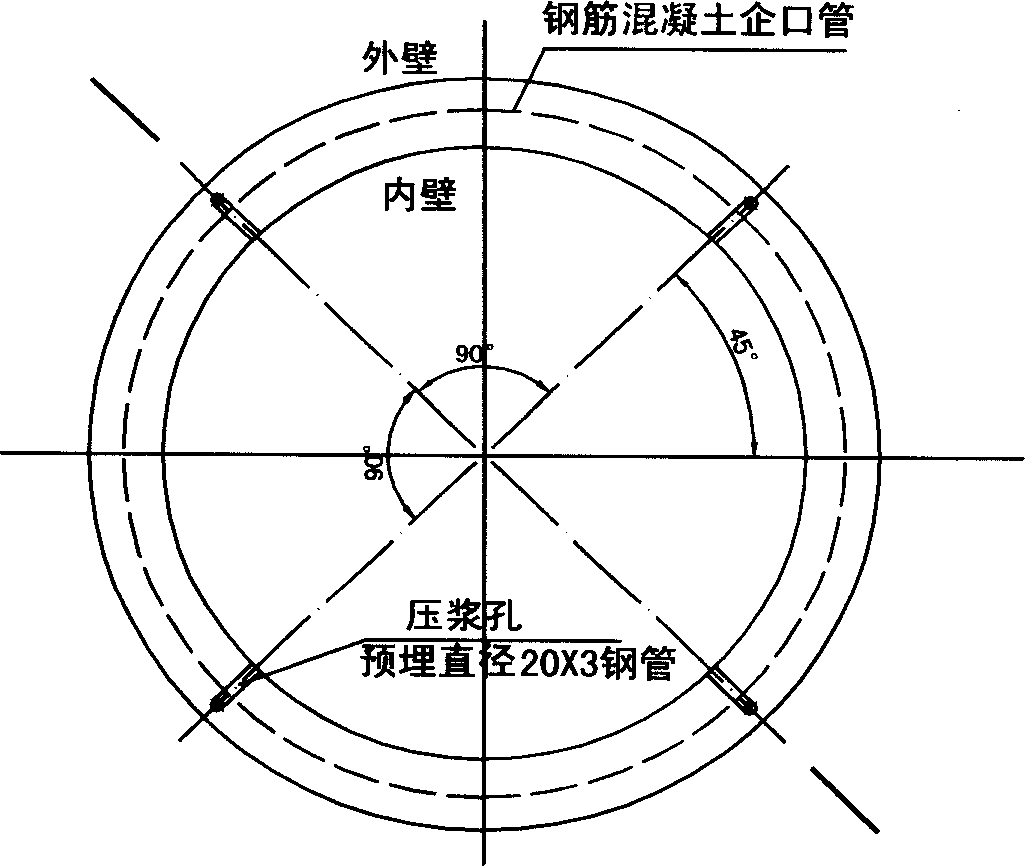

[0016] like figure 1 , figure 2 As shown, the project example is the sewage pipe jacking project in the combined sewage treatment project in Shanghai. The project adopts Φ1650mm reinforced concrete grooved pipe, outer diameter Φ2030mm, wall thickness 190mm, the effective length of each section is 2000mm, and the total length is 2135mm. The project section is from Well No. 12 at the intersection of Langao Intersection of Zhongshan North Road to Dongxin Intersection of Guangfu West Road, with a total length of 231.5m and divided into two jackings.

[0017] The first jacking pass is constructed using the traditional point grouting method; the second jacking pass is constructed using the annular grouting method of the present invention.

[0018] In the first jacking journey, due to the point-like grouting method, the grouting work is not ideal, and the jacking force rises rapidly during the jacking. After 22 knots of jacking, when the jacking length is 45m, the grouting measure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com