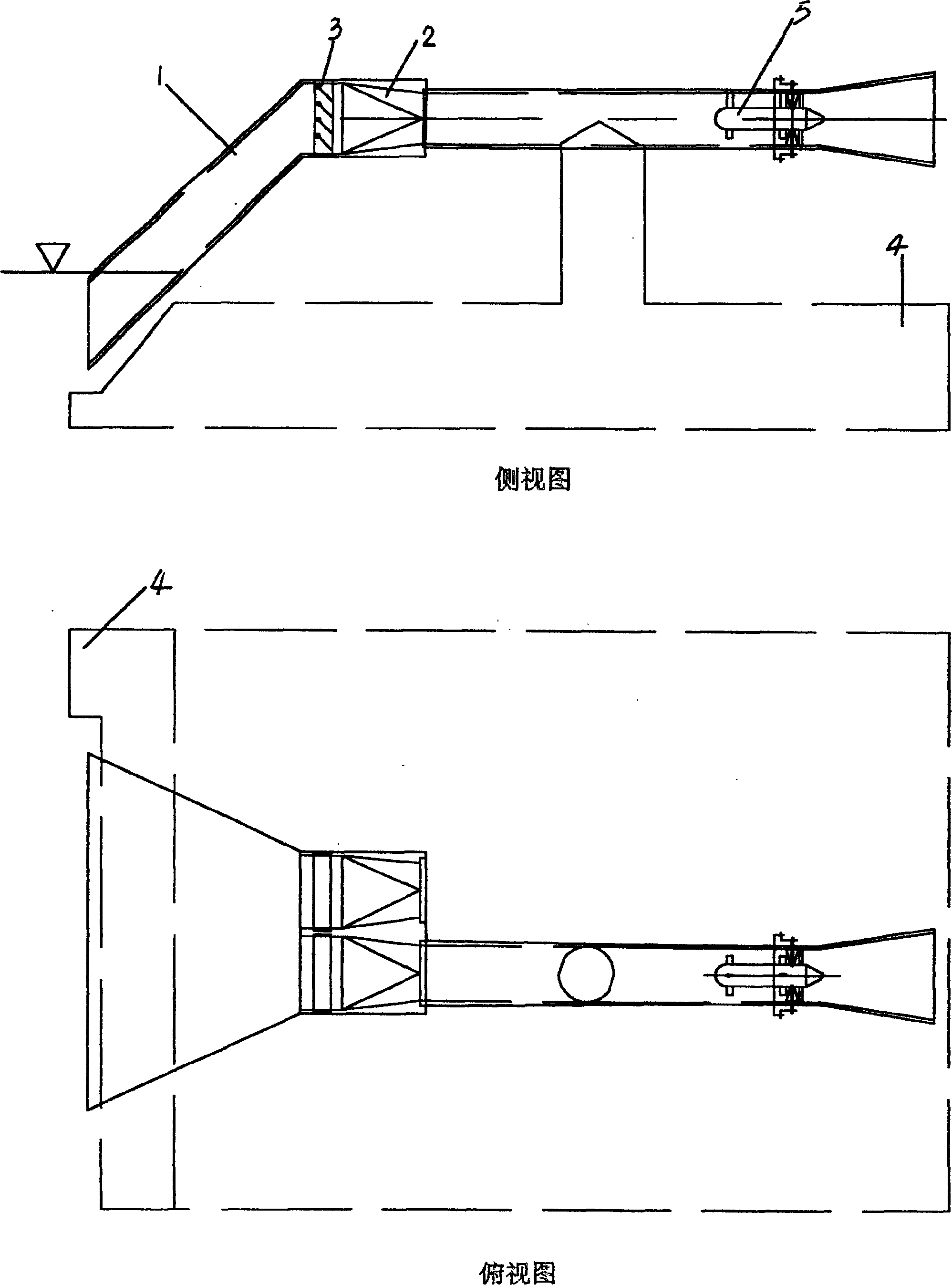

Air chamber oblique laying in shore type one-directional stable airflow wave energy electric power generating apparatus

An air chamber and wave energy technology, applied in ocean energy power generation, engine components, machines/engines, etc., can solve the problems of low efficiency, small power generation capacity, floating by water or being able to be hoisted, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] Here is a way to build a large combined wave power plant:

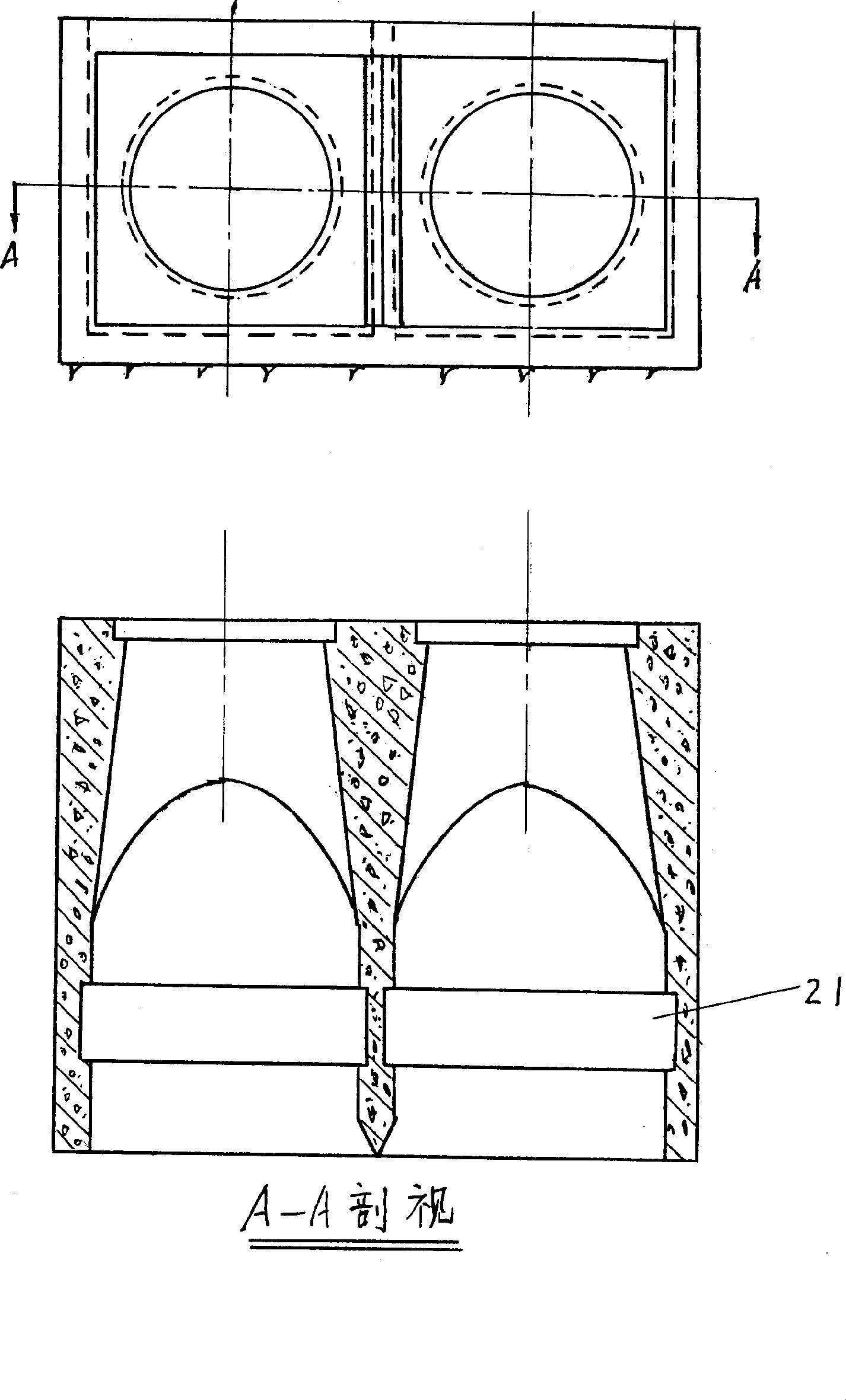

[0068] Build multiple oscillating air chambers next to each other on the seashore, connect the air outlet of the radius gradient section 2 with a larger-diameter pipe, and share a stabilizing air chamber and a turbine generator set for every two to four oscillating air chambers , of course at this time the capacity of the stabilizing air chamber will be larger than that of a single oscillating air chamber system. In this way, the number of the pressure-stabilizing air chamber and the turbine generator set can be reduced, and the single capacity of the device is increased. The compressed air of the whole power station is connected, and the number of units to be started can be selected according to the needs, and the operation is flexible and convenient. Ensure that the turbine unit works in the highest efficiency zone, which can also improve efficiency. In this way, a large-scale wave energy power plant can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com