Machining process of liquid pipe for gas-liquid separator

A technology of a gas-liquid separator and a processing method, which is applied in the field of welding processing, can solve problems such as solder penetration, and achieve the effects of improving welding quality, improving performance, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

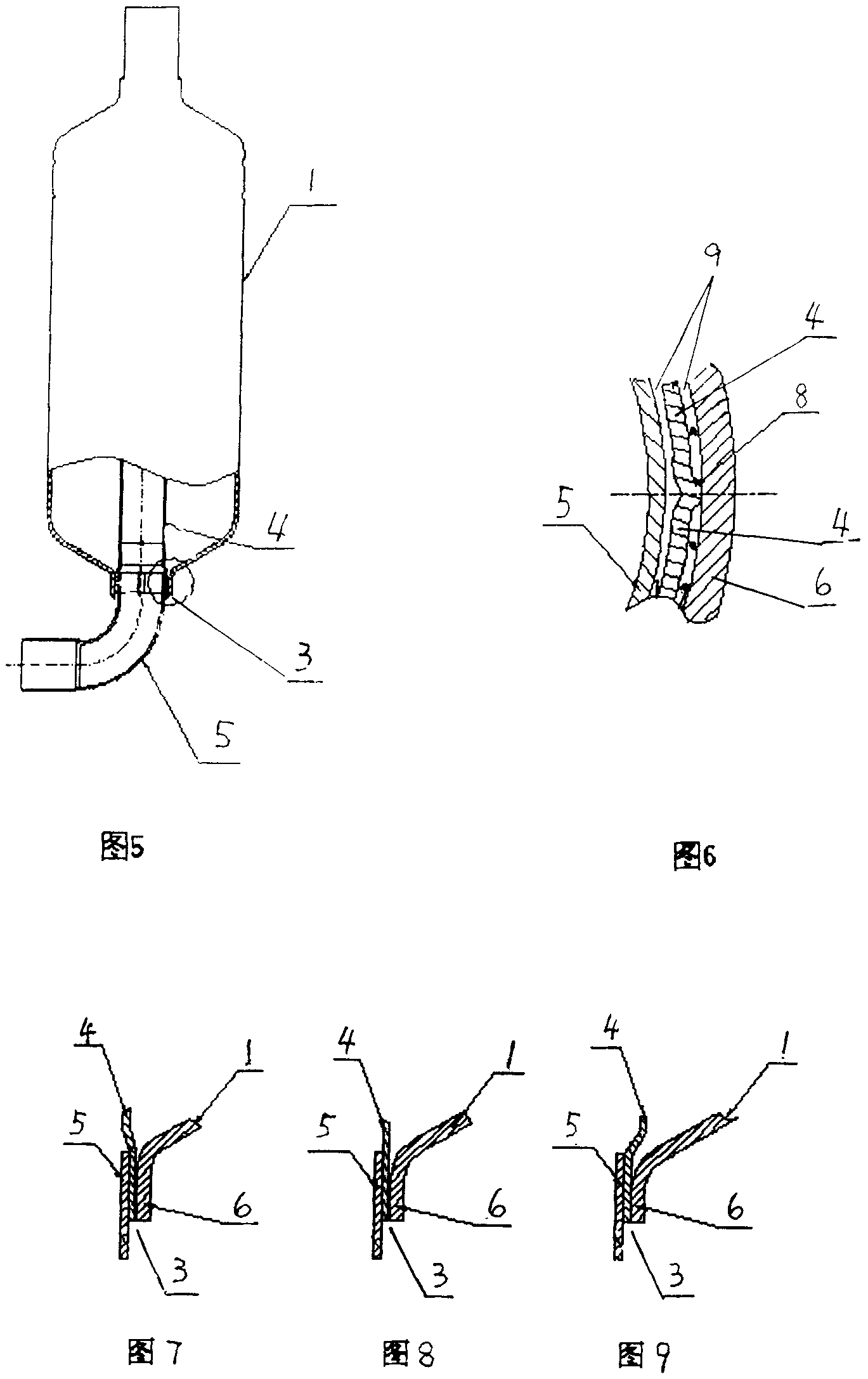

[0028] like Figure 5 As shown, the bottom of the reservoir body 1 is provided with a liquid outlet 3, which is enlarged as Figure 6-Figure 9 As shown, there is a vertical tubular flange 6 downward along the central axis on the liquid outlet 3, and the inner iron pipe 4 is flared (see Figure 7 ) or flanging (see Figure 9 ) or maintain the original straight tubular shape (see Figure 8 ), and then the inner iron pipe 4 is pressed into the tubular flange 6 of the reservoir body 1, and the inner iron pipe 4 is flared or straight or the outer side of the flange is provided with three or four convex ribs 8 (can be set according to the inner iron pipe 4. Increase the ribs 8 to 5-8 according to the size of the diameter), so that the inner diameter of the inner iron pipe 4 and the tubular flange 6 of the liquid reservoir body 1 produces an interference fit, and leaves a welding gap 9, and then the outer copper pipe 5 Put it into the flaring or straight pipe or flanging of the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com