Maching process and mold for annulus of external gear reduced one-way device

A technology of external ring gear and one-way device, which is applied in the direction of manufacturing tools, metal extrusion dies, and other manufacturing equipment/tools, can solve the problems of complex molds, high production costs, and low work efficiency, so as to improve production efficiency and production efficiency. The effect of low cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

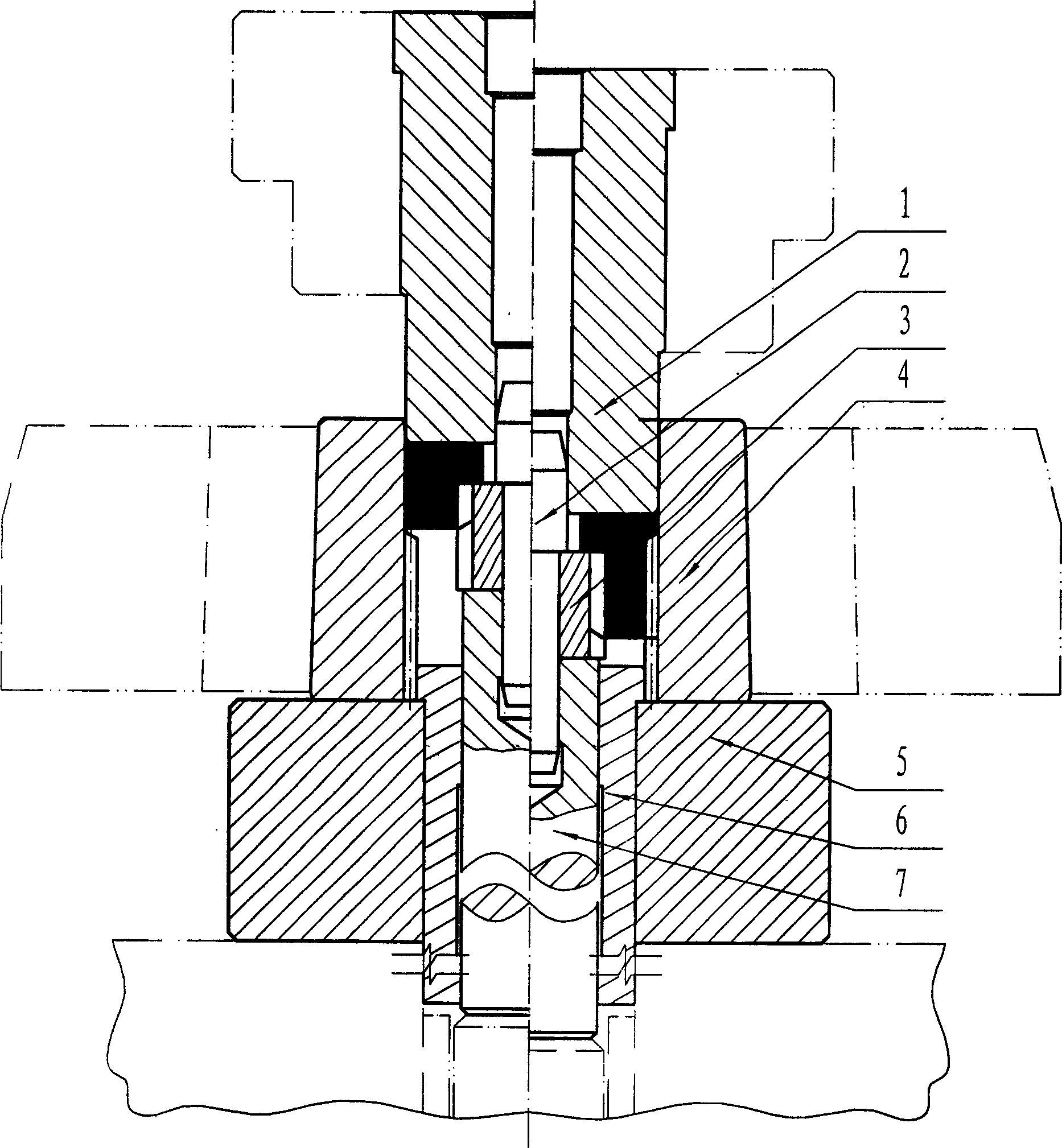

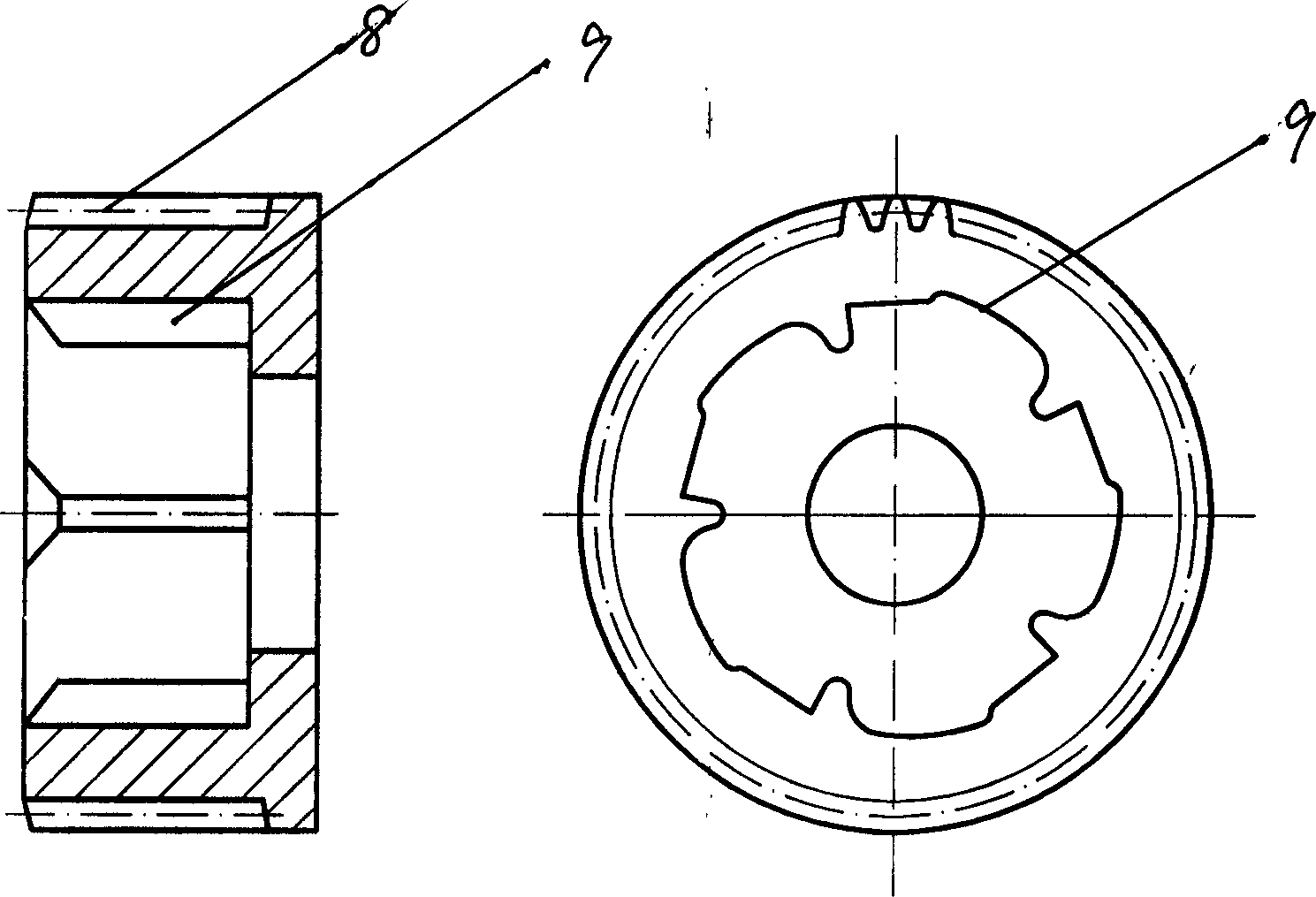

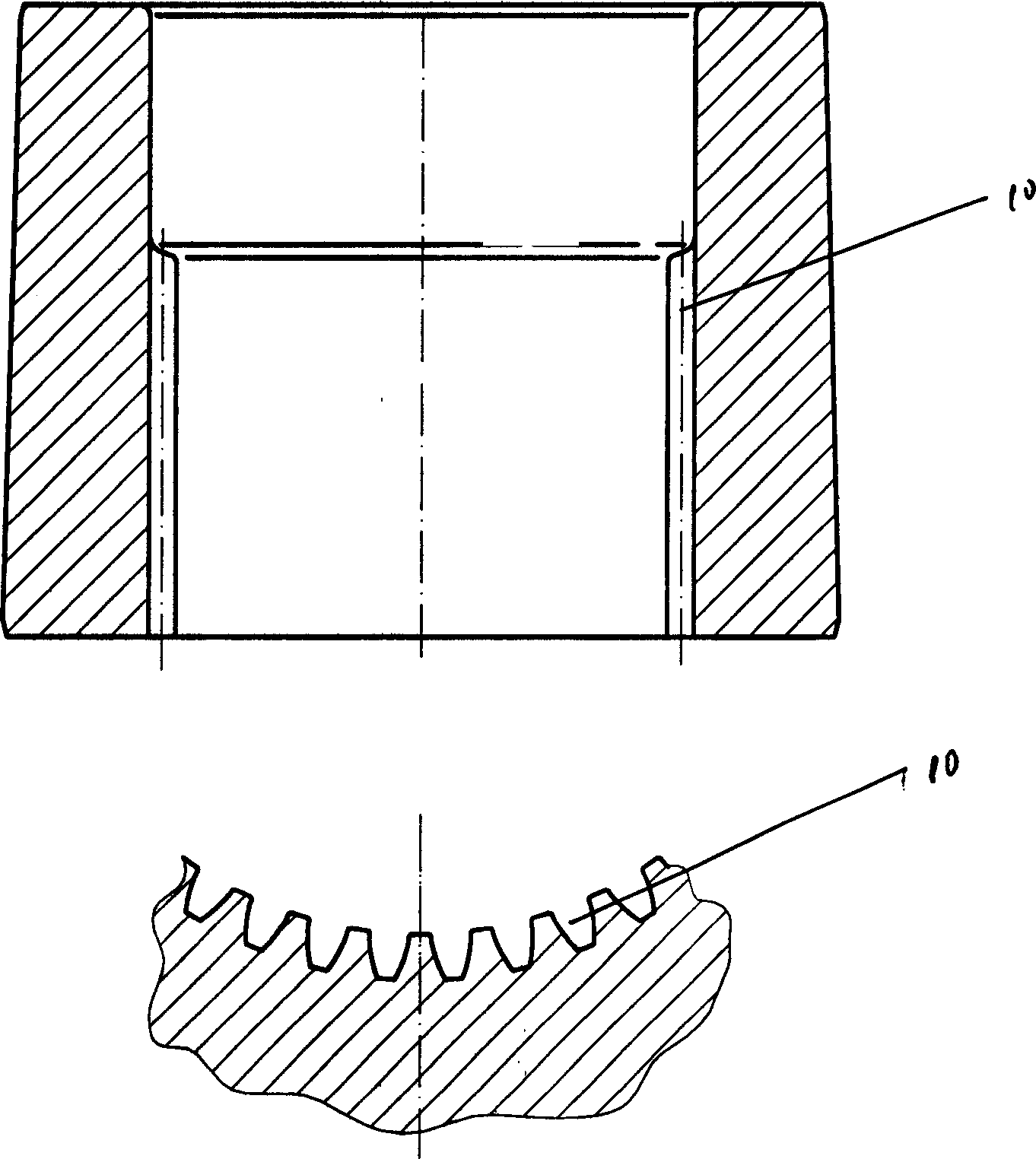

[0015] 1. First, process the raw material to be processed into rough bad material according to the shape requirements of the target part. According to the process requirements of cold die extrusion, anneal and soften the raw material to be processed so that its hardness is within the range of HB110-150, and then carry out Descaling, pickling, cleaning, and saponification in the saponification solution, and then through the cold die extrusion on the press to extrude the one-way outer ring gear with the star wheel blank and the star wheel internal teeth 9 Rough billet, then put the rough billet into the secondary forming mold, and press it for the second time to complete the forming of the external gear 8 of the outer ring gear, and complete the production of the outer ring gear of the one-way device after processing and heat treatment.

[0016] In order to realize the above-mentioned process, the present invention also provides a combined mold. This set of molds is composed of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com