Olefin/polar alpha-olefin copolymer and preparation method and uses

An olefin copolymer, a technology of the copolymer, which is applied to the application of the above-mentioned copolymer and the preparation field of the above-mentioned copolymer, can solve the problems of low molecular weight, inability to prepare a stereoregularity-functionalized polyolefin, etc., and achieves the improvement of compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

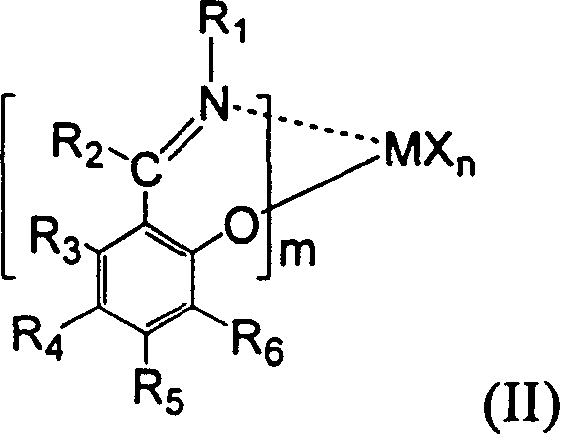

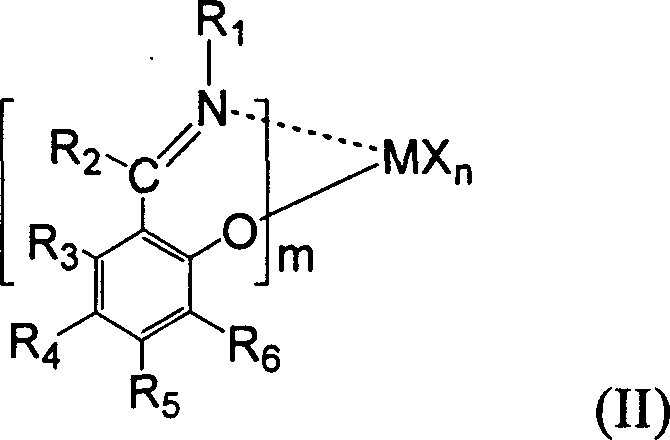

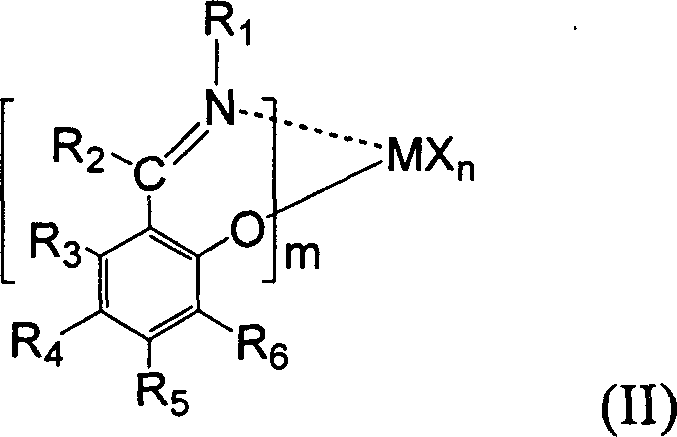

Method used

Image

Examples

Embodiment 1

[0214] Example 1: Ethylene / polar α-olefin copolymer

[0215]

[0216] Under the protection of nitrogen, add 100 mL of dry toluene to a 250 mL dry deoxygenated glass reactor equipped with mechanical stirring, and add 8.0 mmol triisobutyl aluminum Al( i Bu) 3 , 8.0mmol undecenol and 0.55mL methylaluminoxane (MAO, 1.4mol / L toluene solution, Al / Zr=770), feed ethylene gas with a pressure of 76mmHg, and place the reactor in a water bath at 25℃ In the polymerization reaction, adding 1.0×10 -6 mol catalyst (see the structure shown in formula (VIII) above). After 5 minutes of polymerization, 5 mL of hydrochloric acid was added to acidify the ethanol to terminate the polymerization reaction, and the polymerized product was washed and filtered with ethanol and dried in vacuum until constant weight. The obtained polymer 1.6g, 1 HNMR test contains 0.67 mol% of undecenol.

[0217] Others are the same as in Example 1. The operating conditions and characteristics of polyethylene / undecenol are l...

Embodiment 8

[0220] Example 8: Propylene / polar α-olefin copolymer

[0221] Other conditions are exactly the same as in Example 1. Propylene gas is used instead of ethylene gas, undecylenic acid is used instead of undecenol, Al(iBu) 3 The molar ratio to undecylenic acid=2, and the content of polar α-olefin in the obtained polymer is 0.10 mol%.

Embodiment 9

[0222] Example 9: 1,5-hexadiene / polar α-olefin copolymer

[0223] Under the protection of nitrogen, add 90 mL of dry toluene to a 250 mL dry deoxygenated glass reactor equipped with mechanical stirring, and add 8.0 mmol triisobutyl aluminum Al( i Bu) 3 , 8.0mmol undecenol and 0.55mL methylaluminoxane (MAO, 1.4mol / L toluene solution, Al / Zr=770), 10mL dry 1,5-hexadiene monomer, put the reactor in In the water bath at 25℃, the polymerization reaction is added 1.0×10 -6 Start after mol catalyst. After 24 hours of polymerization, 5 mL of hydrochloric acid was added to acidify the ethanol to terminate the polymerization reaction, and the polymerized product was washed and filtered with ethanol and dried in vacuum until constant weight. 1.2 g of the obtained polymer, 1 HNMR test contains 3.04 mol% of polar α-olefin.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com