Noise reducing apparatus of linear compressor

A linear compressor, noise technology, applied in mechanical equipment, machines/engines, liquid variable capacity machinery, etc., can solve the problem of ineffective reduction, affecting suction efficiency, inconsistency, etc., to reduce suction noise and improve suction. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

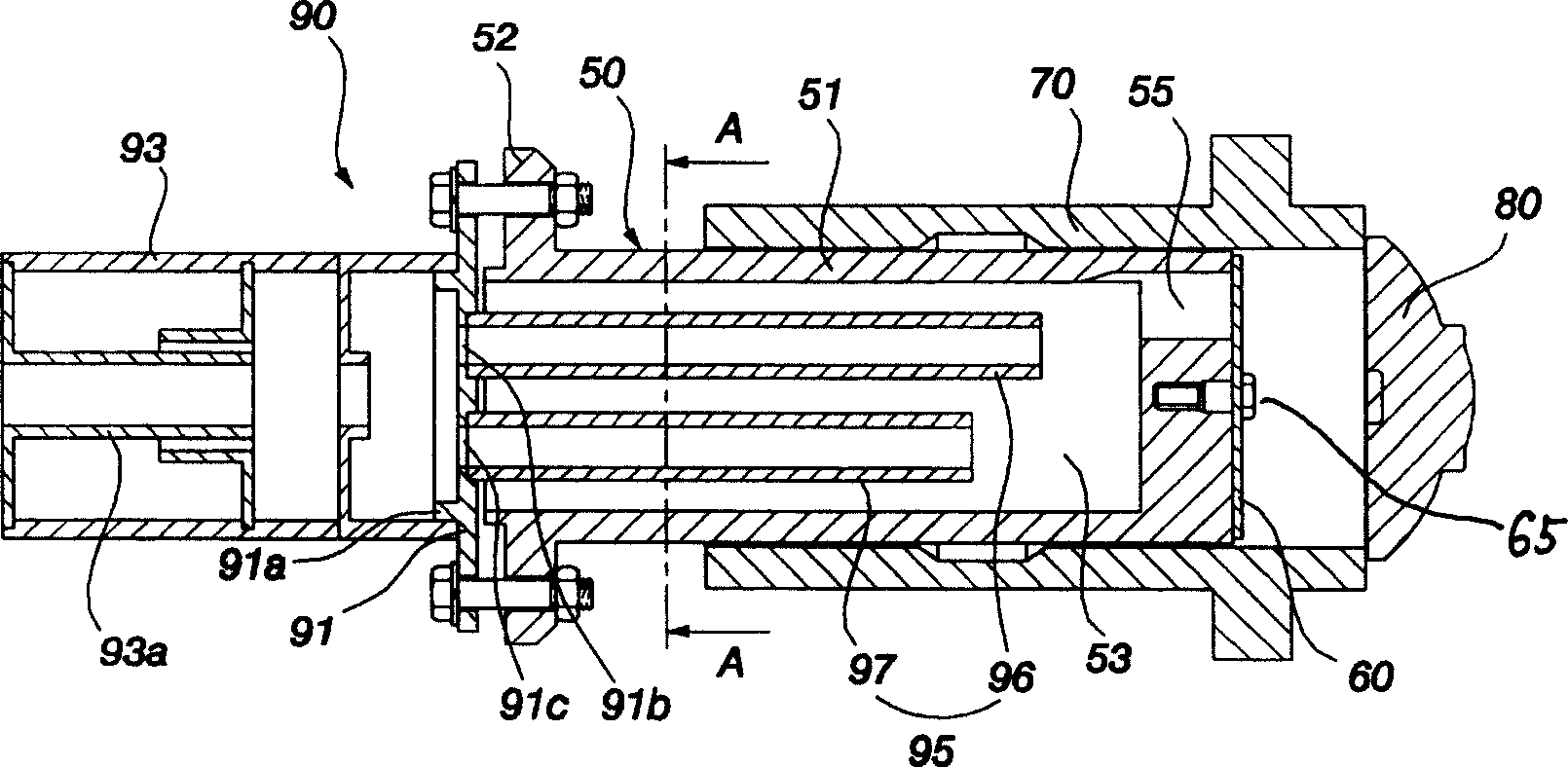

[0036] Such as image 3 As shown, the noise reduction device of the linear compressor of the present invention is provided with a muffler 90 on the rear side of the piston 50 .

[0037] The piston 50 is composed of a body part 51 and a flange part 52. The body part 51 is cylindrical and moves linearly inside the cylinder 70; the flange part 52 is fixed on the magnet frame (not shown in the figure). A suction flow path 53 is formed inside the main body portion 51 , and a suction port 55 is formed in a closed front portion.

[0038] A suction valve 60 that opens and closes the suction port 55 is provided on the front side of the piston 50 . The suction valve 60 is fixed to the front central portion of the piston 50 by a connecting member such as a screw 65 .

[0039] 80 is a discharge valve 80 for opening and closing the compression chamber of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com