High-frequency heating device, semiconductor manufacturing device, and light source device

A technology of high-frequency heating device and light source device, which is applied in semiconductor/solid-state device manufacturing, electric heating device, microwave heating, etc., can solve the problems of unpublished, unusable, broken filament, etc. High-speed directional control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0090] Next, a high-frequency heating device and a semiconductor manufacturing device according to an embodiment of the present invention will be described with reference to the drawings.

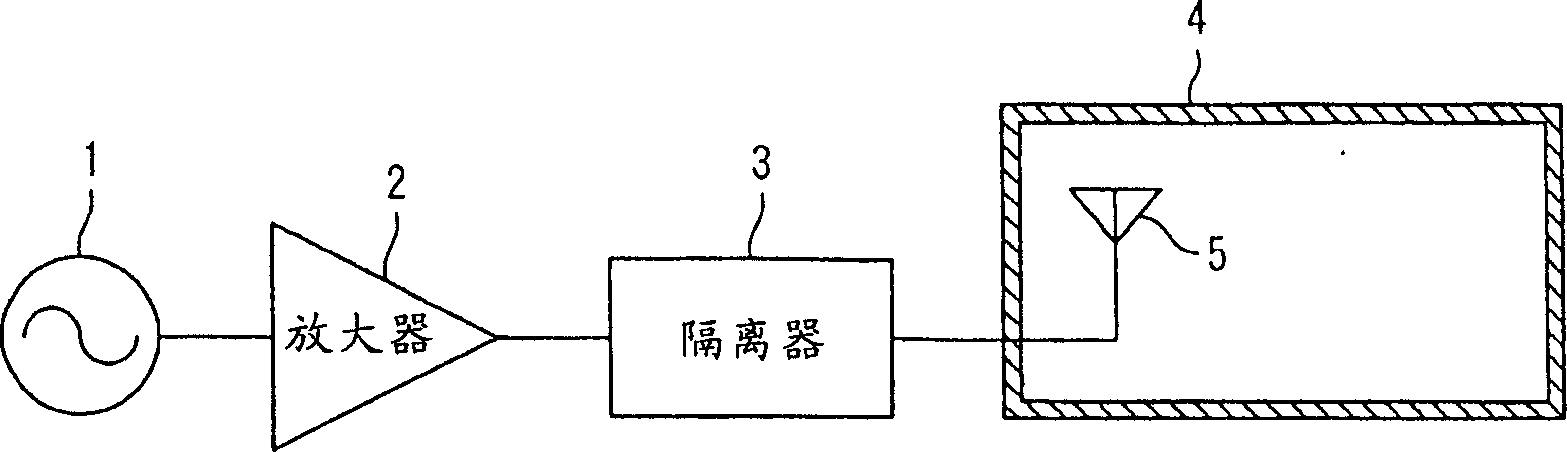

[0091] figure 1 It is a block diagram showing a schematic configuration of the high-frequency heating device according to the first embodiment of the present invention. In addition, specific examples of high-frequency heating devices include heaters such as microwave ovens and dryers.

[0092] figure 1 Among them, a metal cavity 4 is set in the high-frequency heating device, and an antenna 5 for irradiating microwaves is set in the metal cavity 4 . Here, the metal cavity 4 can efficiently seal microwaves irradiated from the antenna 5 without leaking to the outside. In addition, an object may be set in the metal cavity 4, for example, a substance containing moisture or the like may be set.

[0093] In addition, the high-frequency heating device is provided with: an oscillator 1 that gene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com