Automated fused biconical taper device for polarization maintaining fiber coupler

A technology of fused tapered and polarization-maintaining optical fiber, which is applied in the coupling direction of optical waveguide, can solve the problems of affecting the polarization extinction ratio of polarization-maintaining coupler, improper control of packaging time, high technical requirements, etc., and achieves simple and economical automatic production and realization of automation Production, the effect of compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, the present invention will be further described in detail with reference to the accompanying drawings.

[0056] Such as Figure 4 with Figure 5 As shown, the automatic polarization-maintaining fiber coupler fusion tapering device of the present invention mainly includes a working platform 1 and an automatic shaft alignment mechanism 3 installed on the working platform, an intermediate proximity mechanism 4, a fusion tapering mechanism 5 and an online packaging mechanism 6. . The working platform 1 is divided into a low platform 11 and a high platform 12 in a step-like manner. On the low platform 11, a left mechanical platform 21 and a right mechanical platform 22 and a control panel 9 are arranged symmetrically.

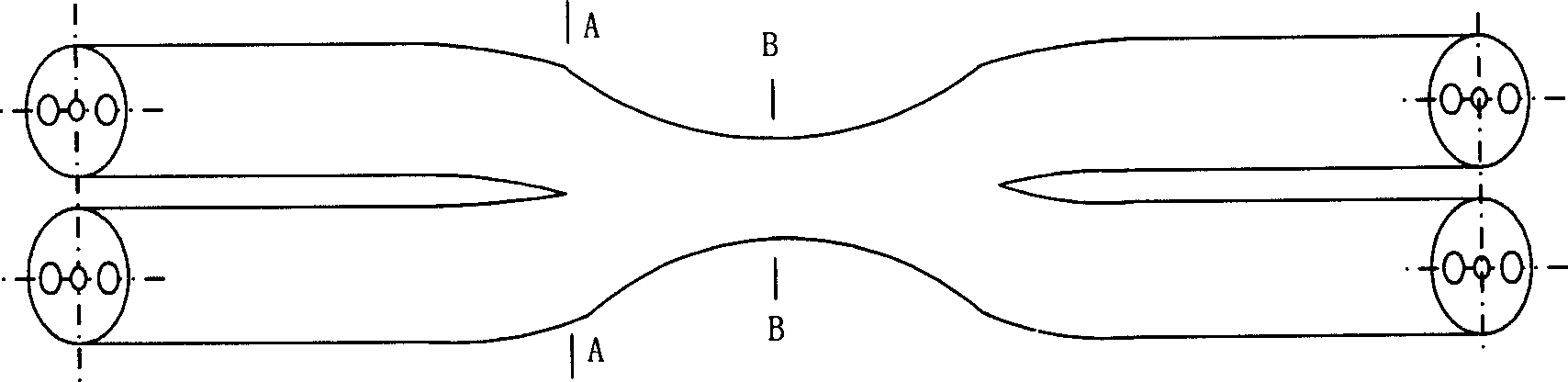

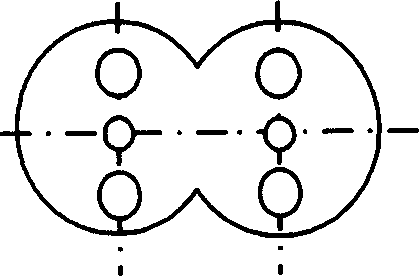

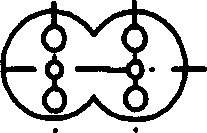

[0057] Automatic shaft alignment is the key to realize the production of polarization-maintaining couplers, such as Figure 6 , Figure 7 As shown, the automatic axis alignment mechanism 3 of the present invention includes four groups of electric rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com