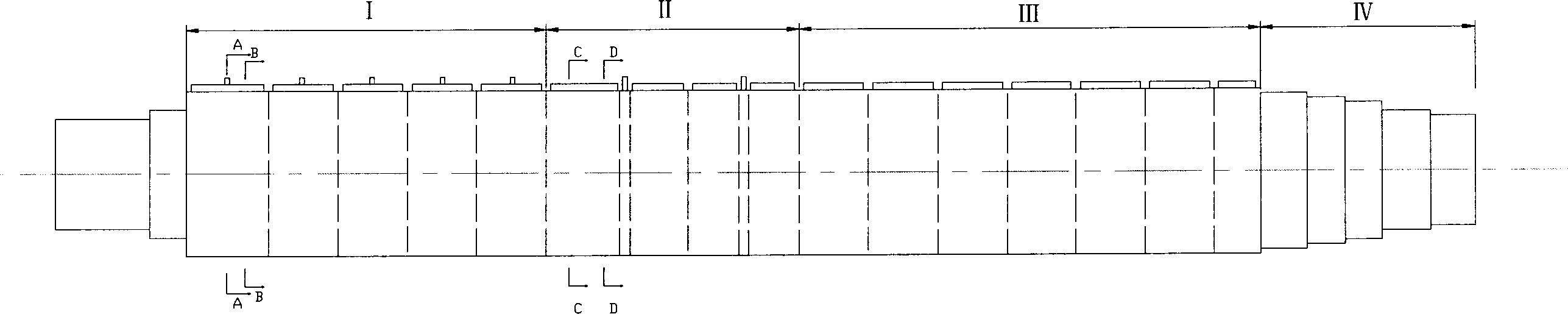

Firebox structure of pusher plate kiln in calcining apparatuses for preparing alloy of vanadium-nitrogen continously

A technology of furnace structure and vanadium-nitrogen alloy, which is applied in the field of vanadium-nitrogen alloy, can solve the problems of extremely serious oxidation erosion of graphite lining and small oxidation erosion of graphite material in the inner cavity, so as to improve service life, prevent corrosion and ensure normal operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

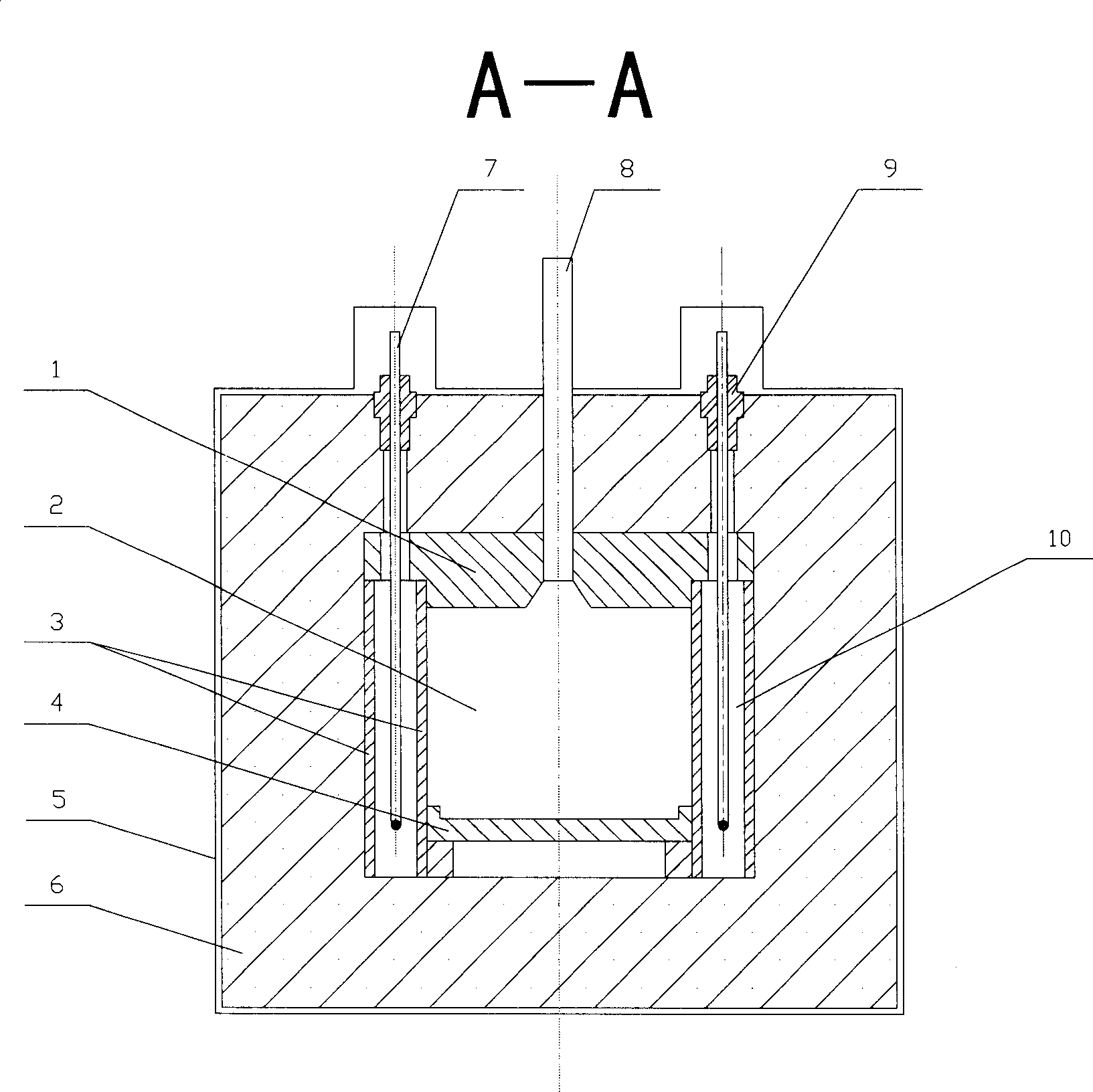

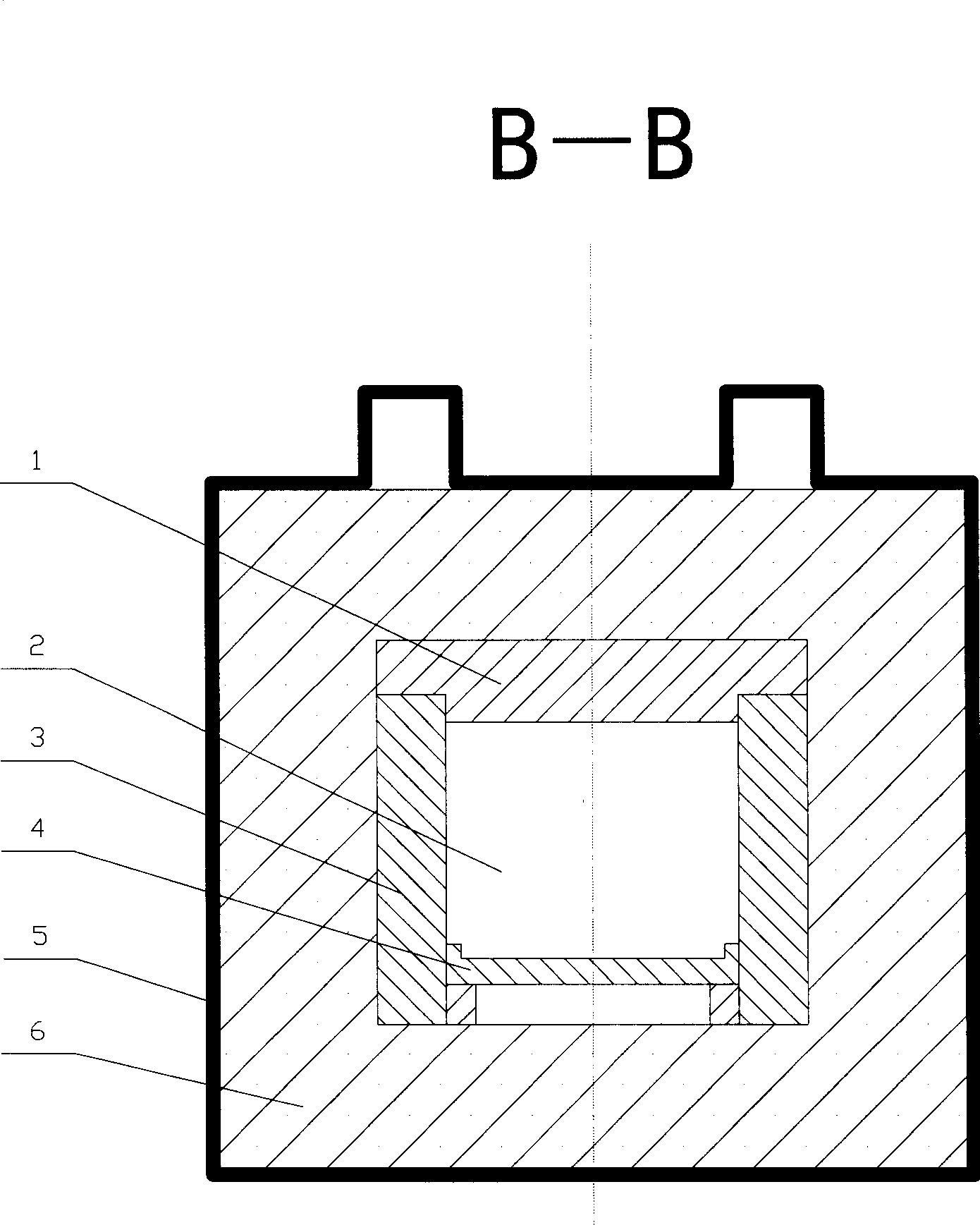

Method used

Image

Examples

Embodiment 1

[0025] Before the implementation of the present invention, corundum was used as the lining material for the inner lining of each temperature zone of the pusher kiln, and the heating element chamber was not isolated from the furnace. The service life of the pusher kiln was only about 25 days, and the replacement frequency of the heating element was 8.2 pieces / day, the power-off frequency of push plate kiln is 3.7 times / day.

Embodiment 2

[0027]Before the implementation of the present invention, the lining materials of the push plate kiln were made of graphite, and the heating element cavity in the 6-7 temperature zone was isolated from the furnace. The power-off frequency of push plate kiln is 2.6 times / day.

Embodiment 3

[0029] In the implementation of the technical solution of the present invention, the lining of the low-temperature section, the rear of the transition section and the high-temperature section of the push plate kiln are all made of graphite materials, and the side walls and tracks at the front of the transition section are made of high-purity fused magnesia bricks and top bricks. For graphite bricks up to 200mm thick, the heating element cavity of each temperature zone is isolated from the furnace, and the furnace height of the 8 temperature zone is 80mm lower than that of other temperature zones. After the implementation, the service life of the pusher kiln has been increased to 220-240 days, the frequency of replacement of heating elements has been reduced to 0.8 pieces / day, and the frequency of power failure is 1-2 times / month.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com