Method for fabricating artware by using pieces of hard walhut hull

A handicraft and walnut shell technology, which is applied in the field of handicrafts made of hard walnut shell slices, can solve the problems of handicraft deformation, soft mold easy extrusion deformation, etc., and achieve the effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

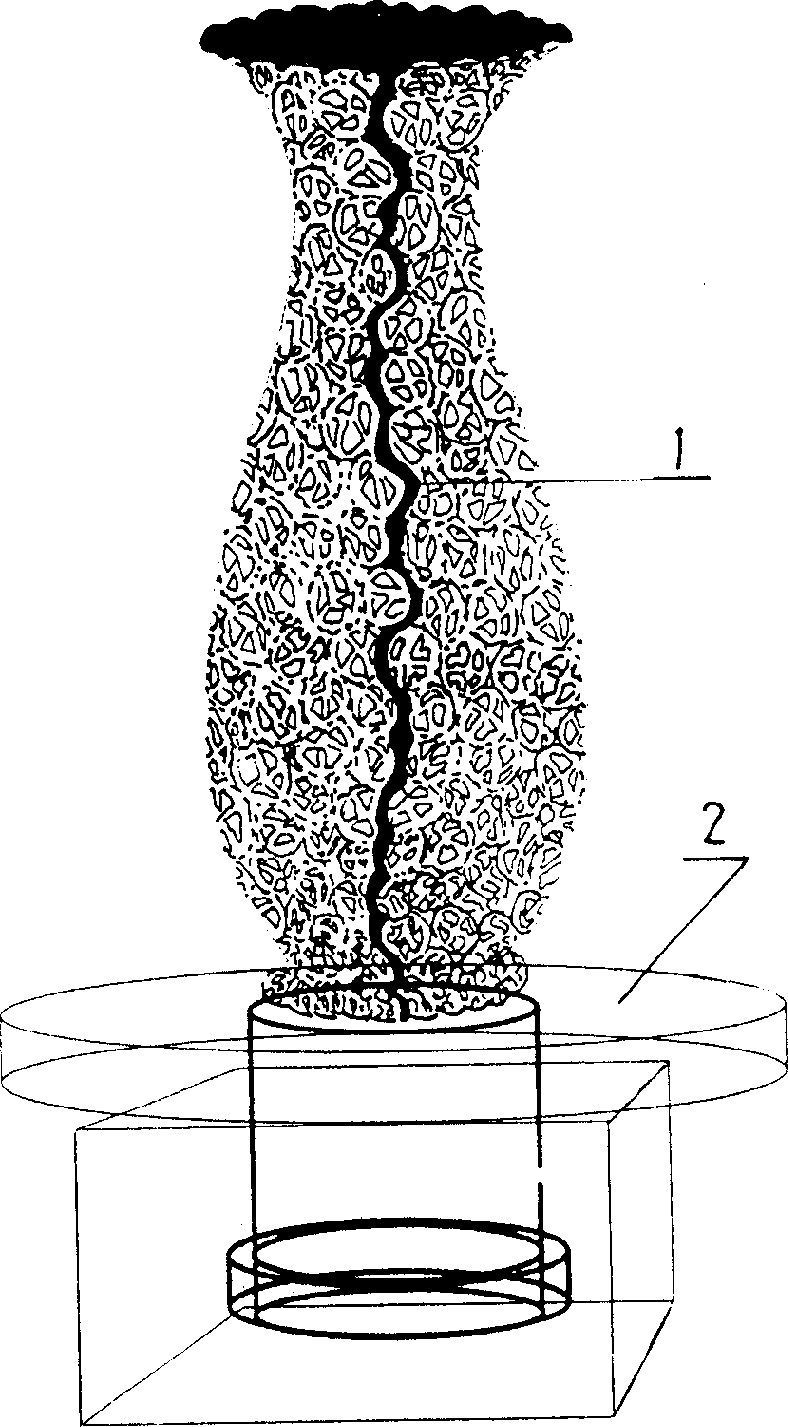

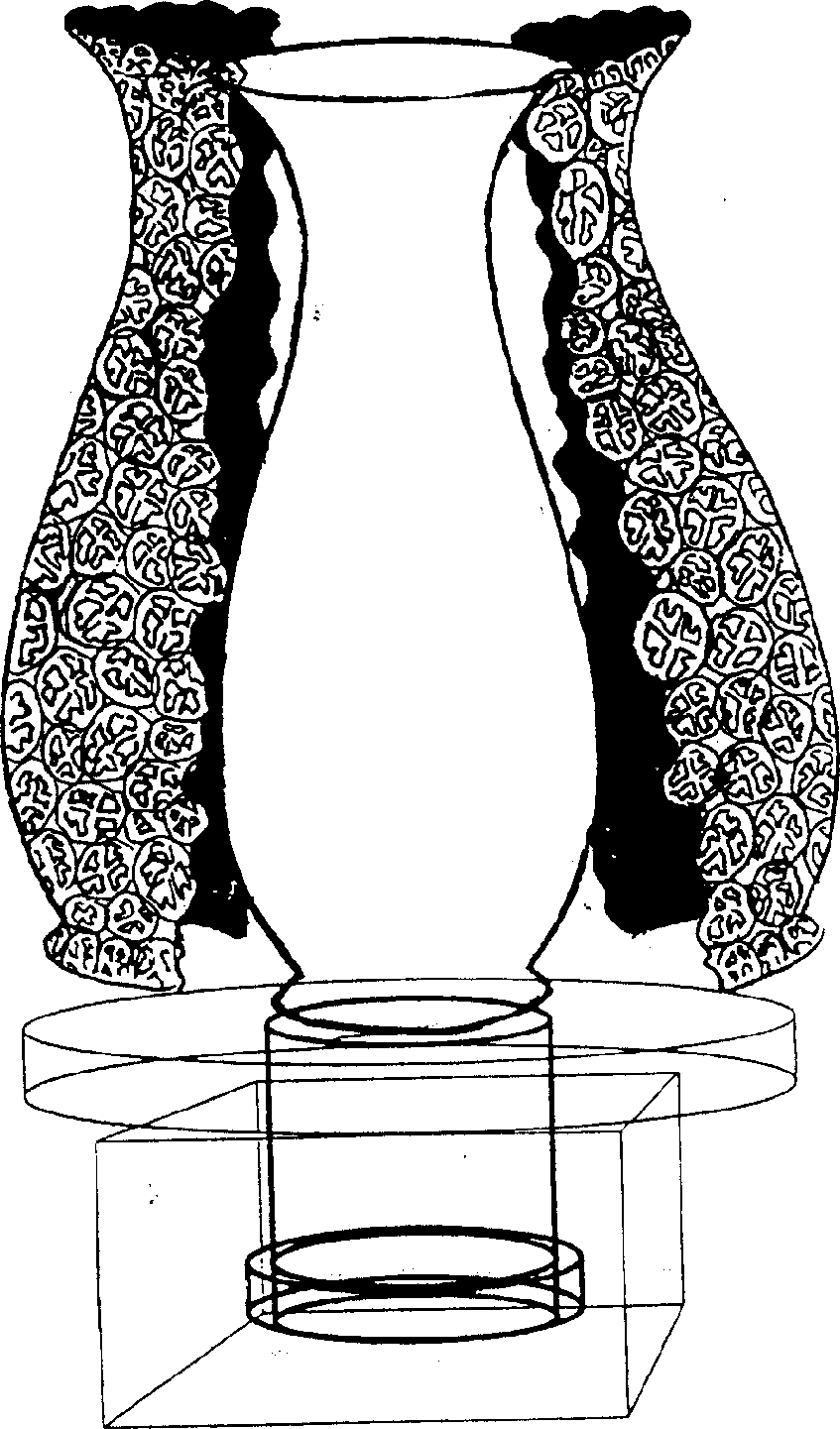

[0011] The present invention is described further with regard to accompanying drawing now, and what illustrated in accompanying drawing is a vase making. In the schematic diagram, the hard mold is in the vase, the hard mold is placed on the rotatable platform 2, and the mold release agent (glycerin) is evenly applied on the hard mold. Paste the hard walnut shell sheet from bottom to top by the hard mold then, between the hard walnut shell sheet earlier use instant bonding agent (502 classes) to make temporary fixation. During this process, the rotatable platform can be rotated slightly continuously, and the hard walnut shells are pasted on the hard mold in turn. After the whole mold is pasted, resin glue can be applied between the hard walnut shells. In the process of coating resin glue, two centerlines 1 not coated with resin glue will be left on the handicraft prototype on the hard mold. The effect of these two midlines is that this handicraft can be divided into two and ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com