Method for preparing complete soluble instant powder of green bean

An instant powder and fully dissolving technology, applied in food preparation, dairy products, milk substitutes, etc., can solve the problems of low mung bean utilization and incomplete dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

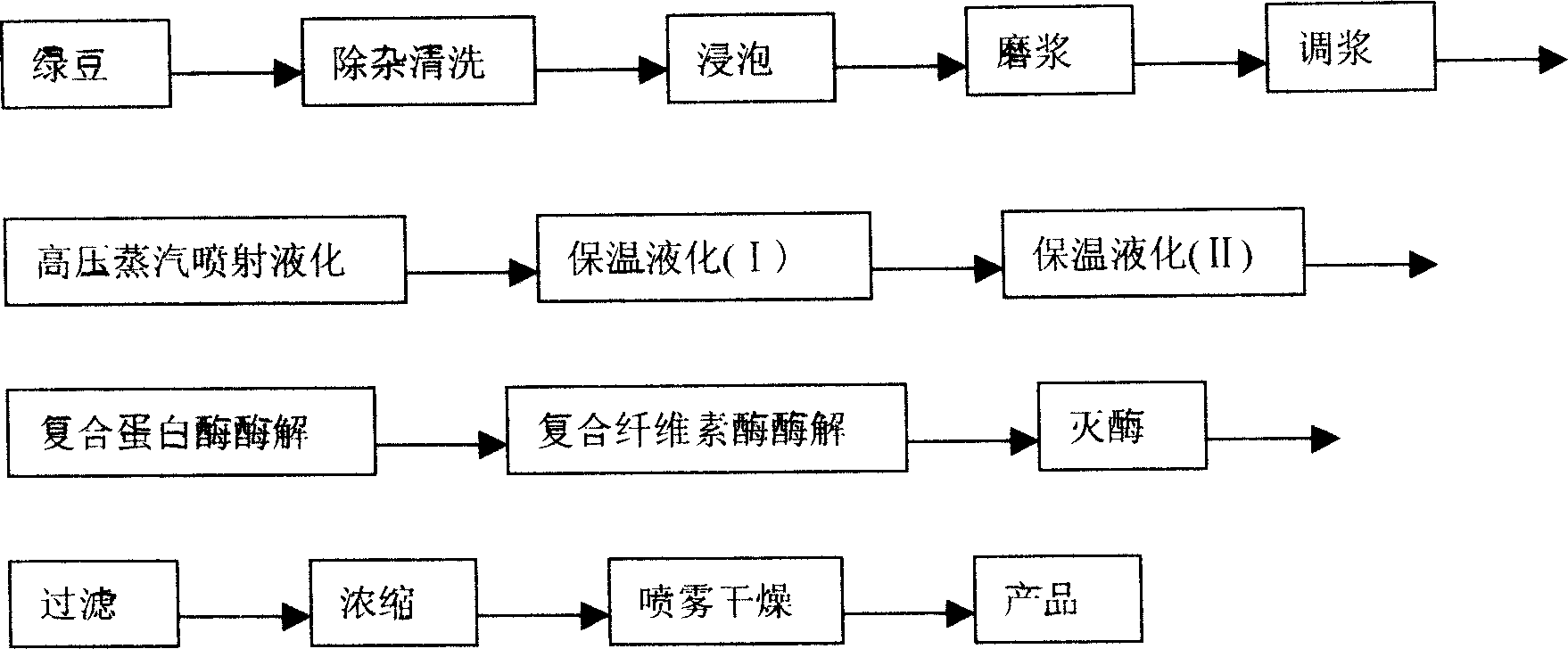

[0007] Embodiment one, as figure 1 Shown, the present invention takes following process step:

[0008] (1) Mung bean screening: select mung beans with full grains, no insect bites and no mildew;

[0009] (2) Impurity removal and cleaning: use winnowing to remove the remaining sundries with small specific gravity; sieve to remove sundries such as sediment and stones; wash to further remove the rest of the sundries and drain;

[0010] (3) Soaking: Soak at room temperature, soak for 12 hours in summer, soak until the mung bean skin partially swells but does not fall off, drain;

[0011] (4) Refining: about 2 times the amount of wet mung bean, grind it into mung bean milk with an electric stone mill, and the slurry particles pass 20 meshes;

[0012] (5) pulping: add water until the mung bean milk contains 15% solids, adjust the pH value to 6.2 with sodium carbonate, add α-high temperature resistant amylase, the dosage is 0.7% of the dry mung bean weight; the pulping process is n...

Embodiment 2

[0022] Embodiment two, such as figure 1 Shown, the present invention takes following process step:

[0023] (1) Mung bean screening: select mung beans with full grains, no insect bites and no mildew;

[0024] (2) Impurity removal and cleaning: use winnowing to remove other sundries with small specific gravity; sieve to remove sundries such as silt and stones; wash with water to further remove other sundries and drain;

[0025] (3) Soaking: Soaking at room temperature, 16 hours in winter, soaking until the mung bean skin partially swells but does not fall off, drain;

[0026] (4) Refining: about 4 times the water of wet mung beans, grind the mung bean milk with a 45A pulverizer, and pass the slurry particles for 20H;

[0027] (5) pulping: add water until the mung bean milk contains 25% solids, adjust the pH value to 6.8 with sodium carbonate, add α-high temperature resistant amylase, the dosage is 1.2% of the dry mung bean weight; the pulping process is not heated;

[0028] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com