Gas sensor

A gas sensor and sensor element technology, which is applied to instruments, scientific instruments, measuring devices, etc., can solve the problems of increasing the stability time and reducing the performance of the gas sensor, and achieve the effect of preventing condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

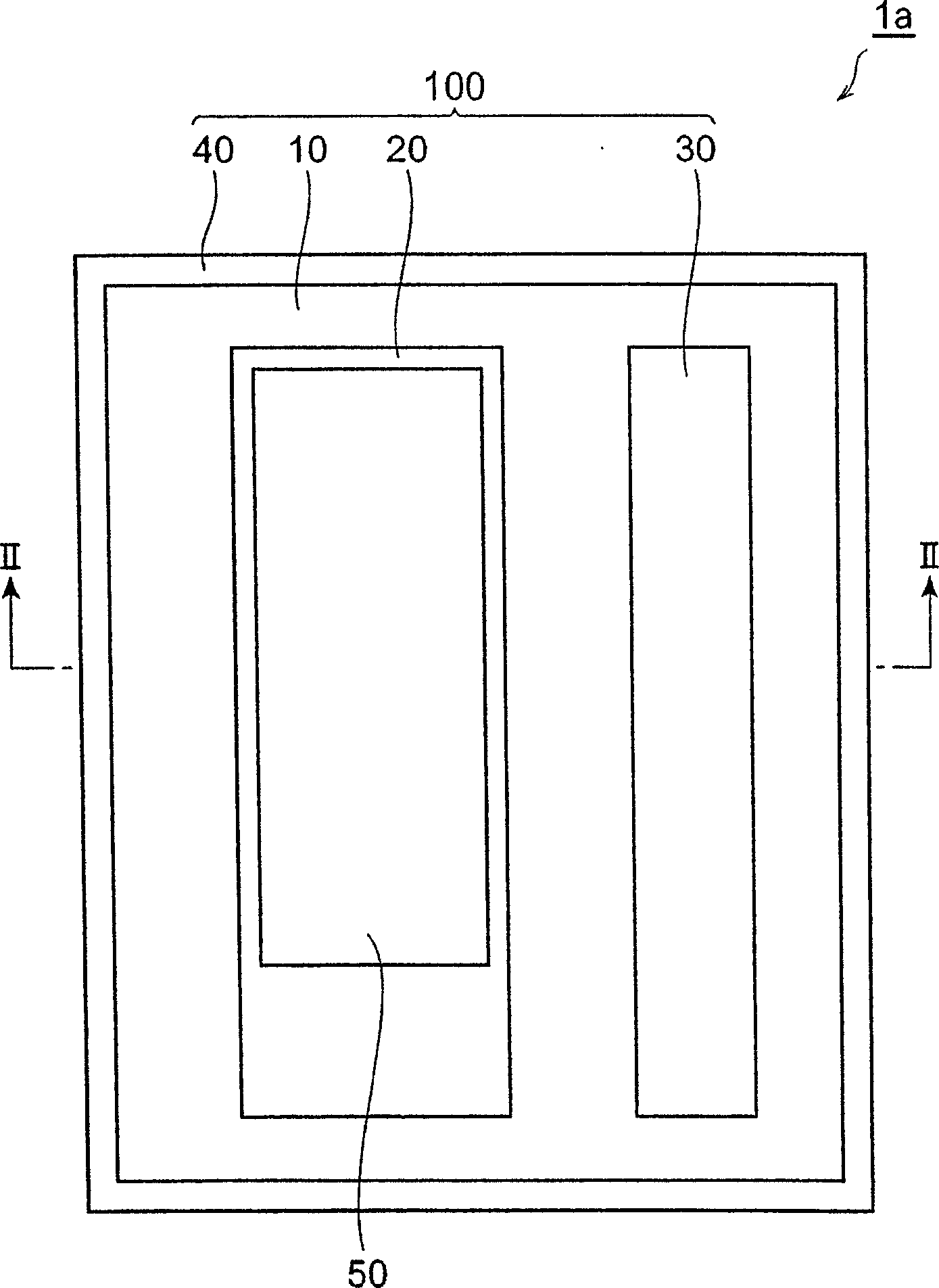

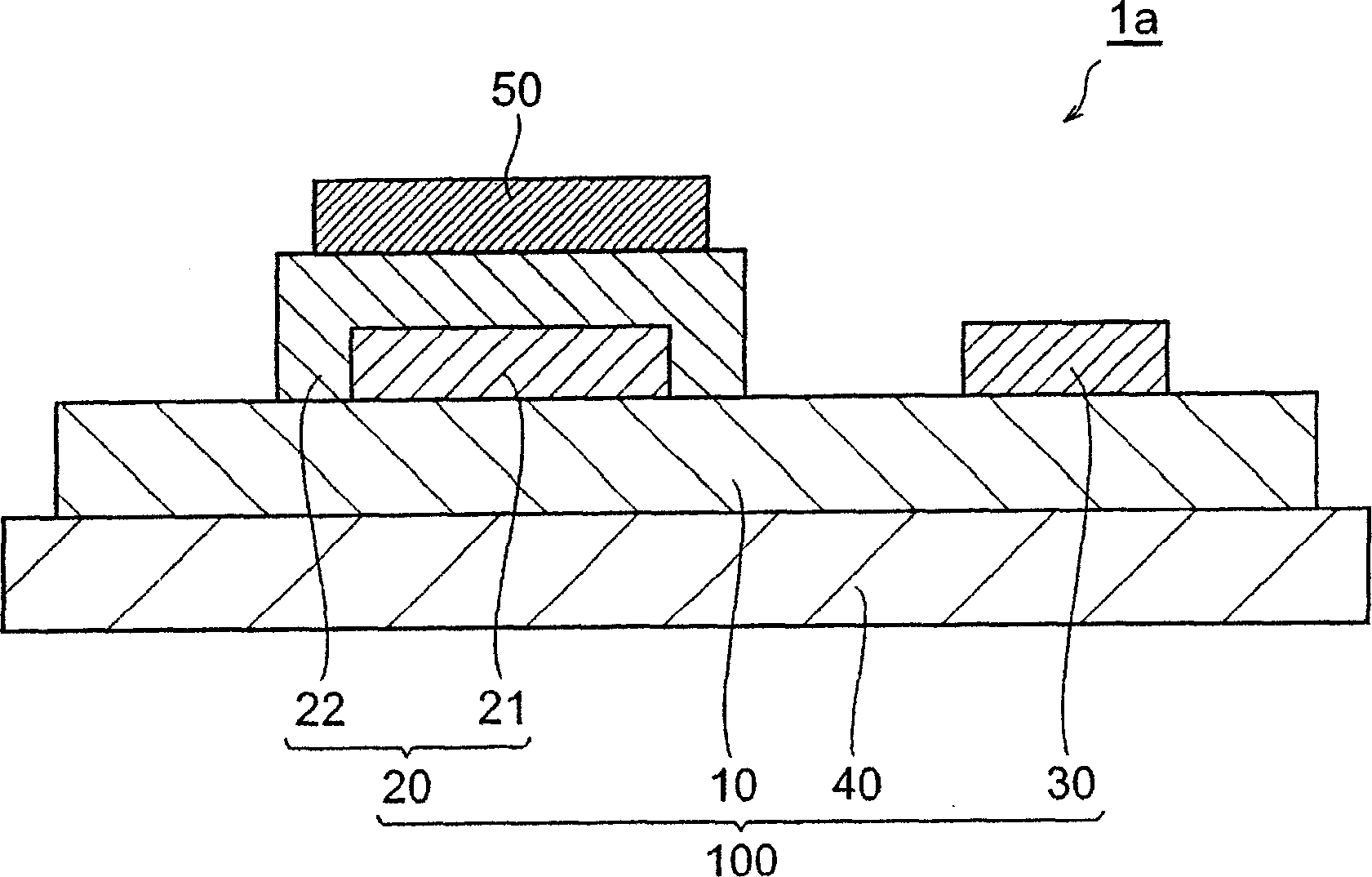

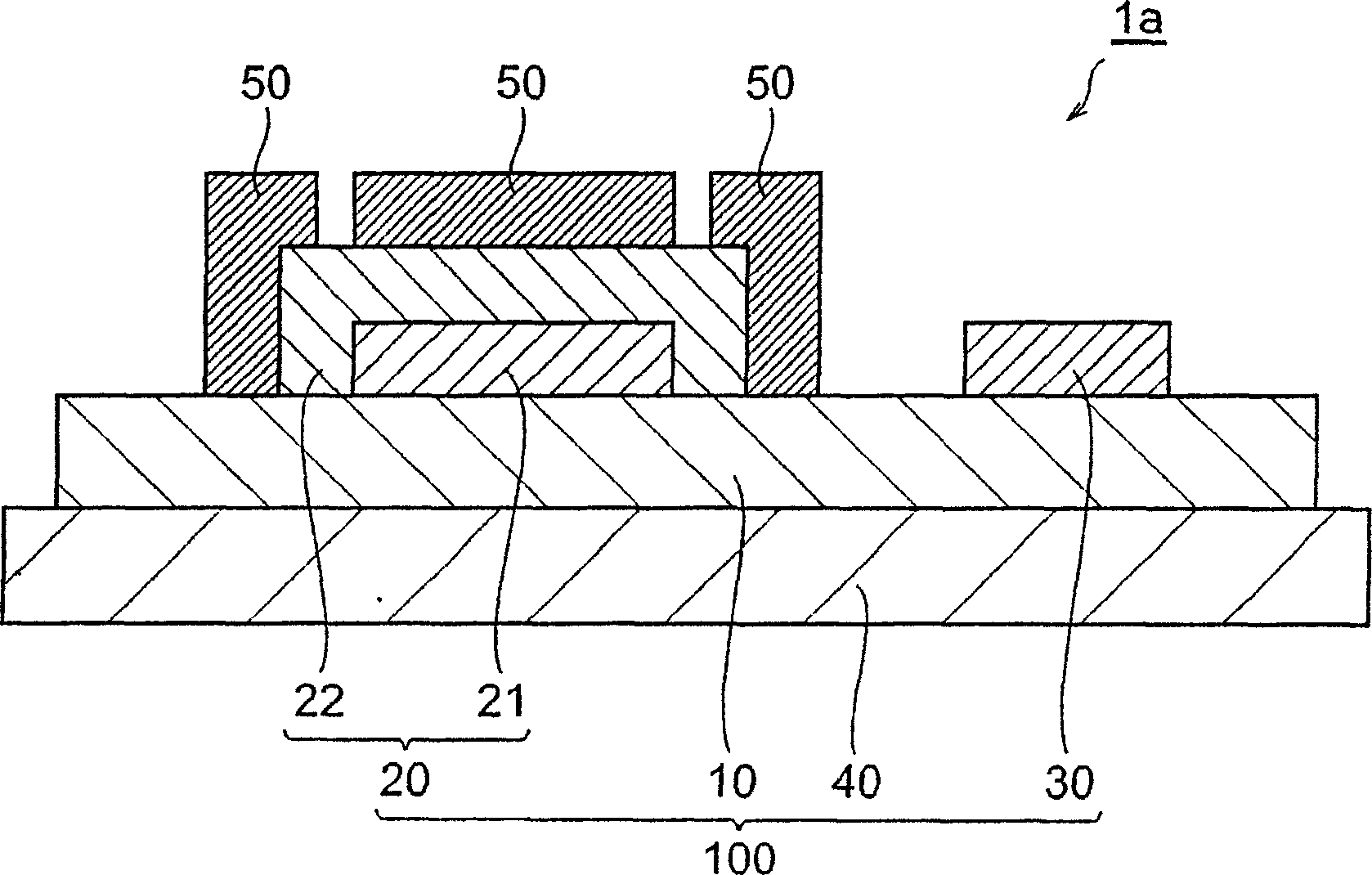

[0052] As follows, the production has the same figure 1 with figure 2 A carbon dioxide gas sensor of the same configuration as the gas sensor 1a shown in . First, a 0.5 mm thick NASICON substrate having a rectangular main surface (4 mm×4 mm) was prepared as a solid electrolyte substrate, and a 0.1 μm thick metal layer made of Au and a counter electrode were formed on the NASICON substrate by sputtering. Then, a gas detection part with a thickness of 20 μm was formed using a mixture of a compound salt of barium carbonate and lithium carbonate and indium oxide as a gas detection material covering only the metal layer of the detection electrode by a coating method. A Pt thin film was also formed as a heating portion on the surface of the NASICON substrate opposite to the gas detection portion by sputtering to obtain a gas sensor element portion.

[0053] Next, the upper surface of the gas detection part of the detection electrode was covered by coating method to form a moistur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com