Pneumatic instrument for measuring outside diameter of thin-wall bearing

A technology of pneumatic measuring instrument and thin-walled bearing, which is used in mechanical bearing testing, measuring devices, instruments, etc., to achieve the effect of long service life, convenient operation and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

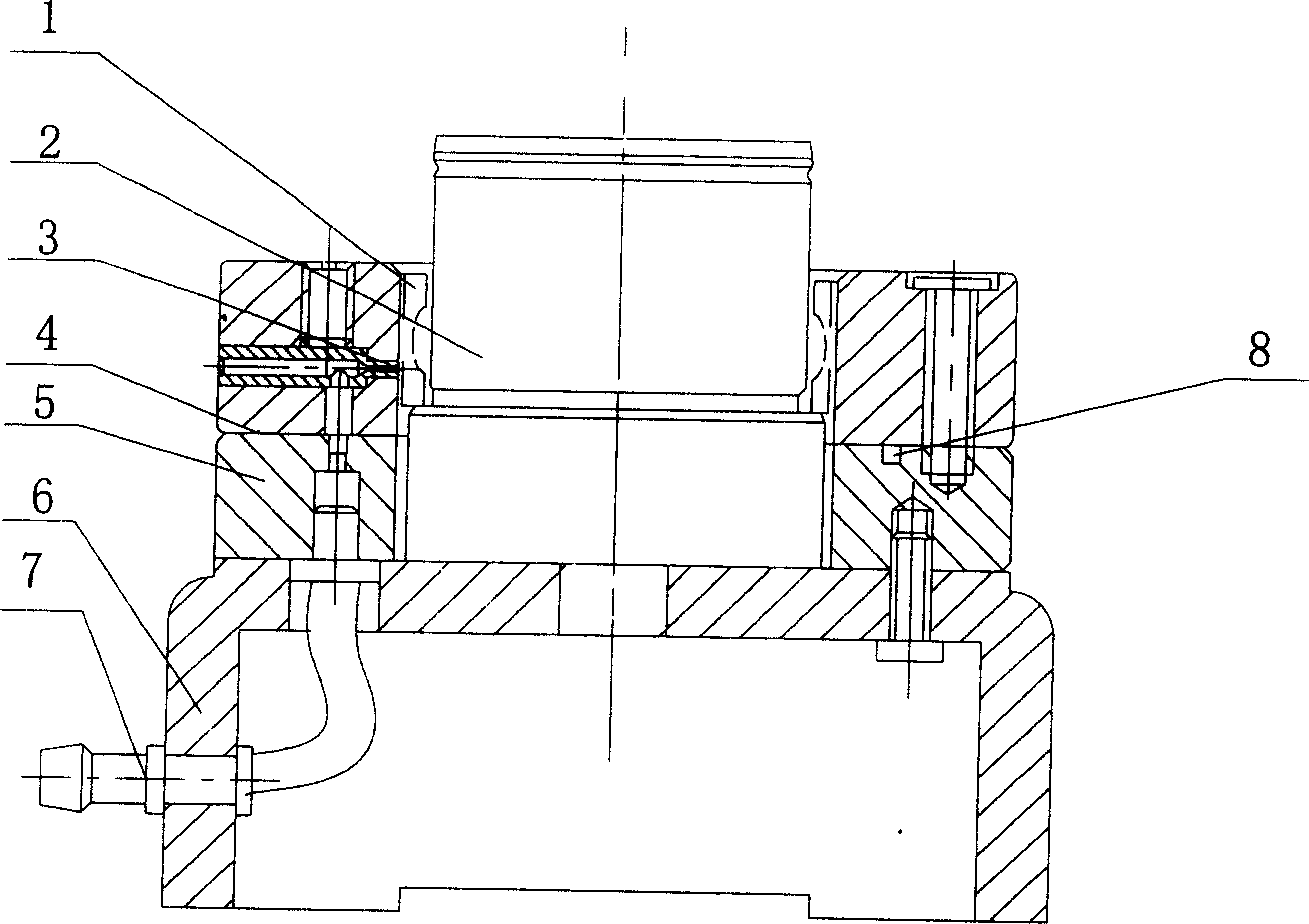

[0028] Specific embodiments of the present invention are described with reference to the accompanying drawings.

[0029] As shown in FIG. 1, the present invention mainly includes a gas-electric converter 9 (existing), an electronic display 10 (existing) and a pneumatic probe 4. The pneumatic probe 4 adopts a circular structure and is placed on a measuring device , there are eight or more even-numbered measuring nozzles 3 (8 measuring nozzles are used in this implementation) evenly distributed in the circumferential direction of the probe, which is to spray the compressed air through the nozzle 3 to the outer diameter of the bearing ring 1 placed inside it , the pneumatic probe 4 changes the airflow pressure into the change of the length value according to the induction, converts it through the pneumatic-electric converter 9, and makes the electronic display 10 display the measured value through the amplifier 11 and the drive circuit 12.

[0030] like figure 2 As shown, the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com