Process for extracting platinum metals from ore containing platinum metal

A technology of platinum group metals and ores, applied in the field of extraction of platinum group metals, can solve the problems of long production cycle, many equipments, large investment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: In the ore of the above-mentioned raw materials, 2000g is optionally divided into 2 groups, and the two groups are respectively ground to 100-120 mesh, put into a microwave heating container and heated for 10min, and then the ore is mixed with 1mol / L H 2 SO 4 , according to the solid-to-liquid ratio of 1:4~5 to make a slurry, put it into a container with an ultrasonic stirrer and stir for 45 minutes, pump the slurry into a microwave heating container and heat it for 30-45 minutes, the temperature is controlled at 85°C~95°C, and then When cooled to 30°C to 35°C, concentrates are obtained after mixing with water and pressure filtration, and measured after drying: 165g concentrates for the first group and 168g concentrates for the second group.

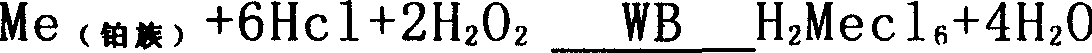

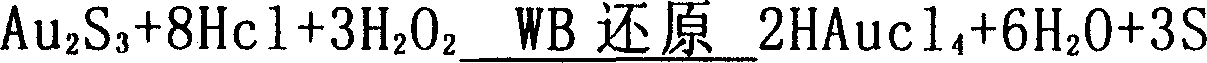

[0037] The 165g fine sand of the first group is made into a slurry with a solid-to-liquid ratio of 1:5 with 8mol / L Hcl liquid, and when the slurry is heated to 85°C by microwave, 45-50ml of H 2 o 2 , control the tempe...

Embodiment 2

[0038] Embodiment 2: use the 2nd group to operate by the same process of embodiment 1, obtain the noble liquid of the mixed chloric acid of platinum group, obtain slag rate 83.6%, adopt reducing extraction process, cooperate spectrophotometer to detect in addition, and in table 1 In contrast, the total extraction rate of the platinum group reached 94.8%.

Embodiment 3

[0039] Embodiment 3: In the "black rock series" of 1,000 tons piled up in the factory, select 4000g ore and divide it into 2 groups, and the two groups use the pretreatment method in the process flow respectively to obtain two groups of 2000g pretreated fine ore sand : One set is 328g and the other is 332g.

[0040] Use 8mol / L Hcl and the first group of 328g concentrated ore to mix the slurry, the solid-liquid ratio is 1:4, use microwave to heat up to 85°C, and start adding about 100ml of H 2 o 2 Raise the temperature to 95°C, and control the temperature within 95°C, cool to 30-35°C after 30 minutes, filter and wash with an equal amount of distilled water, combine the washing and filtrate to obtain a platinum group metal chlorohydric acid mixed precious solution, and extract the residue The rate is 84.85%. When using reduction, extraction and other processes and spectrophotometric detection, the extraction rate close to the content in Table 1 is obtained: 93.8%

[0041] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com