Compound semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as fixed deterioration, yield reduction, and reliability deterioration, so as to ensure insulation and finished products The effect of improving the rate and improving the characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

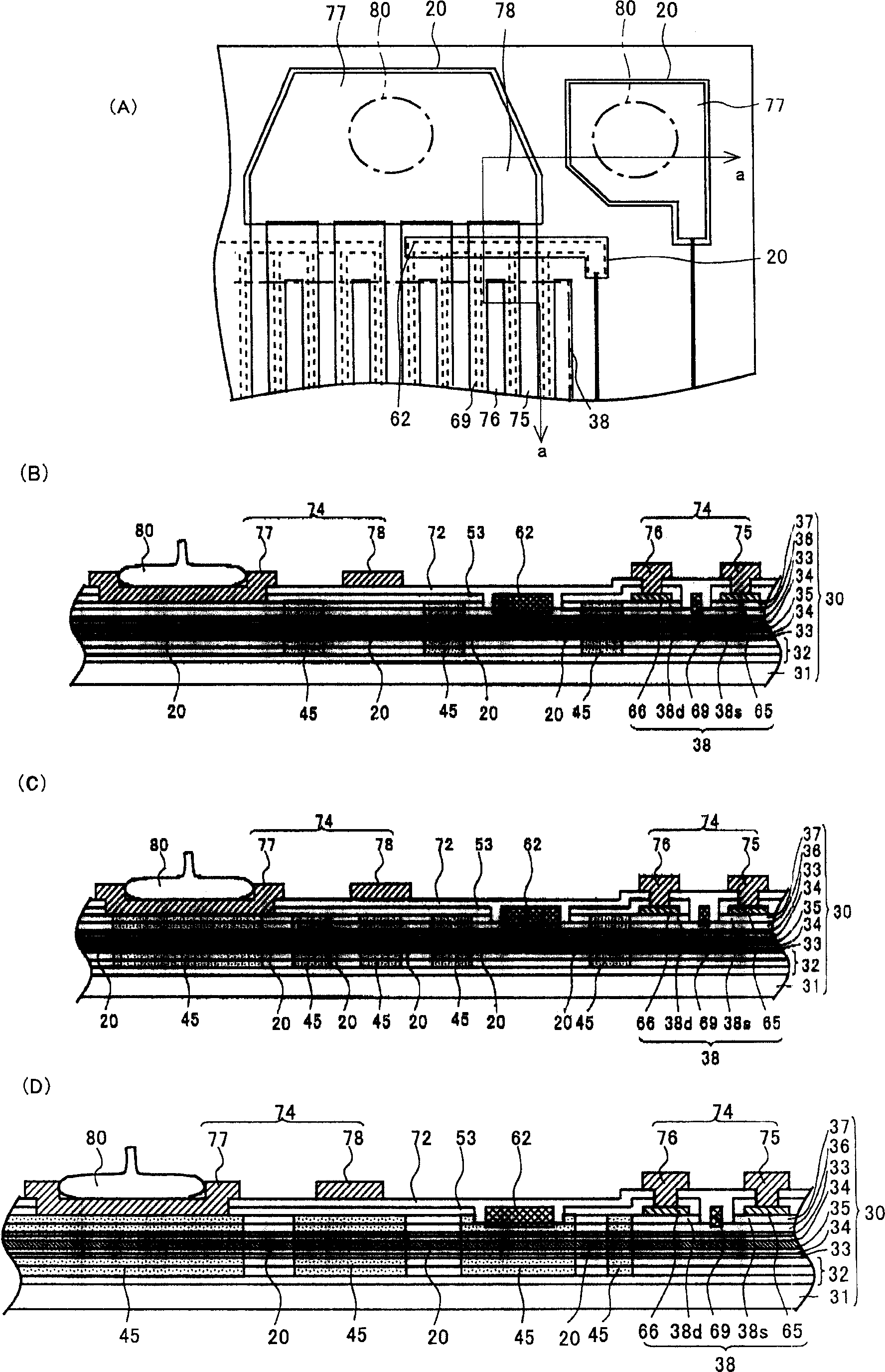

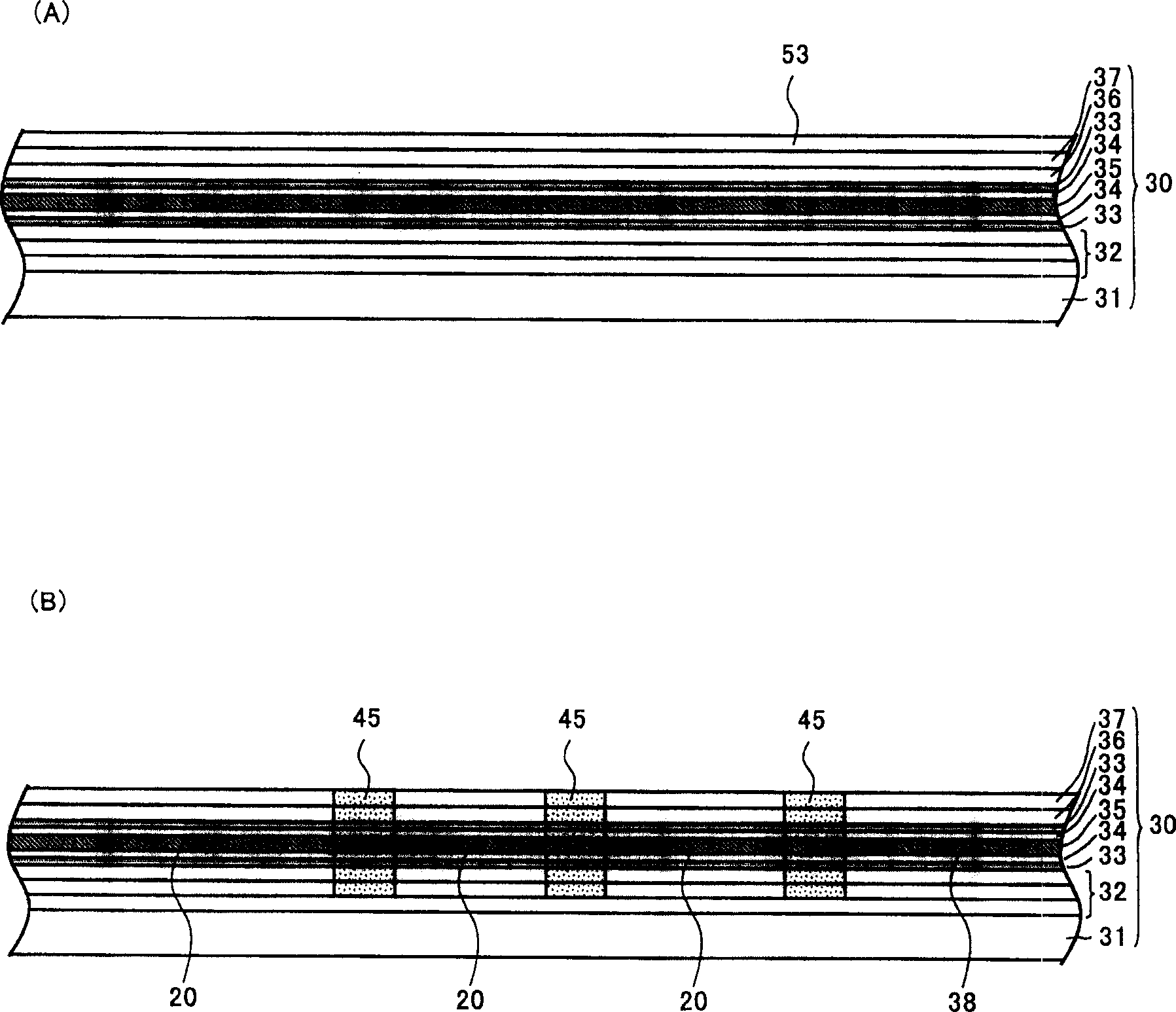

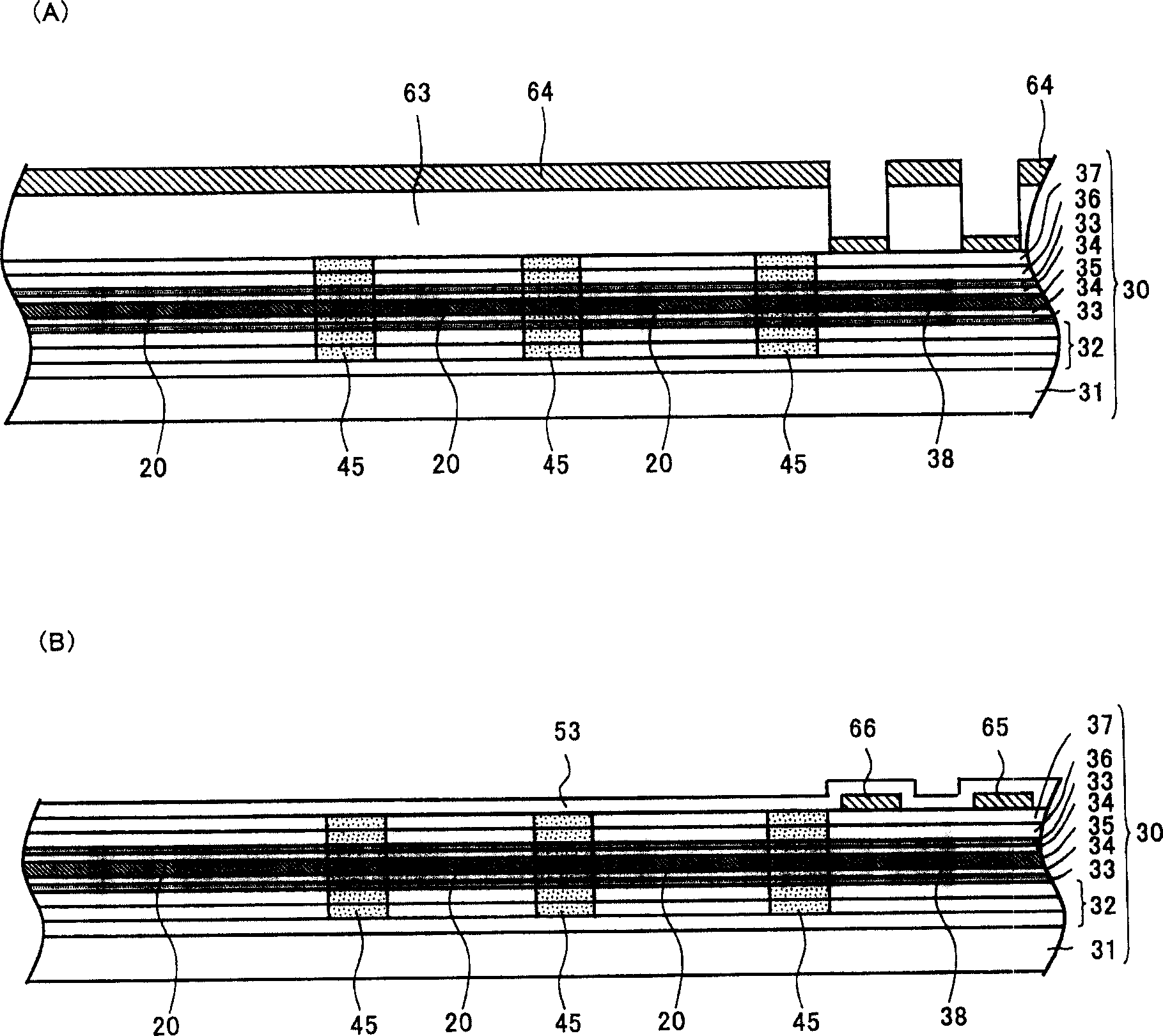

[0101] Refer below Figure 1 to Figure 8 Embodiments of the present invention will be described, and the configuration will be described as an example. Figure 9 A HEMT (High Electron Mobility Transistor: High Electron Mobility Transistor) such as a switch circuit device (SPDT), electrode pads, and wiring portions are shown.

[0102] figure 1 is a diagram showing an example of the compound semiconductor device of this embodiment, figure 1 (A) is a floor plan, figure 1 (B) is a-a line sectional view. In addition, the same symbols are used for the same constituent elements as in the prior art.

[0103] Such as figure 1(A), (B), method of forming the substrate 30 Firstly, the non-doped buffer layer 32 is laminated on the semi-insulating GaAs substrate 31 . The buffer layer is often formed from multiple layers. Then, an n+ type AlGaAs layer 33 as an electron supply layer, an undoped InGaAs layer 35 as an electron transit layer, and an n+ type AlGaAs layer 33 as an electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com