Improved cylinder gluer

A gluing machine and rotary screen technology, which is applied in the direction of optical mechanical equipment, screen printing method, photoplate making process of pattern surface, etc., can solve the problems affecting the quality of rotary screen printing gluing, cumbersome, uneven gluing, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

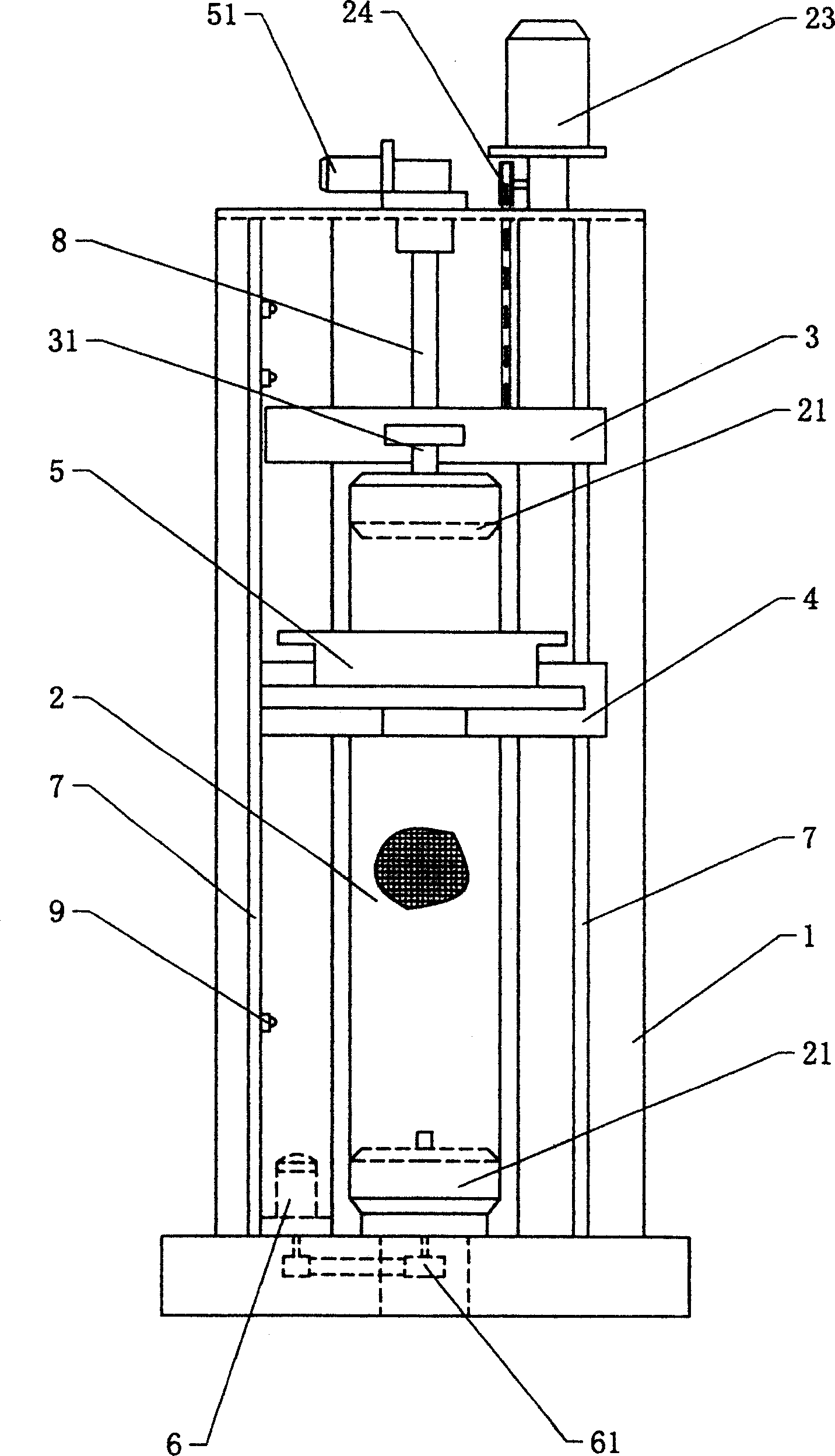

[0010] With reference to accompanying drawing, a kind of improved rotary screen gluing machine of the present invention is: comprise frame 1, be provided with the rotary screen seat 21 that can be used for installing rotary screen 2 on the bottom plate of frame 1, set on frame 1 There is a rotary screen seat clamp 31 and a corresponding clamp slide 3 that can be matched with the rotary screen base 21. The clamp 31 is fixed on the clamp slide 3 and moves together with the clamp slide 3. The surface of the outer circumference is provided with a gluing pot 5 and a corresponding gluing pot seat 4, the gluing pot 5 is fixed on the gluing pot seat 4 and moves together with the gluing pot seat 4, and a lead screw 8 is arranged on the frame 1 And the linear guide 7, in order to improve the stability of the movement of the gluing pot seat 4 and the gluing pot 5 and the precision of the transmission, the screw 8 can use a ball screw, while the linear guide 7 can use a rolling linear guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com