Aluminium slab ingot gantry saw cutter of disk

A gantry type, sawing machine technology, applied in shearing devices, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems of slow cutting speed, low cutting precision, low efficiency, etc. High precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

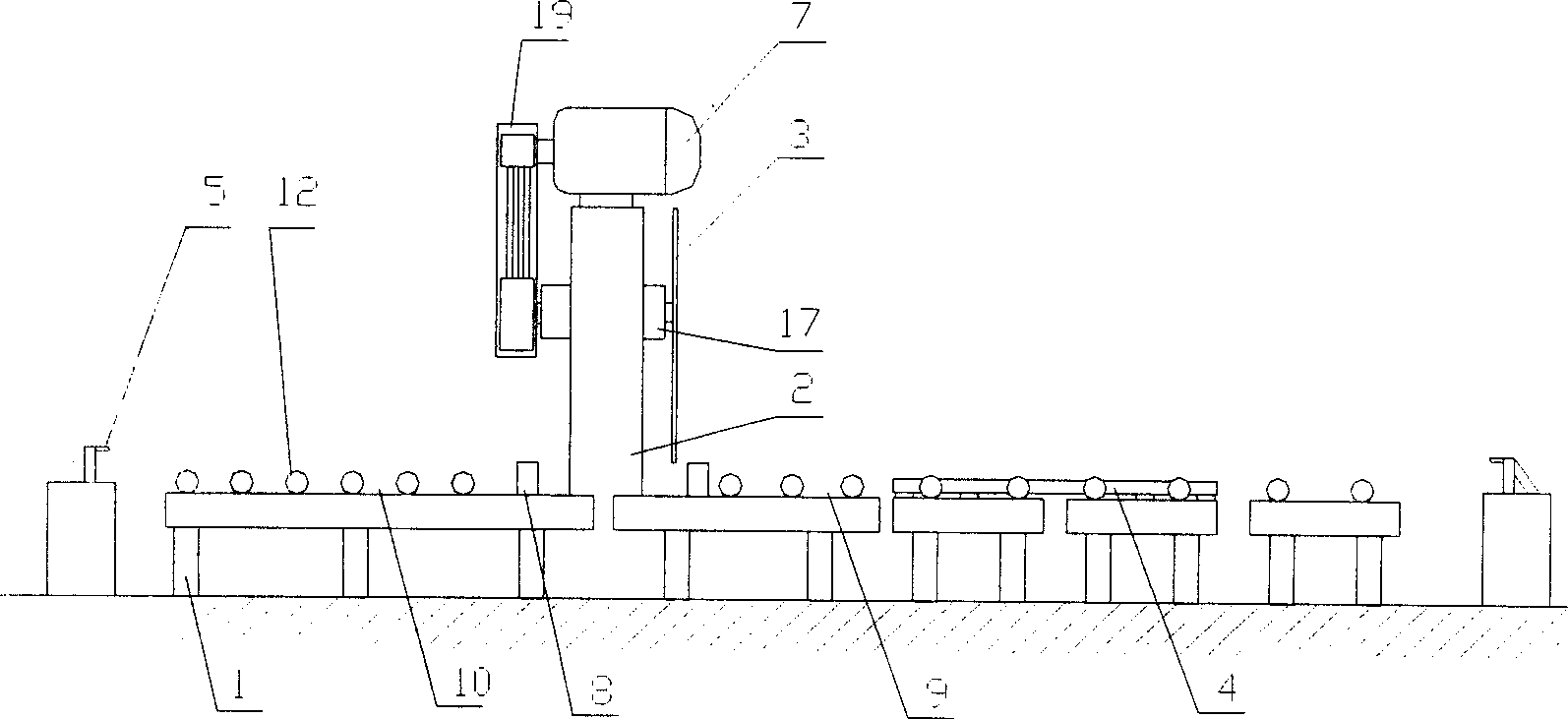

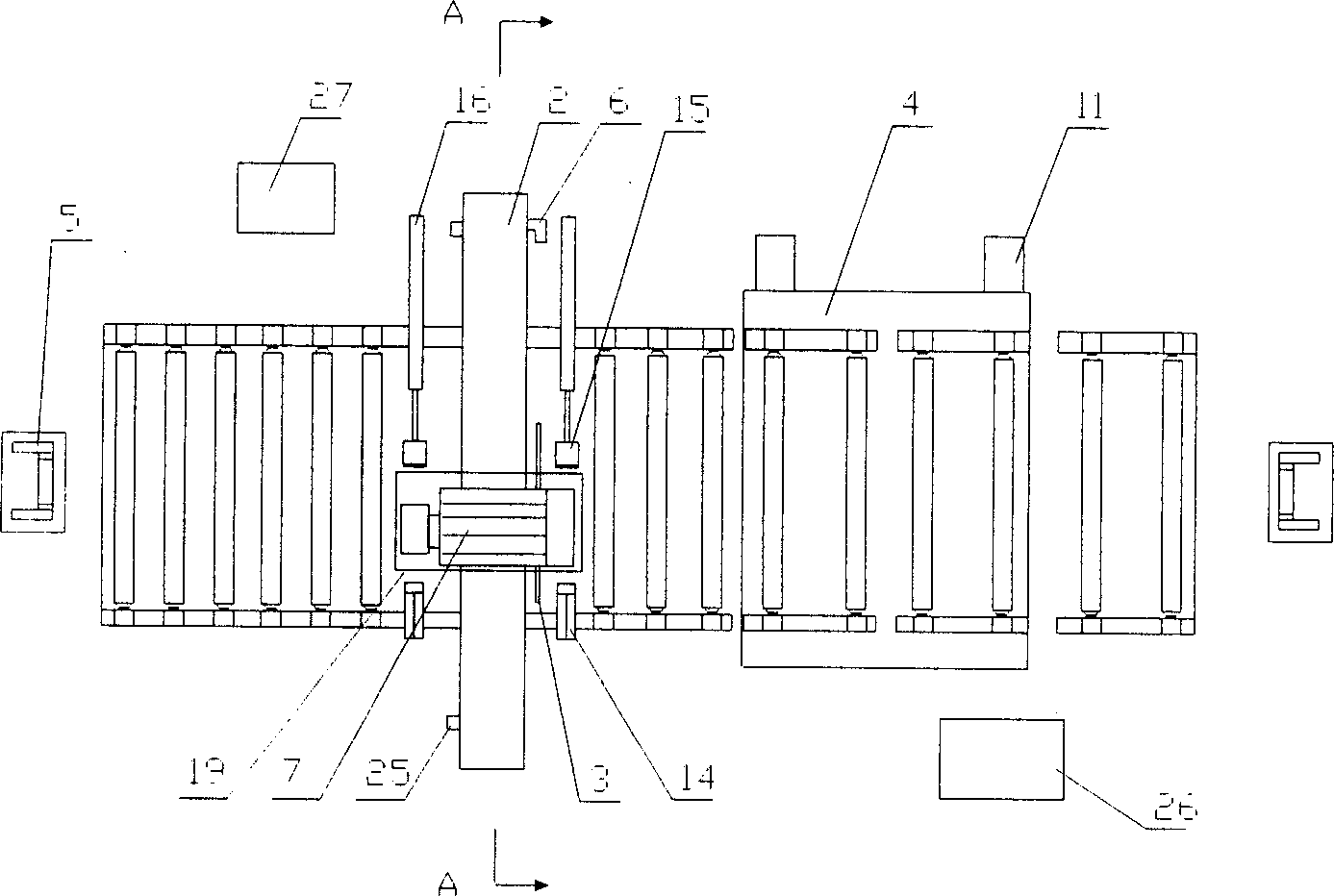

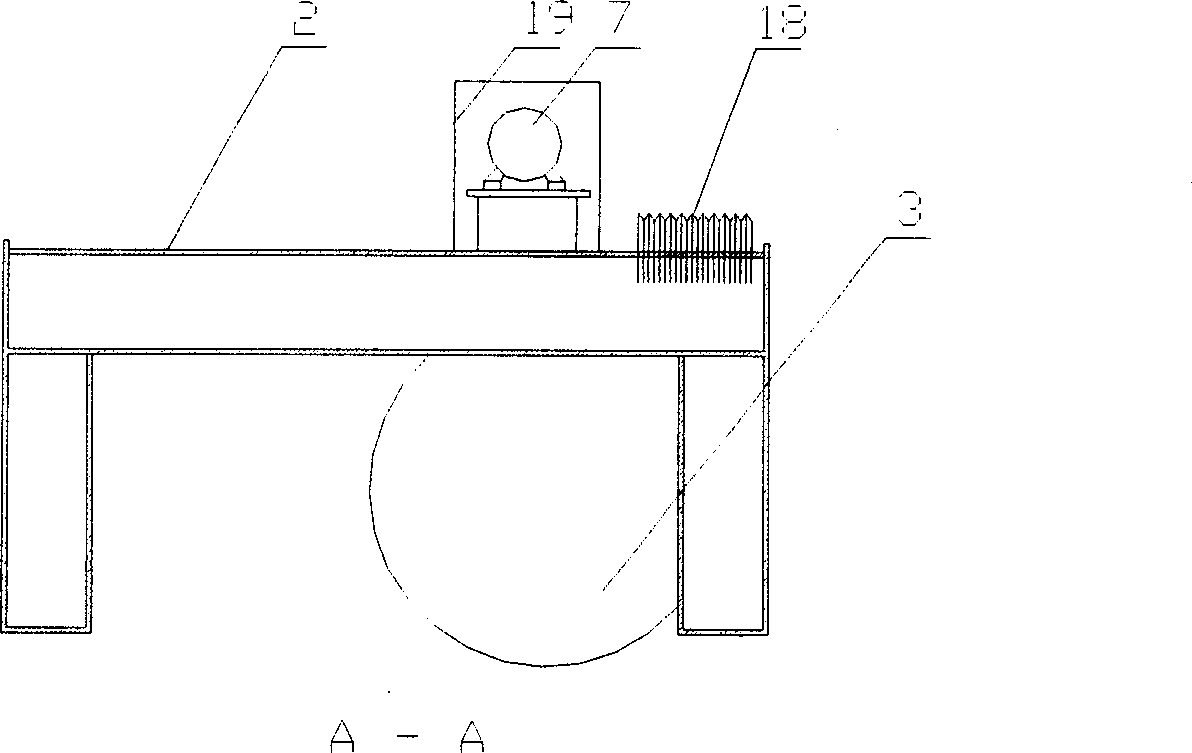

[0022] Embodiments of the present invention: as attached Figure 1-5 As shown, a conveying roller table is installed on the frame (1), and a sawing clamping mechanism (8) and a gantry are arranged at the junction of the sawing conveying section (9) and the sawing conveying section (10) of the conveying roller table. type frame (2), set travel box (19) and screw mandrel feed system on the gantry frame (2), travel box (19) links to each other with electric control system (27), and electric control system (27) consists of The main control cabinet, step-down starting cabinet, and manual control box are composed of three parts, and are controlled by PLC. Connect the traveling box (19) with the screw feed system, install the motor (7) and the main shaft (17) in the traveling box (19), install the circular saw disc (3) on one end of the main shaft (17) , connect the other end of the main shaft (17) to the power output shaft of the motor (7), and connect the circular saw disc (3) to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com