Steering device for motor vehicle

A steering device and vehicle technology, applied in the steering column, steering control mounted on the vehicle, steering control, etc., can solve the problems of high surface pressure, uncontrollable lag amplitude, and the steering shaft cannot meet the torque transmission performance and life. , to achieve the effect of stable sliding load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

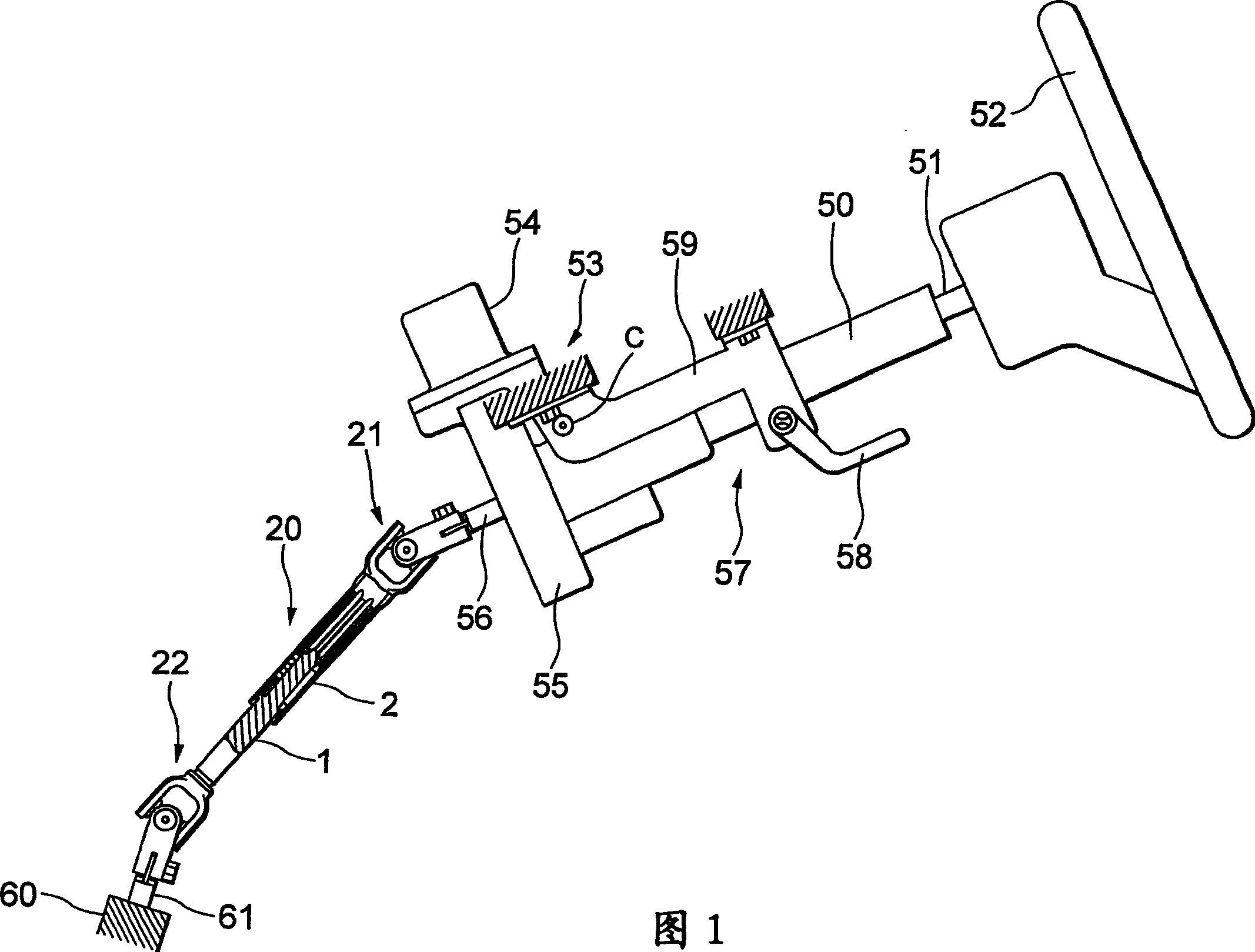

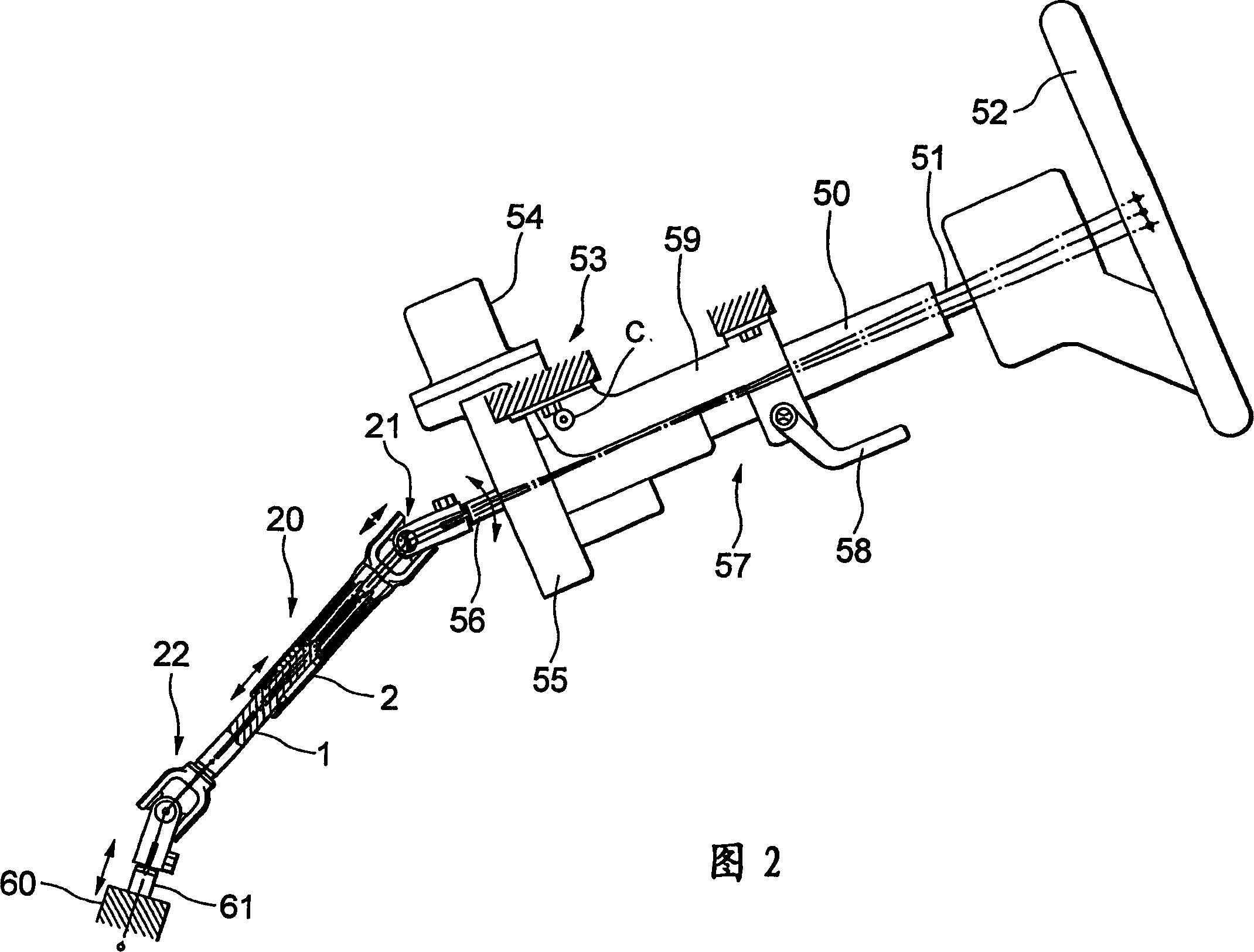

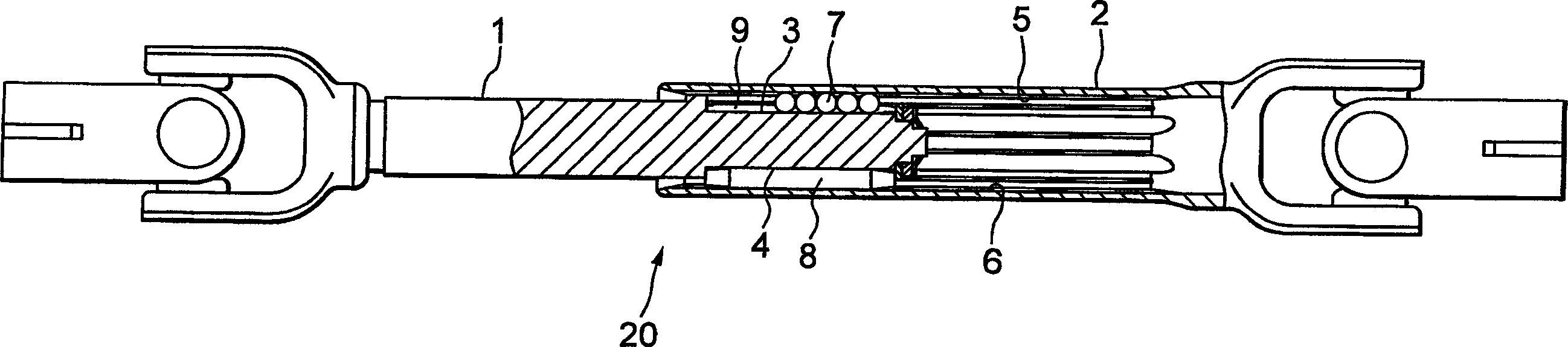

[0066] 1 is a schematic diagram of a steering device for a vehicle according to a first embodiment of the present invention, and FIG. 2 is a schematic diagram of the steering device for a vehicle shown in FIG. 1, showing the highest and lowest degrees of inclination, and for explaining various axes. to the displacement.

[0067] The steering shaft 51 is rotatably supported on the steering column 50 , and a steering wheel 52 is provided on the upper portion of the steering shaft 51 .

[0068] The steering column 50 is provided with a column-assisted electric steering device 53, and the column-assisted electric steering device 53 is provided with a motor 54 for assisting power, a gear set 55 used as a reducer, and a gear set 55 used for high-speed rotation. An output shaft 56 that outputs the steering force assisted by the electric motor 54 and the like.

[0069] A tilt mechanism 57 is also provided on the steering column 50 . When the operation lever 58 is operated, the steer...

no. 2 example

[0125] 6 is a schematic diagram of a steering device for a vehicle according to a second embodiment of the present invention. Fig. 7 is a schematic diagram of the steering device for a vehicle shown in Fig. 6, showing its telescoping and sliding state. FIG. 8 is a view showing only the center line of FIG. 7 in a state where the intermediate shaft is extended or shortened by telescopic sliding.

[0126] The second embodiment has a columnar structure that has a telescoping function in addition to the tilting function, so that the entire steering column 50 can move in the axial direction. In this case, the intermediate shaft 20 needs to be able to expand and contract freely.

[0127] As shown in Figure 6, a long hole 31 for telescopic operation is formed on the bracket 59 fixed on the vehicle body side, and another long hole for telescopic operation is formed on the support bracket 32 arranged on the steering column 50. 33.

[0128] As shown in FIG. 7 , the position of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com