Light-emitting diode and its manufacturing method

A technology of light emitting diode and manufacturing method, applied in the field of lighting, can solve the problems of poor electrical and thermal conductivity of sapphire substrate, current concentration effect, small contact area and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

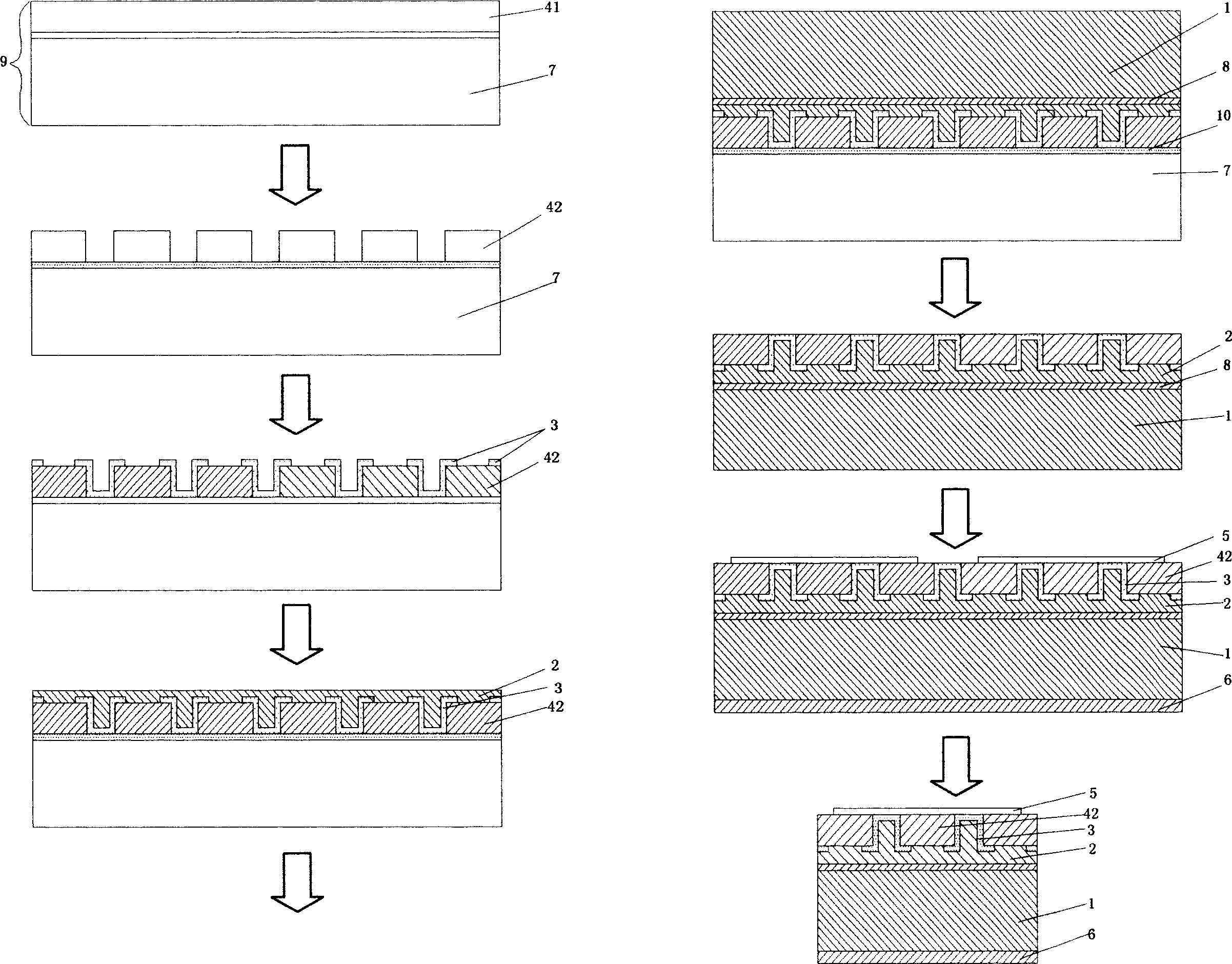

[0021] The present invention will be further described below in conjunction with accompanying drawing.

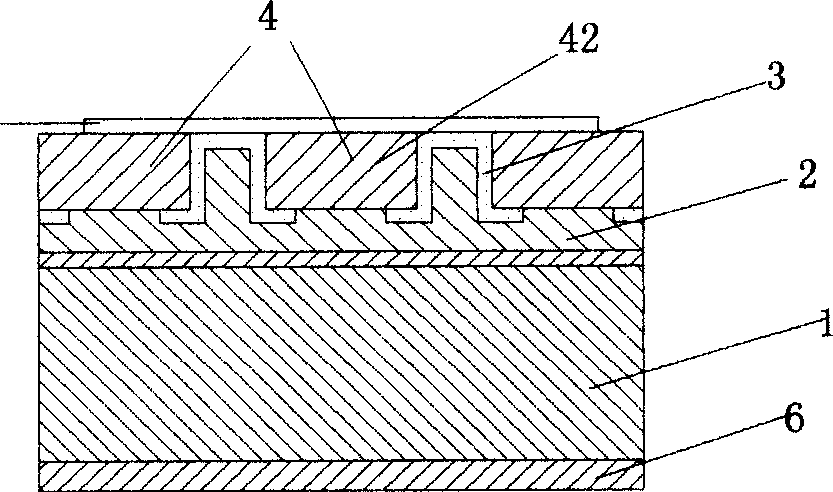

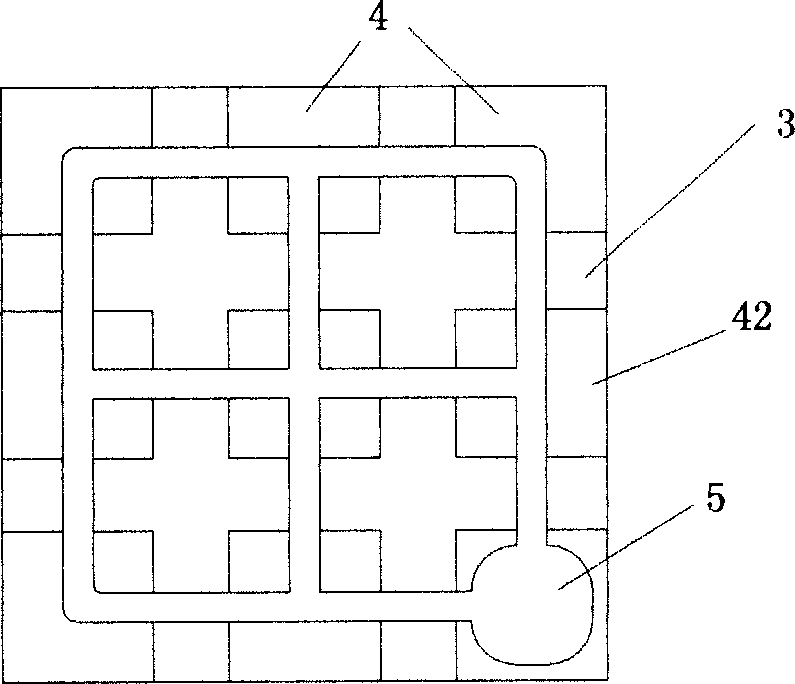

[0022] attached figure 1 with 2 In the light-emitting diode of the illustrated embodiment, the substrate 1 is a P-type contact electrode 2 composed of three metal layers of gold, nickel, and gold, and the P-type contact electrode 2 has light-emitting single packets 42 arranged in a matrix. A reflective insulating film 3 formed by interlaced lamination of silicon dioxide layers and silicon nitride layers is provided between the single packages 42 (the reflective insulating film 3 not only has the function of isolating adjacent light-emitting single packages 42, but also has the function of reflecting light out to improve the light output rate), the reflective insulating film 3 stretches between the P-type contact electrode 2 and the light-emitting single package 42, and forms a surrounding around the contact surface of the light-emitting single package 42 and the P-type con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com