Optical acceleration sensor based on Fresnel diffraction micr-lens

An acceleration sensor, Fresnel diffraction technology, applied in the direction of acceleration measurement using inertial force, navigation through speed/acceleration measurement, etc., can solve problems such as complex processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

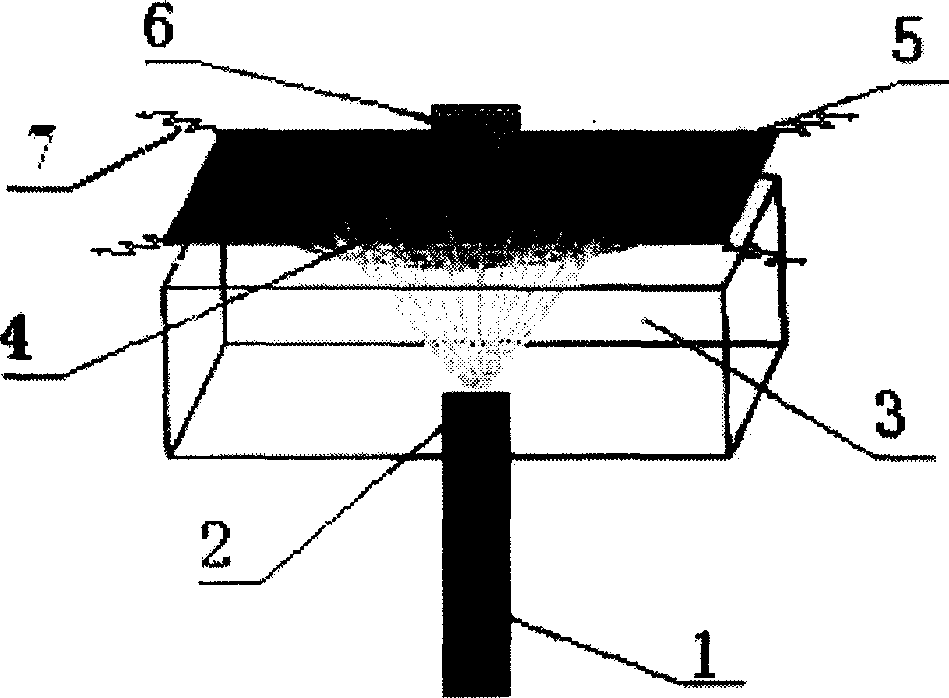

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the main components of the optical acceleration sensor based on the Fresnel diffraction microlens of the present invention are: optical fiber 1, optical fiber end 2 (the optical fiber end 2 is the end of optical fiber 1), glass substrate 3, Fresnel Ear diffraction micro-lens 4, micro-reflective film 5, micro-mass 6, micro-spring 7, frame 8 for fixing spring, shell (not shown in the figure).

[0020] Such as figure 1 As shown, a Fresnel diffraction microlens 4 is processed on the surface of the glass substrate 3 by microfabrication techniques such as sputtering, photolithography, and corrosion, and the odd (or even) half-band of the Fresnel diffraction microlens 4 is plated The last layer of reflective metal film, the even (or odd) bands keep the transparency of the glass; the microreflective film 5 is placed in parallel with the Fresnel diffraction microlens 4 and keeps a small distance (several wavelengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com