Concrete-bar straightening cutting machine

A cutting machine and steel bar technology, applied in the field of steel bar straightening and cutting machine, can solve the problems of steel bar raw material waste, high labor intensity of workers, low production efficiency, etc., achieve high automation control, reduce labor intensity, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

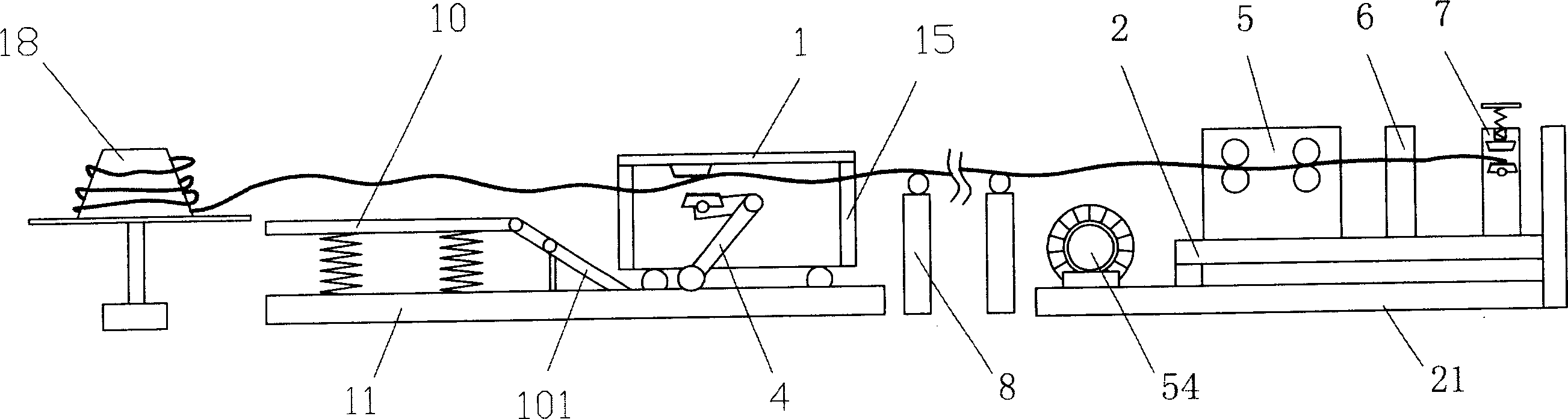

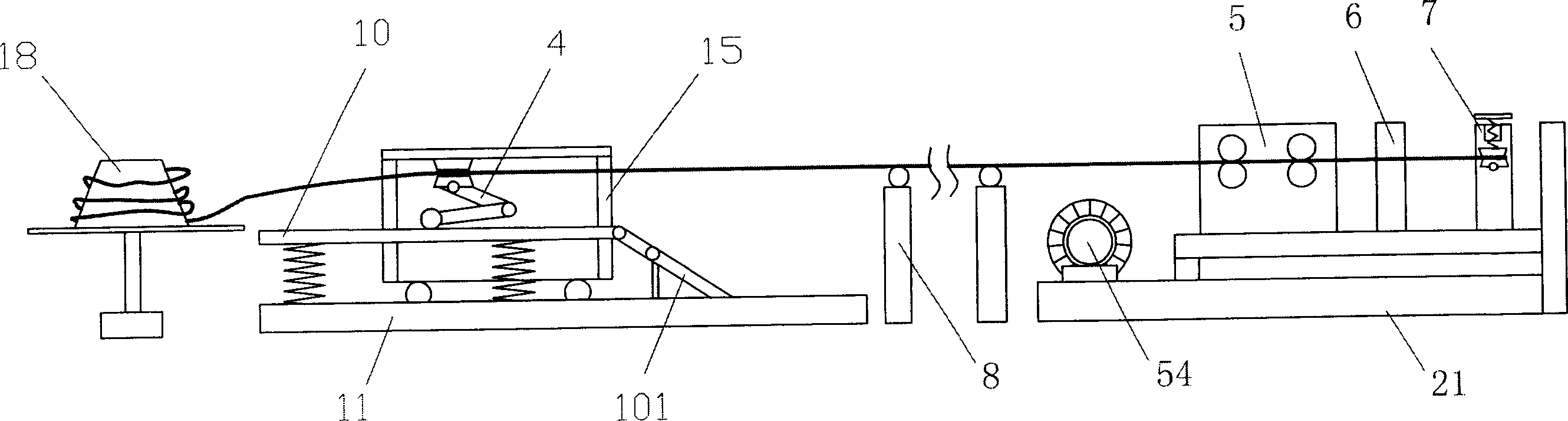

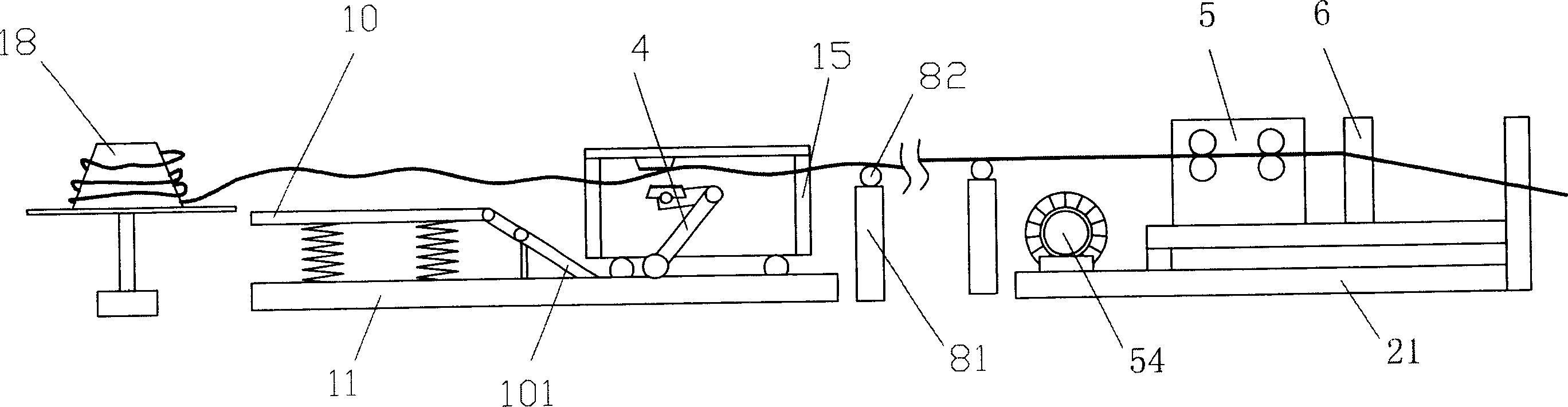

[0024] refer to Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , a steel bar straightening and cutting machine, including a feeding device 18 for placing a disc-shaped steel bar, a reciprocating automatic clamping and straightening mechanism 1, a feeding, cutting, and locking device 2, and a feeding device 18 used in this product It is a turntable, and the reciprocating automatic clamping and straightening mechanism 1 includes a base 11 fixed on the ground. The base 11 is provided with a guide device 10 with an inclined guide bridge 101. The base 11 is provided with a guide groove, and the guide A mobile frame 15 driven by a power unit 14 is provided on the groove, and an upper tooth plate 12 and a rocker arm assembly 4 that can move along the guide device 10 are installed above the frame 15. The rocker arm assembly 4 Including the curved rod 41 whose middle part is hinged on the vehicle frame 15, the two ends of the curved rod 41 are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com