Fast polybrominated biphenyl ether degrading method with nanometer iron powder

A polybrominated diphenyl ether and nano iron powder technology, which is applied in the direction of protection devices against harmful chemical agents and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

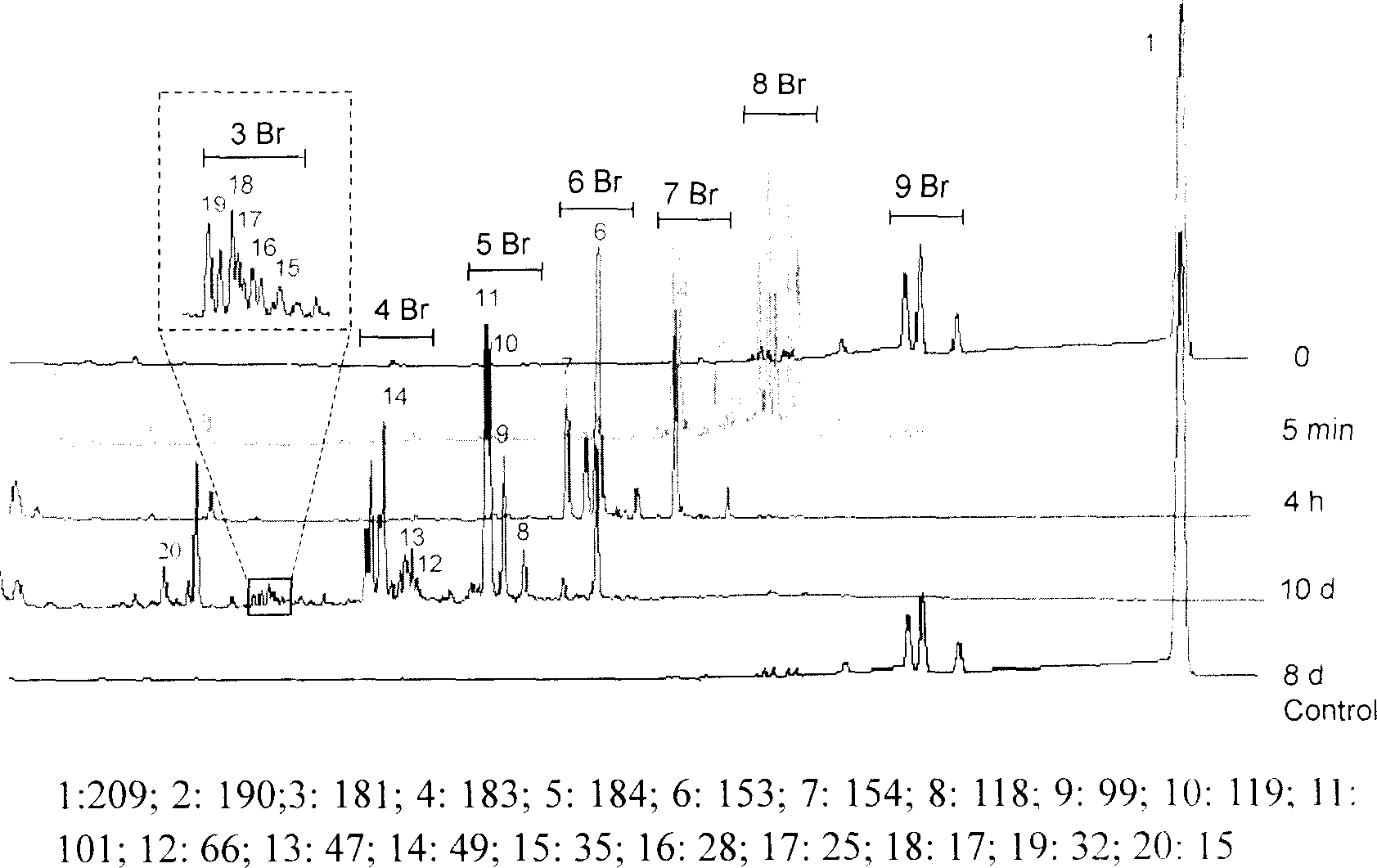

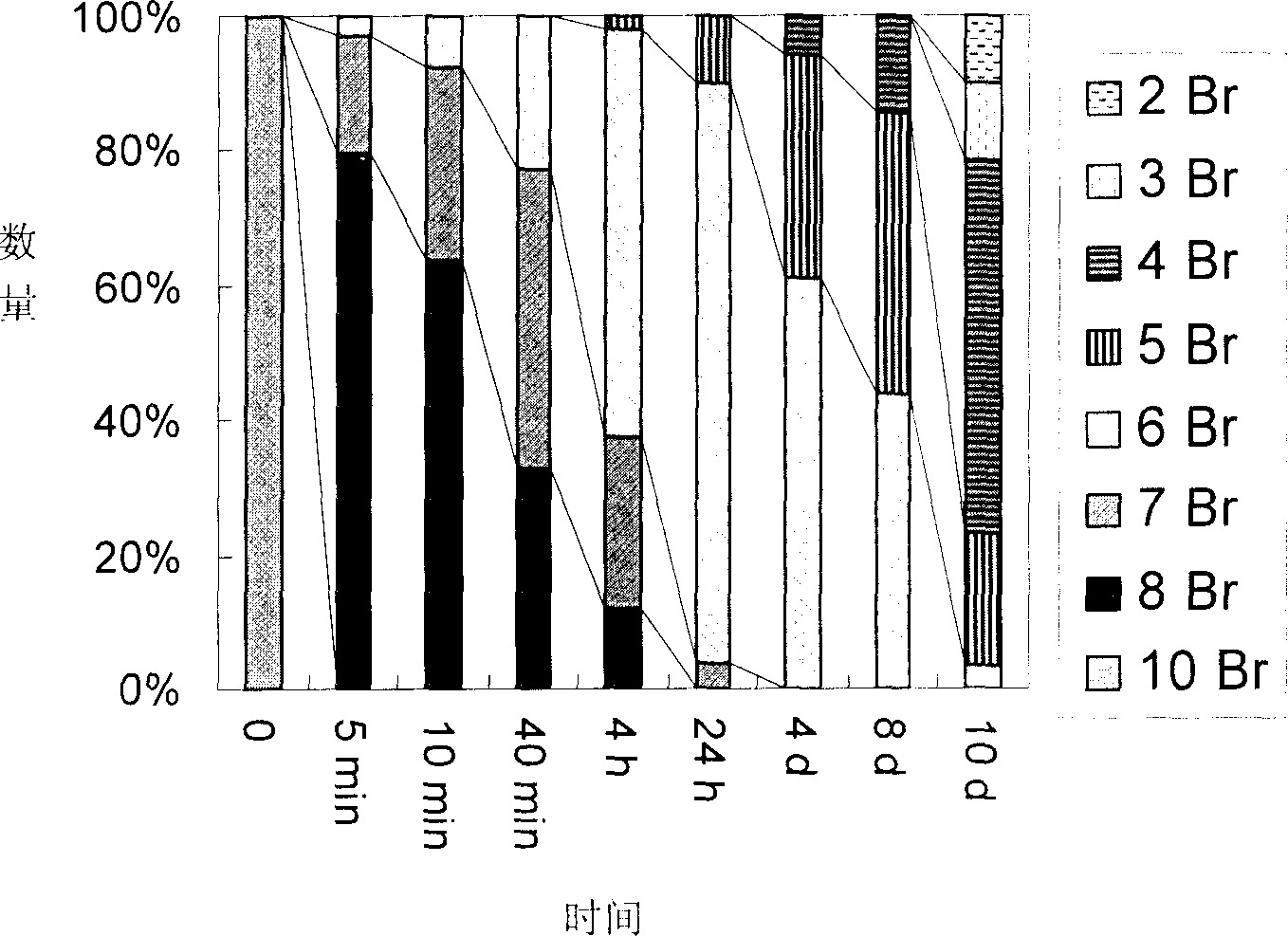

[0018] The nano-iron powder used in the present invention is purchased from Japan Toda Kogyo Corp., and its transmission electron microscope photo is as follows figure 1 shown. The particle size distribution of most particles is between 10 and 50nm, with a diameter of 31.8m 2 / g specific surface area. Decabromodiphenyl ether was used as the initial degradation object, and a 5 mL stoppered glass tube was used as the reaction vessel. The initial concentration of BDE209 was 0.5μg / ml, the concentration of nano-iron powder was 0.125g / ml, and the degradation experiment was carried out under the conditions of normal temperature and pressure and dark conditions. Within the specified time, take three parallel reaction glass tubes and slowly add 1ml of concentrated hydrochloric acid to remove iron powder. The resulting solution is extracted three times with 0.5ml of toluene, and the combined extracts are determined by GC-ECD. The degradation products of different BDE209 were identifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com