Method for bonding nanometer material on metal electrode

A technology of metal electrodes and nanomaterials, applied in the field of nanometers, can solve problems such as inability to simplify and batch, incompatibility with IC technology, and incompatibility with IC technology, and achieve low cost, firm and reliable contact, and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

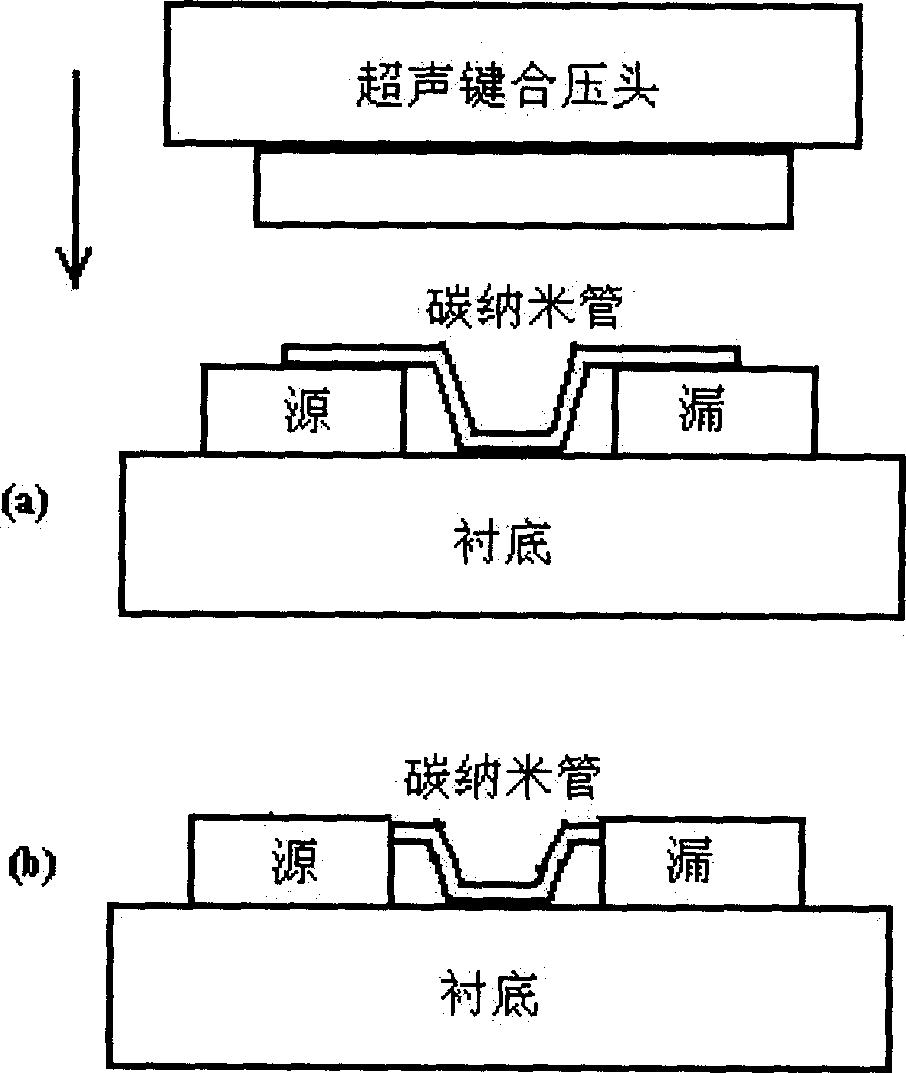

[0017] A single carbon nanotube bundle is connected between the Au electrodes on the chip, so that the end of the carbon nanotube rests on the surface of the electrode. Using a wire bonder, ultrasonically bond the contacts. The ultrasonic power is 10W, the ultrasonic time is 500ms, the extrusion pressure is 0.01N, the bonding head is preheated to 400 degrees, and the chip is preheated to 300 degrees. At the end, the carbon nanotubes are welded together with the metal electrodes. Before ultrasonic bonding, carbon nanotube bundles remain on the electrode surface, but after ultrasonic bonding, it can be found that carbon nanotubes and electrodes are welded together, almost no CNT can be seen on the electrode surface, and CNT is embedded in the electrode. Finally, the i-v curves before and after pressure welding were measured with a precision semiconductor parameter tester. The results showed that the two-terminal resistance dropped by 3-4 orders of magnitude, from 55MΩ before pr...

Embodiment 2

[0019] A single Si nanowire is connected between the Al electrodes on the chip, so that the end of the carbon nanotube rests on the upper surface of the electrode. The contacts are ultrasonically bonded using a wire bonder. The ultrasonic power is 30W, the ultrasonic time is 1ms, the extrusion pressure is 2.5N, the bonding head is not preheated, and the chip is not preheated. Since the bonding part of the bonding head covers the end of the carbon nanotube in contact with the electrode, the carbon nanotube The tubes are welded together with metal electrodes. The Si nanowires on the electrode after ultrasonic bonding and the electrode are welded together. The Si nanowires are almost invisible on the surface of the electrode. The Si nanowires are embedded in the electrode, forming a firm and reliable contact, and the two-terminal resistance is reduced by 3 -4 orders of magnitude.

Embodiment 3

[0021] A plurality of SiC nano whiskers are connected between the SiAl electrodes on the chip, so that the ends of the carbon nanotubes are pressed on the lower surface of the electrodes. The contacts are ultrasonically bonded using a wire bonder. The ultrasonic power is 0W, the ultrasonic time is 1000ms, the extrusion pressure is 1N, the bonding head is preheated to 200 degrees, and the chip is preheated to 150 degrees. After the SIC nano whiskers on the two electrodes are ultrasonically bonded, they form a firm and reliable contact with the electrodes, and the two-terminal resistance drops by 3-4 orders of magnitude.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com