Composite window

A composite window and polymer material technology, applied in the field of composite windows, can solve the problems of inability to effectively ensure watertight performance, sound insulation, poor thermal insulation, affecting wind pressure resistance, etc., and achieve simple structure, good thermal insulation, and wind resistance. Strong pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with accompanying drawing:

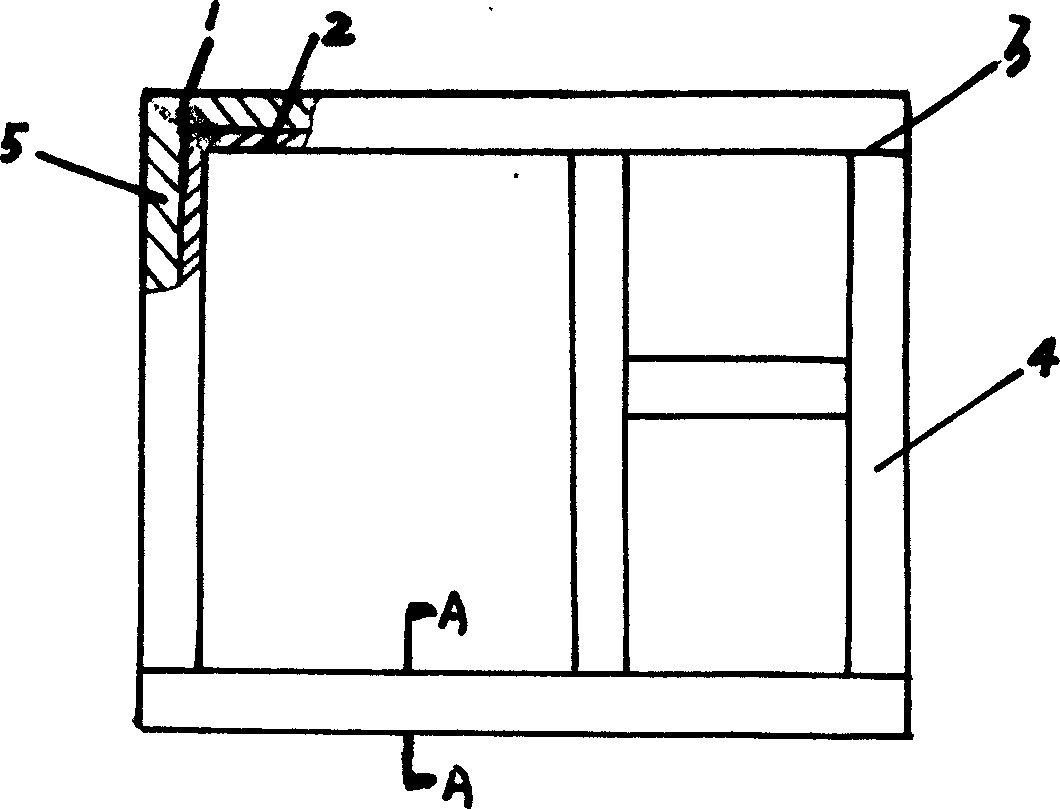

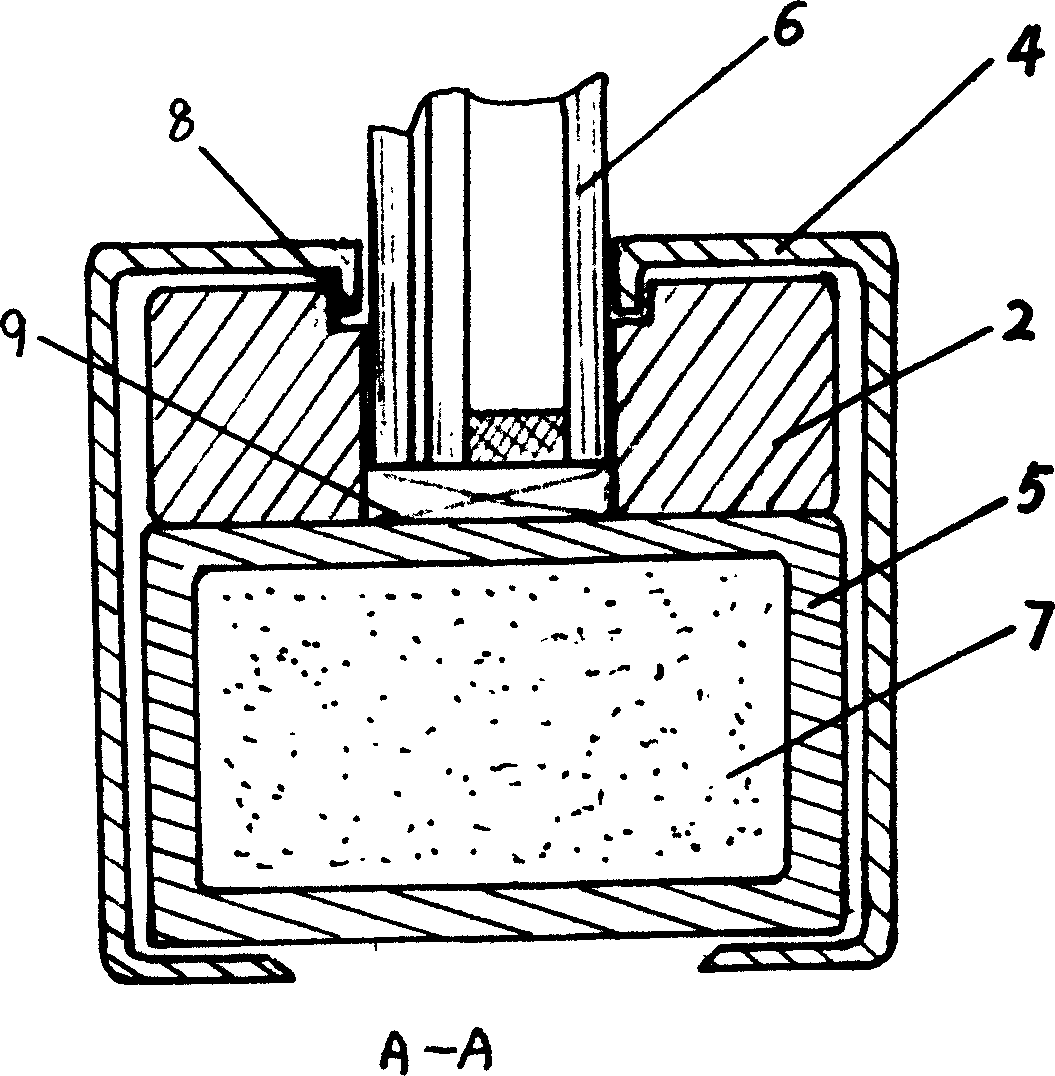

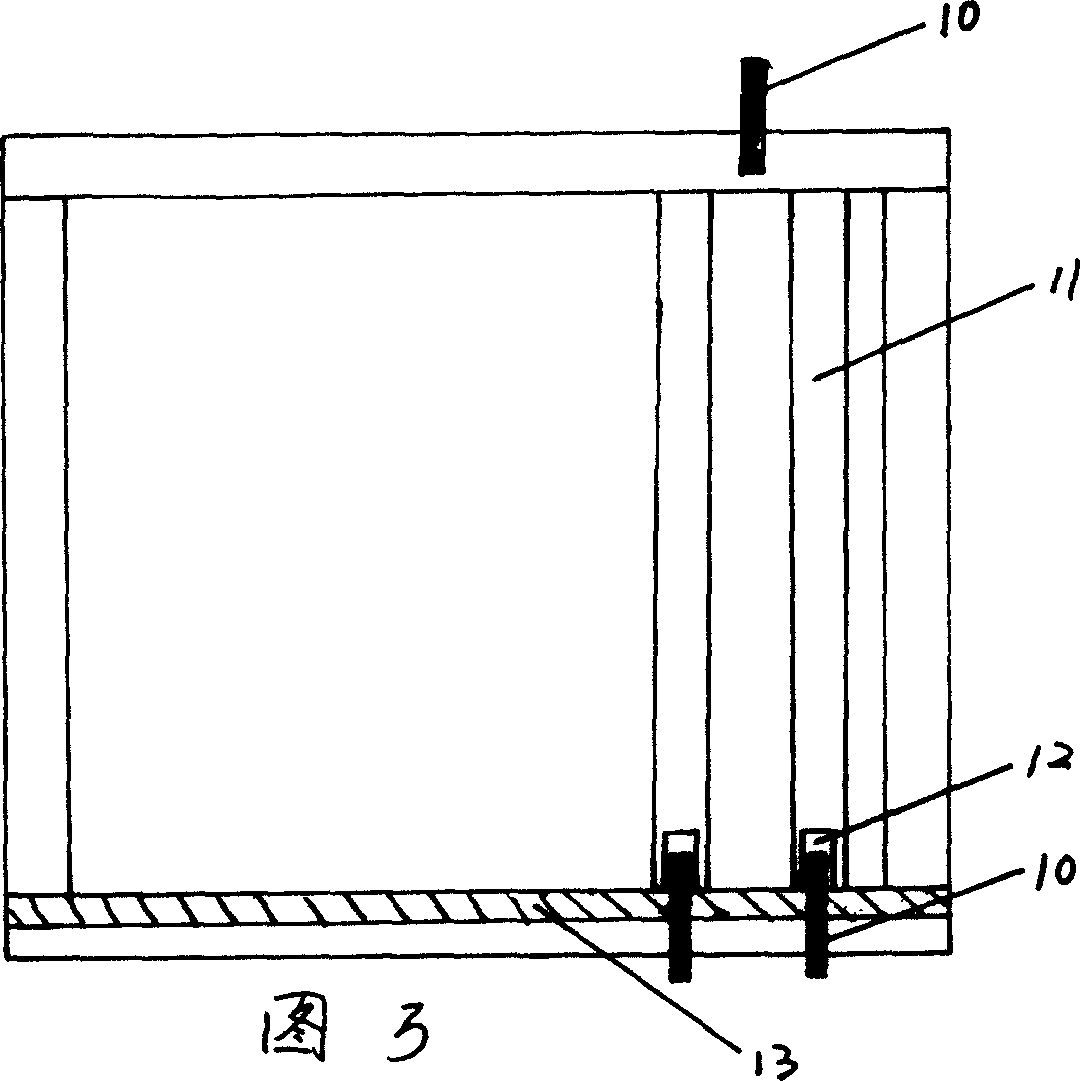

[0013] The composite window is mainly composed of aluminum profile 4, PVC bead 2, steel pipe 5, and laminated multi-layer glass 6. Two PVC bead 2 are respectively fixed on one side of the square steel pipe 5, and the space between the PVC bead 2 and the steel pipe 5 is self-tapping The screw is fixed, the laminated multi-layer glass 6 is sandwiched between two PVC bead 2, and the upper corner of the PVC bead 2 and the glass 5 has a buckle groove 8, which can be conveniently clamped on the aluminum profile 4 and is waterproof , anti-theft, beautiful effect. The aluminum profile 4 is stuck on both sides of the PVC bead 2 and the outer surface of the steel pipe 5 . The aluminum profile 4 is bonded 3 at a flat angle at the corner of the window, and the steel structure 5 is formed by welding 1 at a 90° flat angle with the aluminum profile 4 bonding 3 at the corner of the window...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com