Method for producing air permeable embossing wheel

A manufacturing method and breathable pressure technology, which is applied in the manufacture of tools, textile decoration, textiles and papermaking, etc., can solve the problems of no space for gas to dissipate, loss of cost and time course, and no air permeability, etc., to achieve the promotion effect and economy Benefits, improving the phenomenon of softness and hardness, and increasing the stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

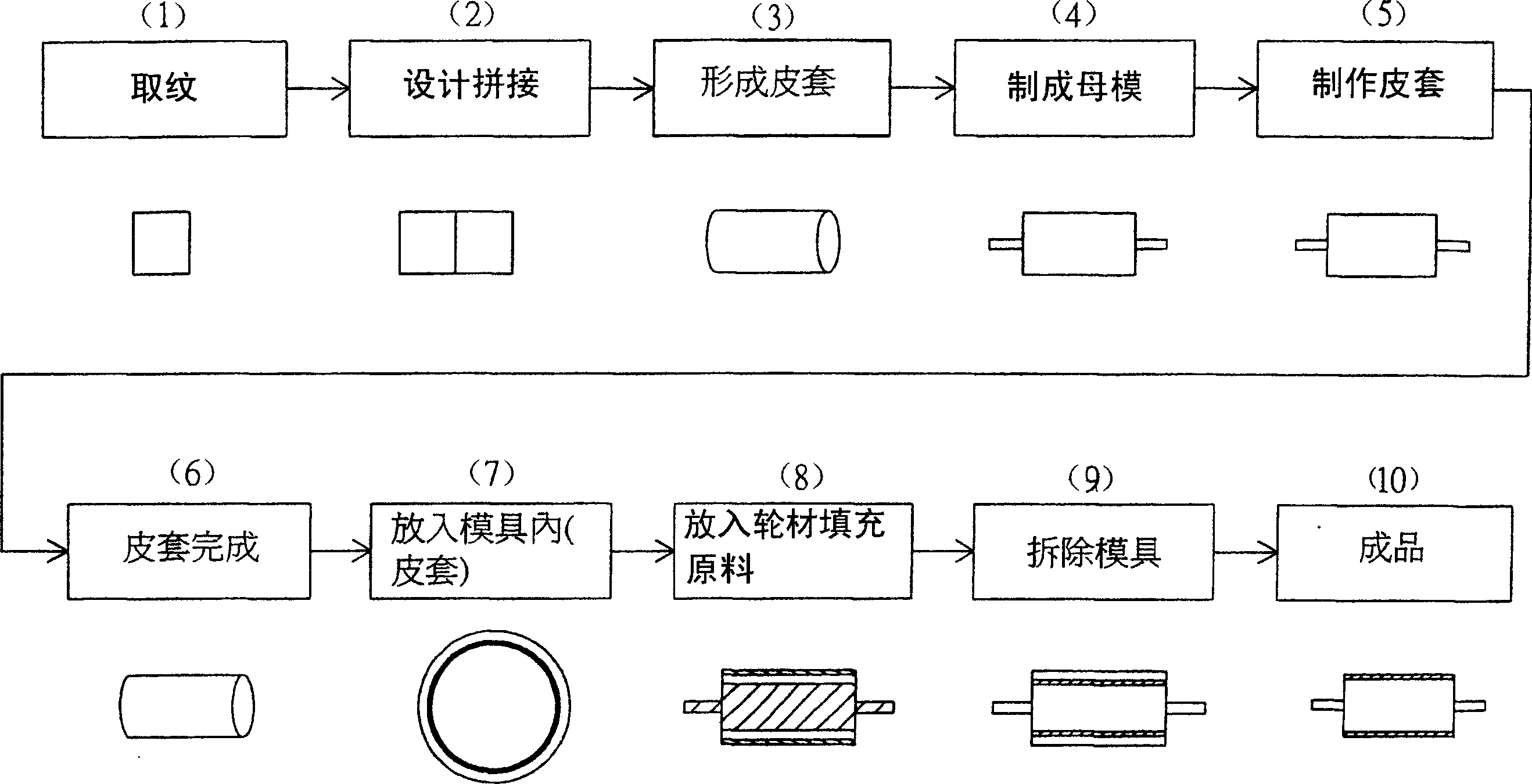

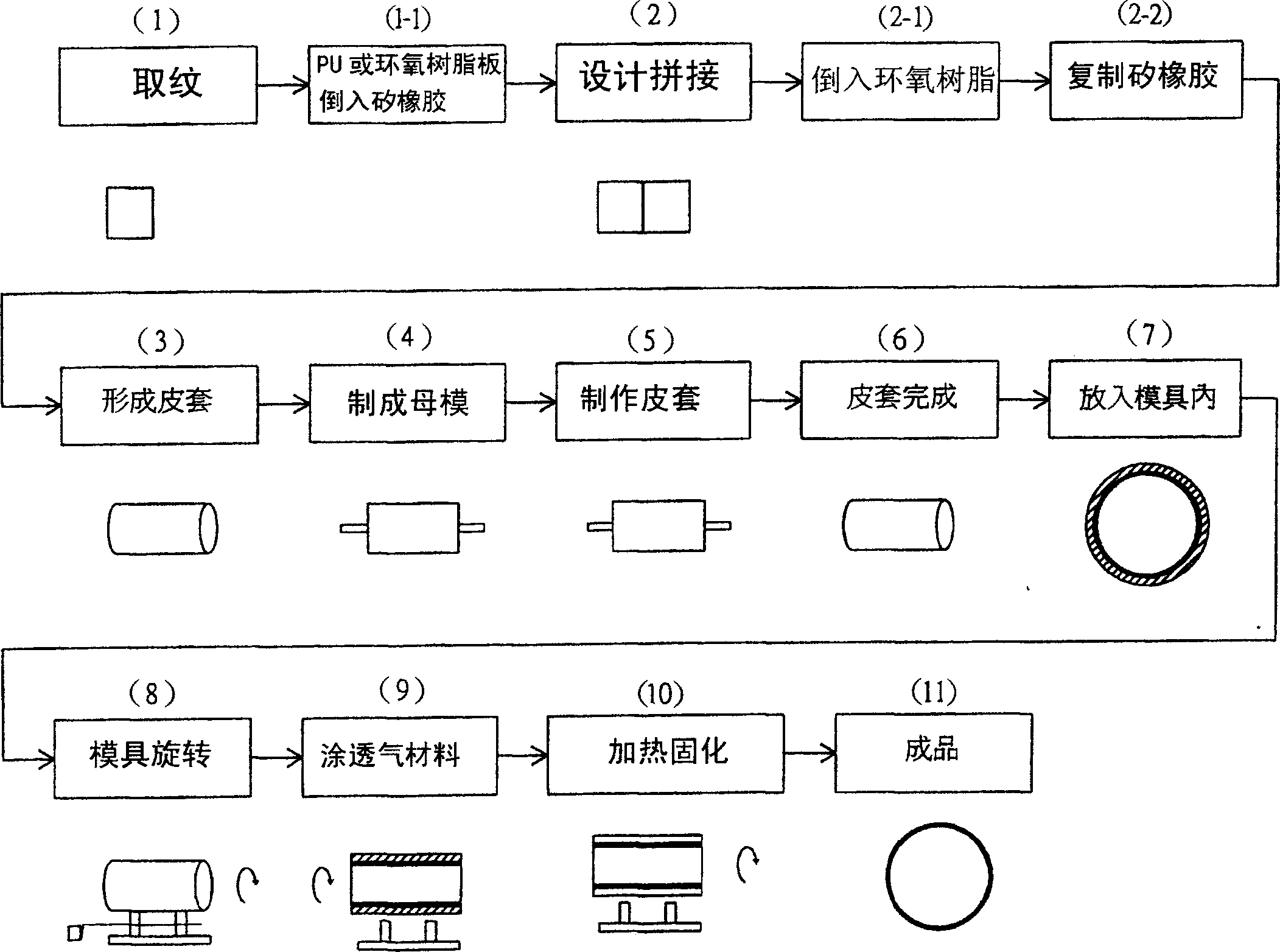

[0022] Breathable embossing wheel shown in the present invention, its manufacturing process, as figure 2 shown, including the following steps:

[0023] (1) Texture of the original: use PU, silicone or epoxy resin to take the texture of the original, and the texture is mainly letterpress design;

[0024] (1-1) Form relief: pour silica gel on PU, silica gel or epoxy resin board to form a relief pattern;

[0025] (2) Design splicing: splicing the selected letterpress pattern according to the order of the scheduled discharge position;

[0026] (2-1) Form gravure: on the relief pattern, pour epoxy resin to form gravure;

[0027] (2-2) Replication of silica gel: add silica gel to the gravure made of previous epoxy resin;

[0028] (3) Forming the leather case: After copying the silicone leather case, the original spliced original pattern is reprinted on the silicone case, so the silicone case is still the original letterpress;

[0029] (4) Make a master mold: Put the prepared ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com