Reinforced smoke discharging mode in aluminum cell opening operation

A technology of aluminum electrolytic cells and smoke exhaust pipes, which is applied in the field of strengthening the smoke exhaust method when the aluminum electrolytic cell is opened, can solve the problems of the limitation of the gas collection efficiency of the electrolytic cell, the high emission of pollutants, and the unsatisfactory effect, etc., to achieve Good smoke exhaust effect, simple structure and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

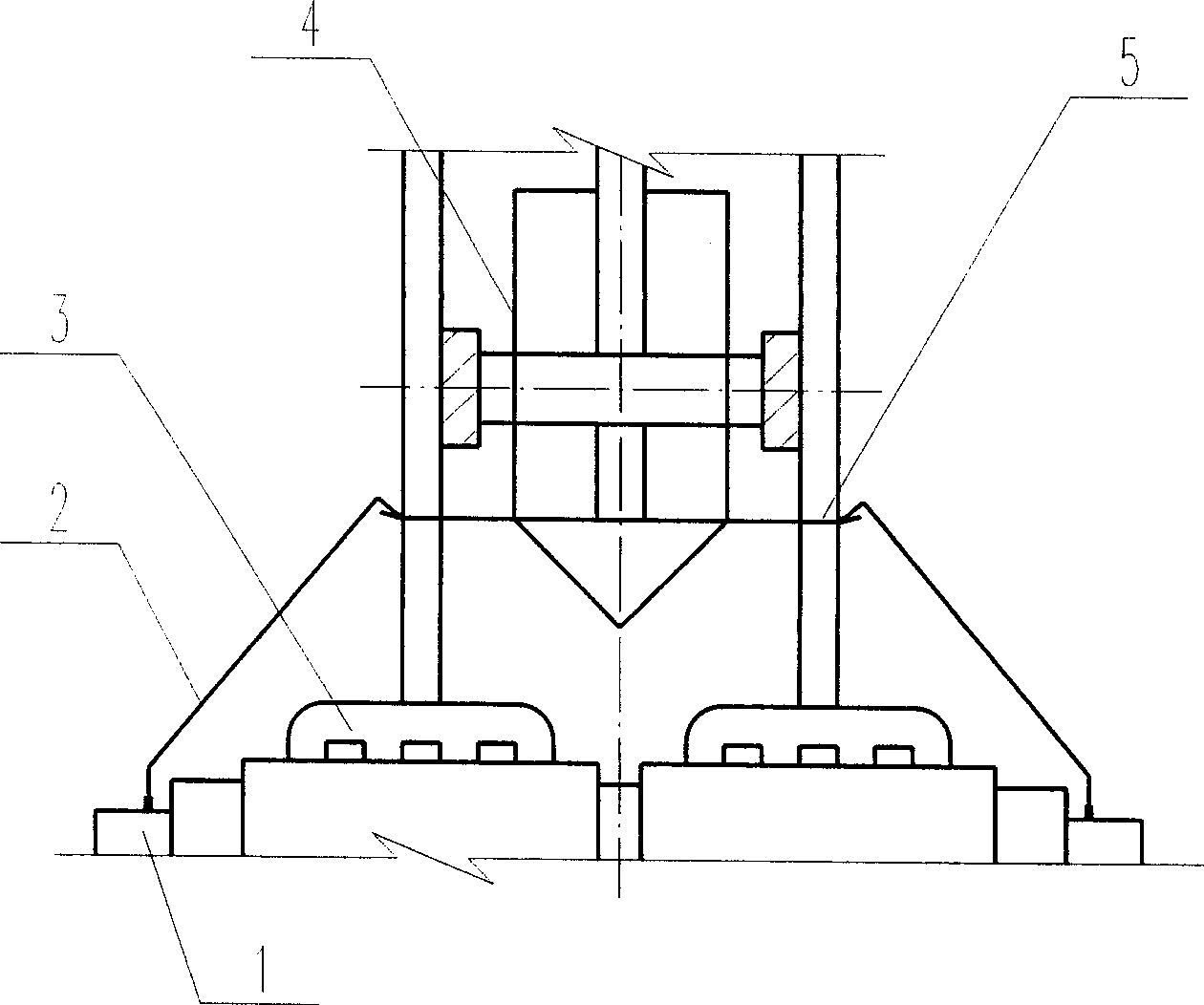

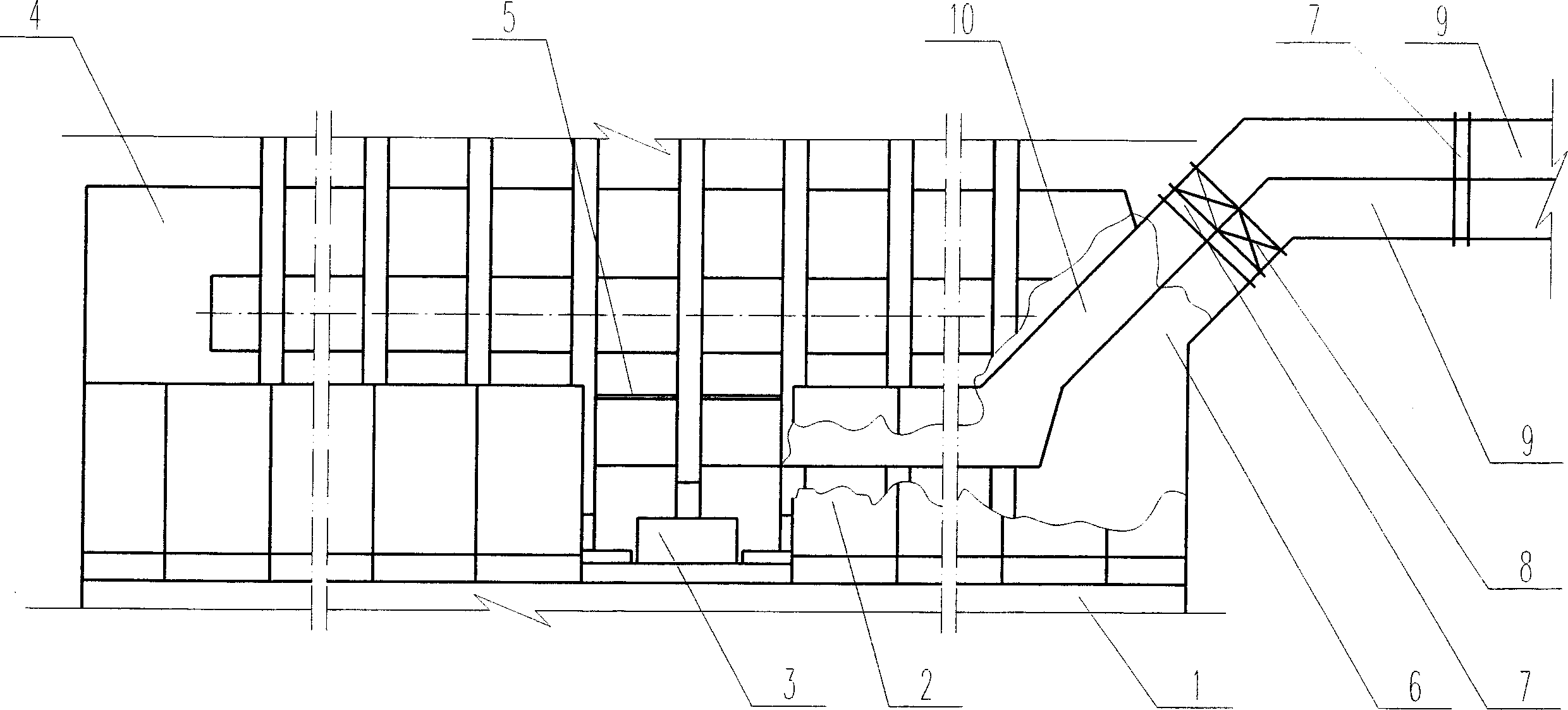

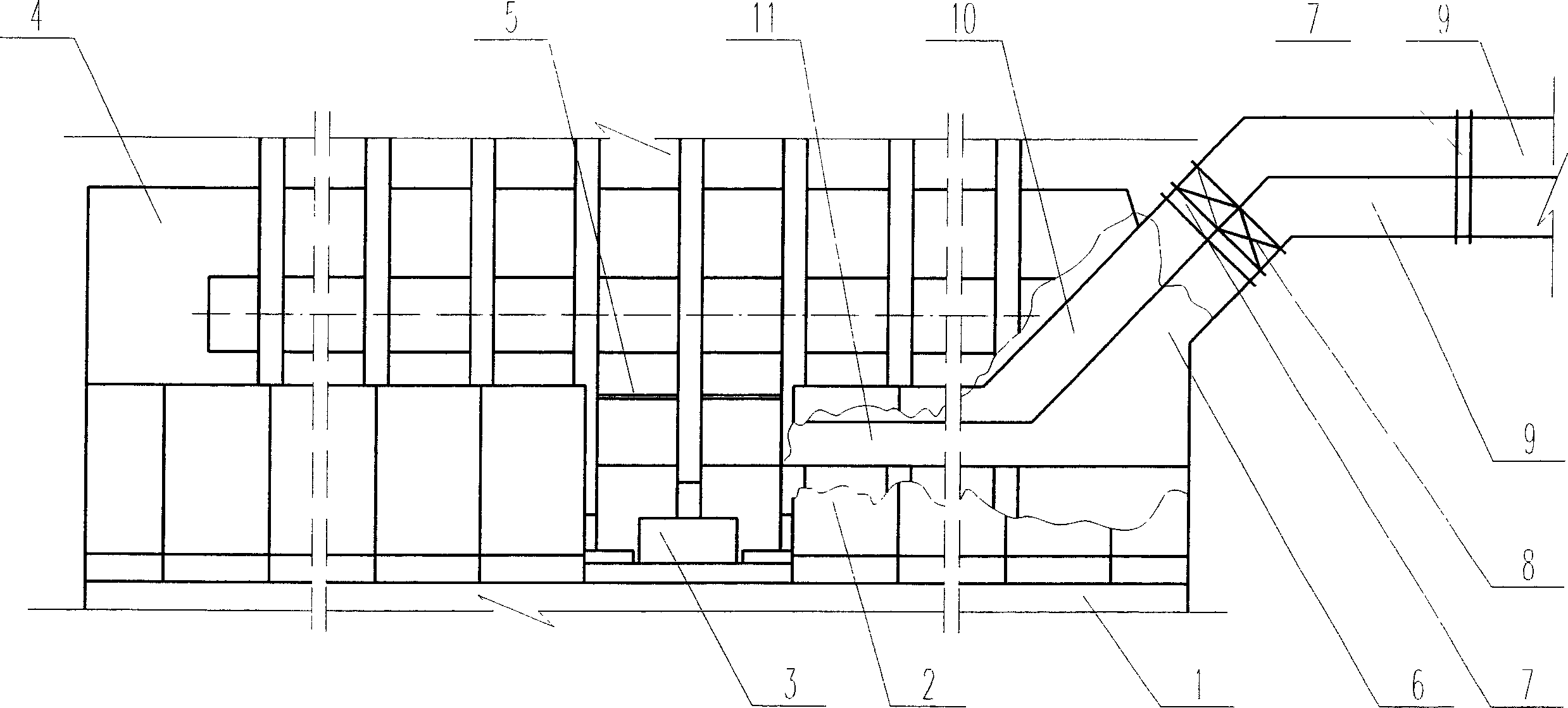

[0020] The implementation of the present invention is very easy. Utilize the usual airtight structure of the electrolytic cell, namely, the cell chamber upper space surrounded by the cell shell 1 and the cathode top cover material surface, the horizontal cover plate 5 and both sides and the end sealing cover 2 is the implementation cell Side-suction plenum. The suction pipe connection port 6 can be connected at any position that does not affect the operation, at the end, on the groove superstructure, in single-point or multi-point or strip-shaped, etc. modes. The air is directly exhausted to the upper space of the tank chamber, and this structure exhausts the air from the opening of the sealing cover in the form of air suction at the side of the tank, so as to control the emission of pollutants and improve the gas collection efficiency of the electrolytic cell.

[0021] Although the suction pipe connection port 6 adopts the multi-point or strip access method, which is more com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com