Radiant pad for display device, backlight assembly and flat panel display device having the same

A backlight component and display technology, applied in optics, light sources, instruments, etc., can solve problems such as internal temperature rise, internal temperature unevenness, and liquid crystal display display quality decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, exemplary embodiments of the present invention are explained in detail with reference to the accompanying drawings.

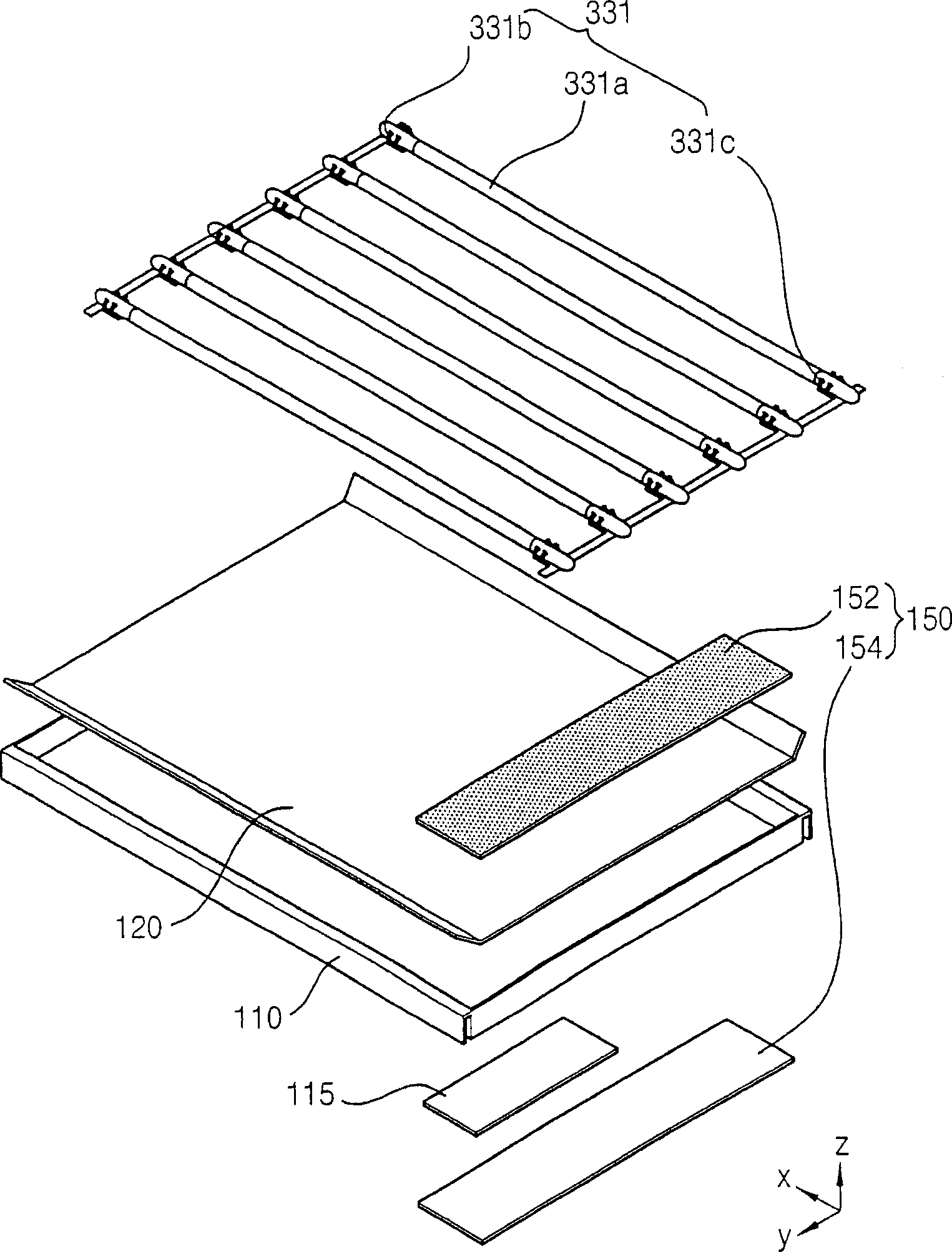

[0028] figure 1 is an exploded perspective view showing a backlight assembly according to an exemplary embodiment of the present invention;

[0029] refer to figure 1 , the backlight assembly 100 includes a bottom frame 110 , a reflective plate 120 , a lamp 130 , a lamp guide and a radiation spacer 150 .

[0030] The bottom frame 110 has a bottom plate and side walls extending from the bottom plate to provide a receiving space. Accordingly, the bottom frame 110 is a receiving container for receiving the lamp 130 and the reflective plate 120 . An inverter 115 is disposed on a surface of the bottom plate of the bottom frame 110 opposite to the reflection plate 120 . In other words, the inverter 115 is disposed on the outer surface of the bottom frame 110 .

[0031] The reflective plate 120 is disposed in the accommodation space of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com