Pneumatic tire

A pneumatic tire and tire technology, applied in the field of tread patterns, can solve problems such as easy increase in grip and instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

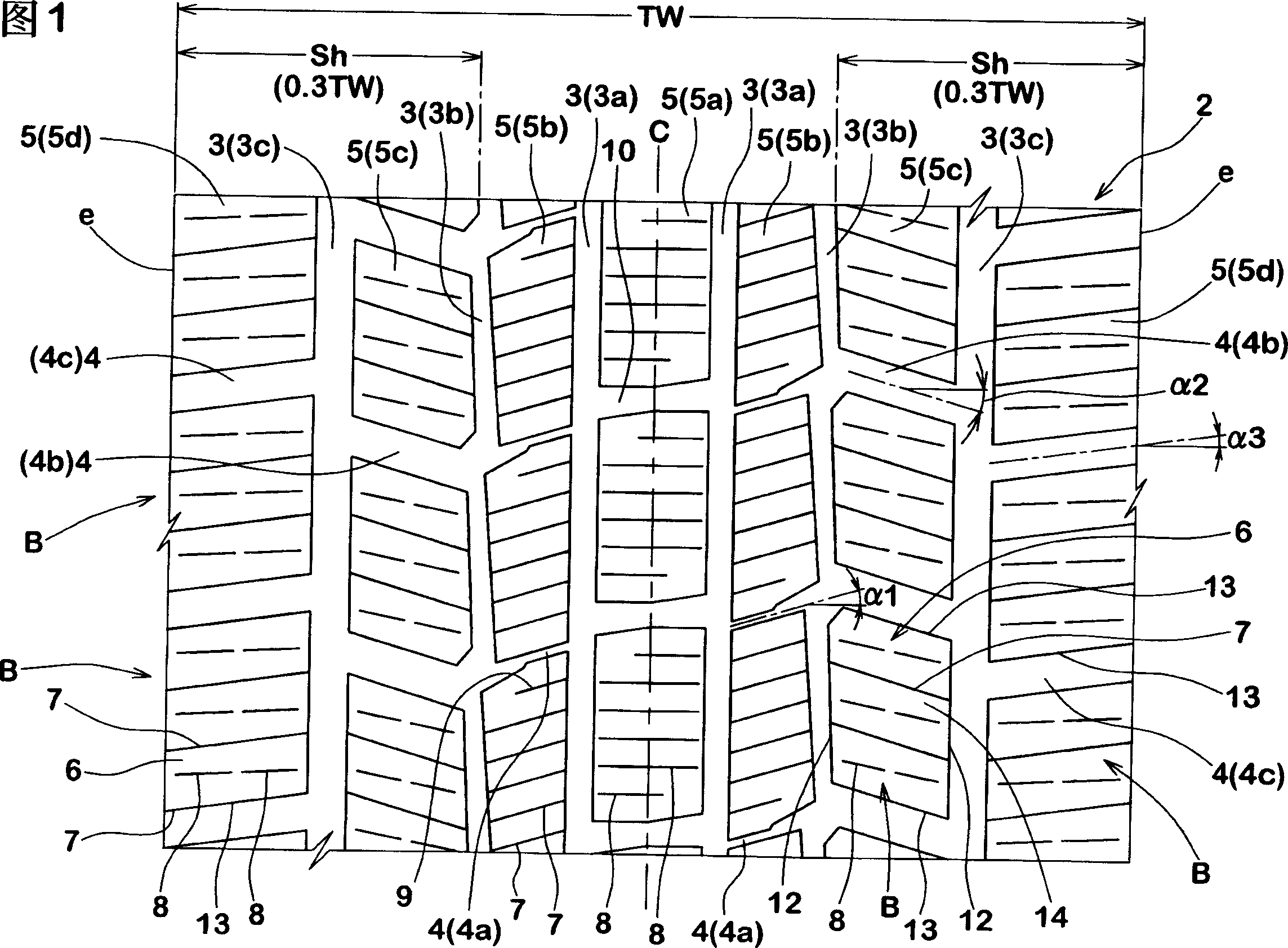

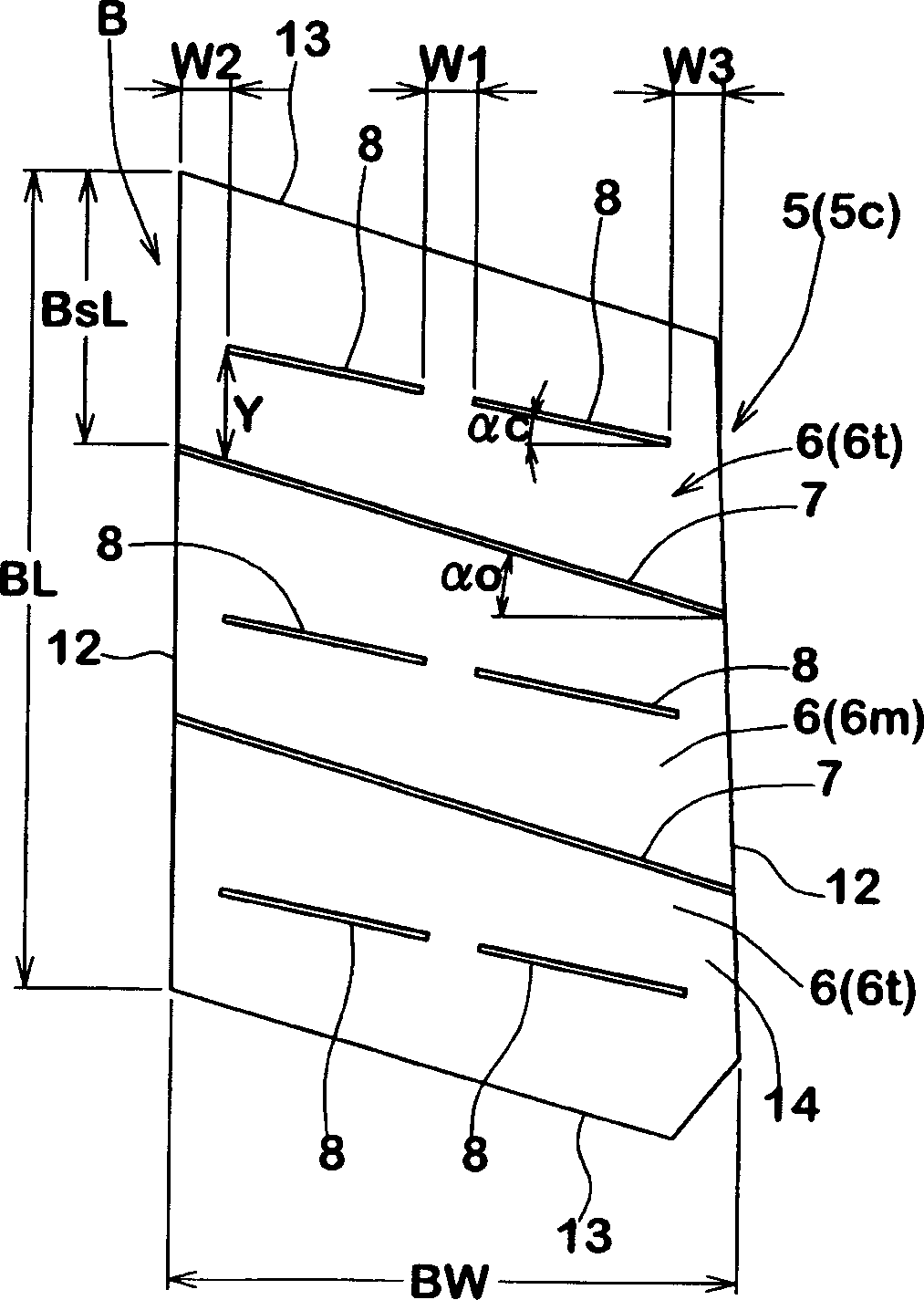

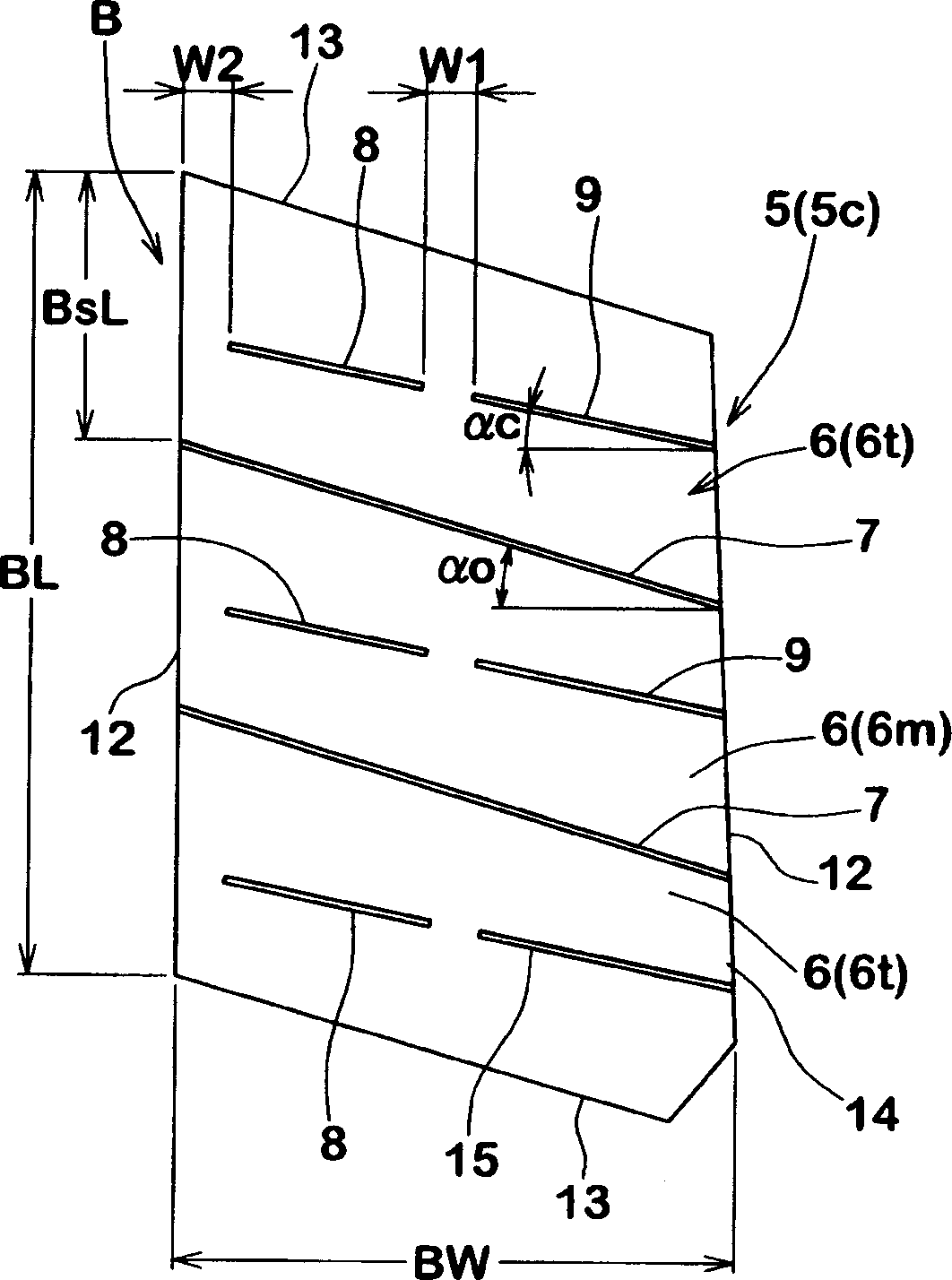

[0010] As is known in the art, a pneumatic tire comprises: a tread portion 2, the outer surface of which defines a ground contacting area; a pair of axially spaced apart bead portions, each with a bead core therein; a pair of sidewall portions extending between the tread edge (e) and the bead portion; a carcass extending between the bead portions through the tread and the sidewall portion; and a tread Part of the tread reinforcement belt is radially arranged on the outside of the carcass.

[0011] Incidentally, the tread edge (e) refers to the axially outermost edge of the ground contact area under a standard load condition in which a tire is mounted on a standard rim and inflated to a standard load and then loaded with a standard load . A standard rim refers to a rim for a tire certified by a standardization organization, ie, JATMA (Japan and Asia), T&RA (North America), ETRTO (Europe), STRO (Scandinavia), and the like. Standard pressure and standard tire load are the maxim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com