Floor accurate pressing technique and dedicated dies thereof

A floor and mold technology, which is applied in the field of technology and its special molds, can solve the problems of production cost reduction, and achieve the effect of production cost reduction and simple processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

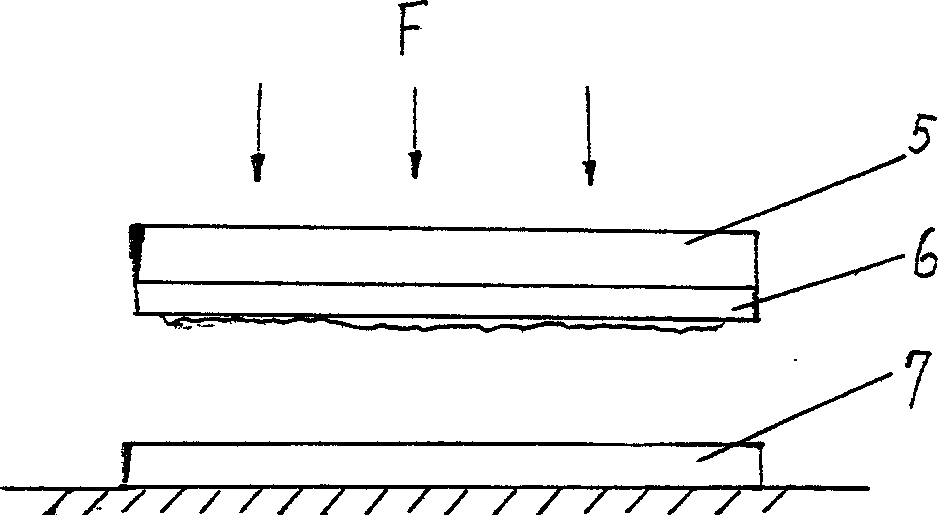

[0031] The specific steps of precise floor pressing are as follows:

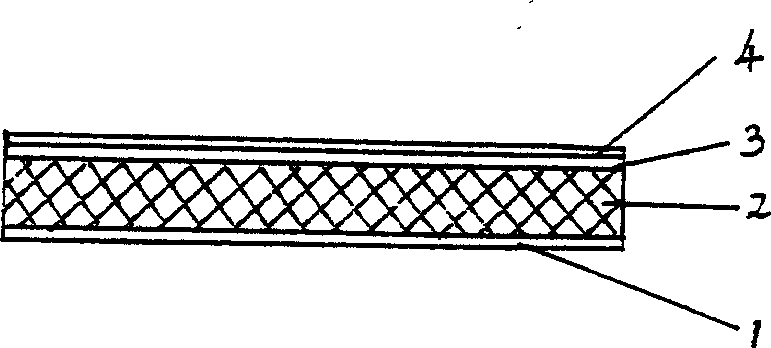

[0032] (1) At a temperature of 190°C and a pressure of 20kg / cm 2 Next, press the impregnated balance paper, decorative paper, wear-resistant layer and density board to get the whole floor;

[0033] (2) Cut the entire floor obtained in step (1) according to specifications (such as 800×125mm);

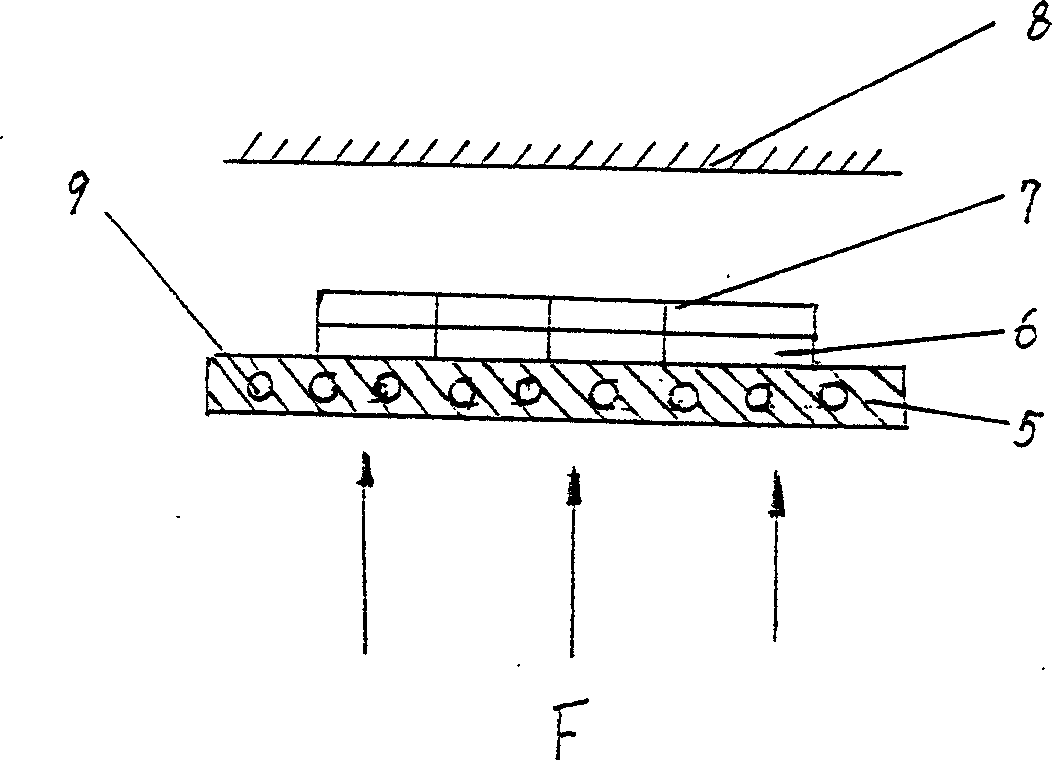

[0034] (3) At a temperature of 160°C and a pressure of 8kg / cm 2 Next, a simulated wood grain structure is formed on the floor surface.

Embodiment 2

[0036] The difference from Example 1 is that the specific steps of precise floor pressing are as follows:

[0037] (1) At a temperature of 200°C and a pressure of 18kg / cm 2 Next, press the impregnated balance paper, decorative paper, wear-resistant layer and density board to get the whole floor;

[0038] (2) Cut the entire floor obtained in step (1) according to specifications (such as 800×125mm);

[0039] (3) At a temperature of 150°C and a pressure of 10kg / cm 2 Next, a simulated wood grain structure is formed on the floor surface.

Embodiment 3

[0041] The difference from Example 1 is that the specific steps of precise floor pressing are as follows:

[0042] (1) At a temperature of 220°C and a pressure of 15kg / cm 2 Next, press the impregnated balance paper, decorative paper, wear-resistant layer and density board to get the whole floor;

[0043] (2) Cut the entire floor obtained in step (1) according to specifications (such as 800×125mm);

[0044] (3) At a temperature of 140°C and a pressure of 12kg / cm 2 Next, a simulated wood grain structure is formed on the floor surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com