Beet root kvass

A red beet and kvass technology, applied in the field of red beet kvass beverages, can solve problems such as incompatibility, complicated process, and difficulty in widely eating red beets, achieve high nutritional and health effects, and simplify the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Raw materials 40kg red beet 20kg white sugar 200kg water

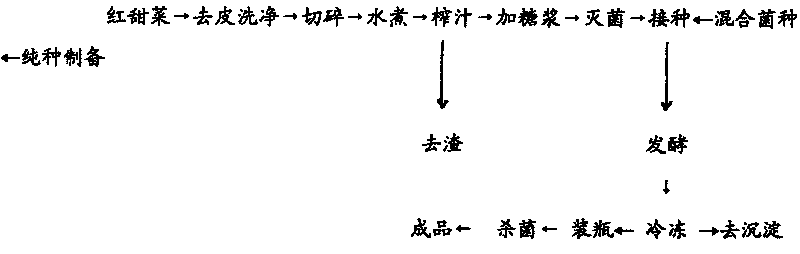

[0021] Production method: combined figure 1 process flow

[0022] 1. Syrup preparation: mix 20 kg of white sugar with water, dissolve for later use.

[0023] 2. Strain preparation: Leuconostoc enterococci and S.C.H.1468 wine yeast were respectively subjected to pure tertiary culture, and then mixed at a ratio of 1:1 or 1.5:1 to cultivate and produce strains at normal temperature. After about 24 hours, the cell count should reach 1.5 x 10 5 -5×10 6 / ml

[0024] 3. Peel off the residual roots and bark of fresh red beets, and wash them well. Cut into fine grains (less than 3 mm) on a vegetable cutter, put them in a pot, add 60 kg of water, and cook at 65°C for 5 minutes. After decanting, add 60kg of water to the original dish and cook again; such three times of vegetable juice are poured into the fermenter in turn. (Vegetable dregs can be used as feed) Then inject syrup into the tank and stir well. Raise th...

Embodiment 2

[0026] Raw materials: 50 kg of red beet, 10 kg of white sugar, 0.2 kg of sweetener, 230 kg of water, 12 liters of mixed strains

[0027] The preparation process is the same as Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com