Arrangement for production of a three dimensional object

A three-dimensional object and three-dimensional technology, applied in the field of devices for manufacturing three-dimensional objects, can solve problems such as shape deviation and crack formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

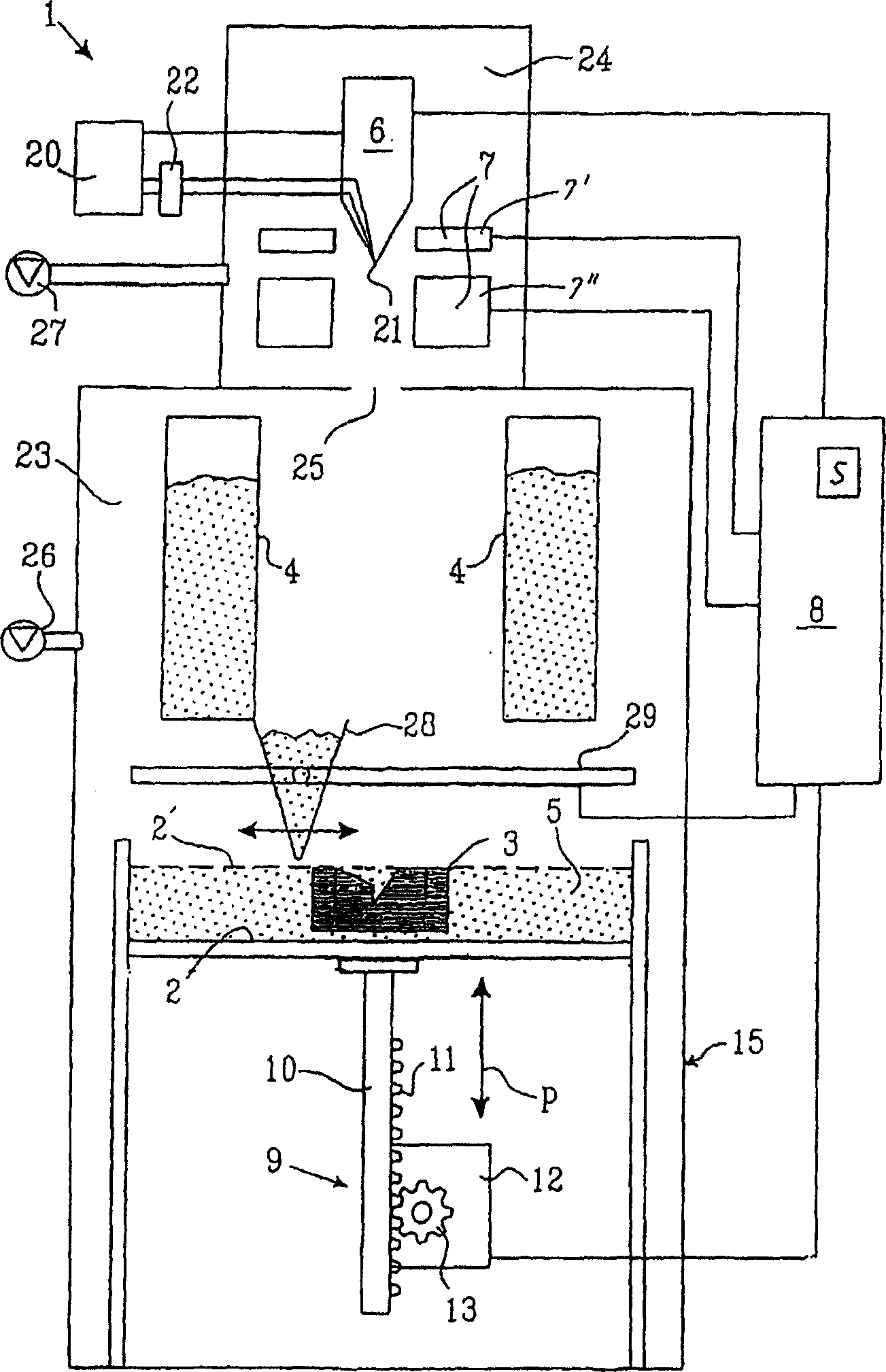

[0033] figure 1 Indicates a device for manufacturing three-dimensional products and is generally identified as 1. The device comprises: a table 2 on which a three-dimensional product 3 is constructed, one or more powder dispensers 4 and means 28 arranged to distribute a thin layer of powder onto the table 2 to form a powder layer 5, a radiation gun 6 for directing the beam of the radiation gun 6 onto the table to fuse together the powder to form the Means 7 of cross-sections of the three-dimensional product, and a control computer 8 in which information relating to successive cross-sections of the three-dimensional product is stored, wherein the cross-sections constitute the three-dimensional product. According to the preferred embodiment shown, the table will be gradually lowered relative to the radiation gun after each powder layer is applied during the working cycle. To make this movement possible, in a preferred embodiment of the invention, the table is arranged to be mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com