Treating fluid for surface treatment of metal and method for surface treatment

A metal surface treatment and surface treatment technology, which is applied in the direction of metal material coating process, electrolytic inorganic material coating, anodic oxidation, etc., can solve the problems of inability to perform surface treatment and difficult coating treatment, etc.

Active Publication Date: 2006-01-25

NIHON PARKERIZING +2

View PDF8 Cites 26 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, similar to the invention disclosed in the above-mentioned Japanese Patent Application Laid-Open No. 2000-204485, since the film is formed by coating and drying, it is difficult to apply a uniform film treatment to complex structures such as automobile bodies.

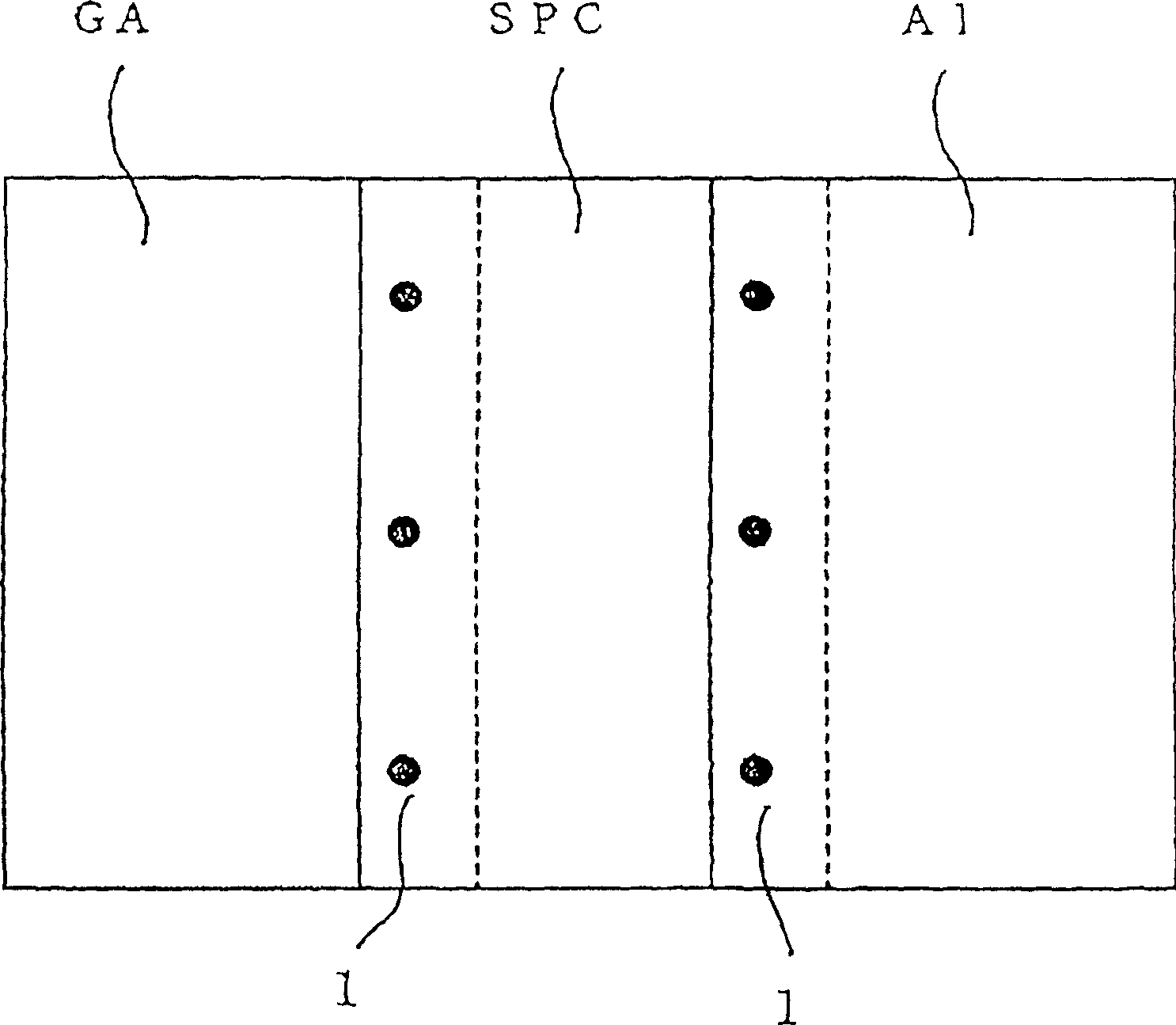

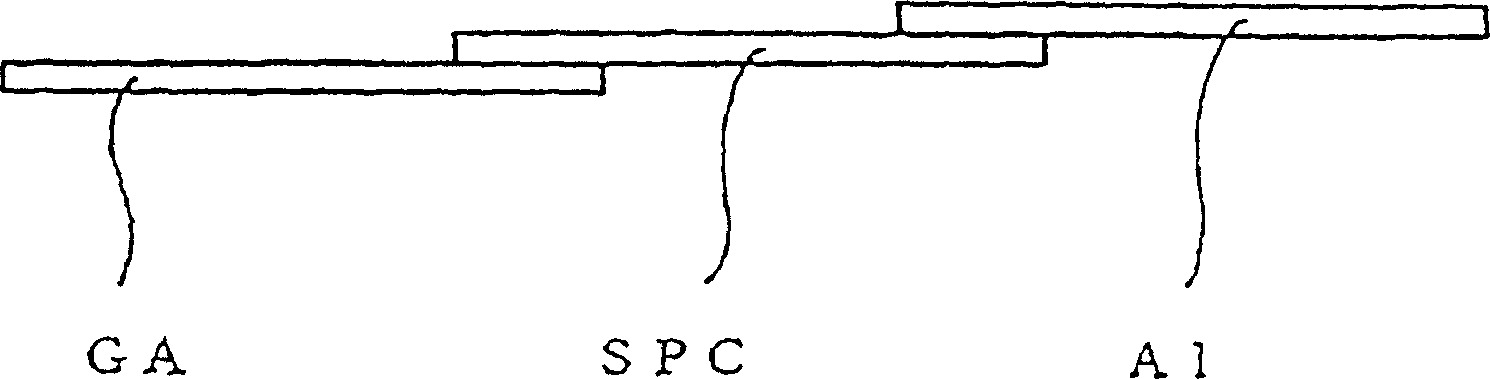

[0007] Therefore, the following surface treatment cannot be performed with the prior art: iron-based materials such as cold-rolled steel sheets such as automobile bodies and galvanized Simultaneous treatment of two to four types of zinc-based materials such as steel sheets, aluminum-based and magnesium-based materials, and surface treatment with excellent corrosion resistance and adhesion

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1-4、 Embodiment 7 and comparative example 1-4

[0054] Examples 1-4, Example 7, and Comparative Examples 1-4: Alkaline degreasing→water washing→film formation treatment→water washing→pure water washing→drying

Embodiment 5

[0055] Example 5: Alkaline degreasing→Washing→Electrolytic film formation treatment→Washing→Pure water washing→Drying

Embodiment 6

[0056] Example 6: Film formation treatment (combined degreasing treatment) → water washing → pure water washing → drying

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Adhesion amount | aaaaa | aaaaa |

Login to View More

Abstract

The present invention provides surface treatment liquid for a surface treatment capsule, which contains no ingredients that are harmful to the environment, produces no waste sludge, is capable of separating coating on a metal surface, and has excellent corrosion resistance; and the present invention provides a surface treatment method. In particular, the present invention provides metal surface treatment liquid and aqueous surface treatment liquid that can be used for the surface treatment of one or more than two metal materials that are chosen from iron materials, zinc materials, aluminum materials and magnesium materials. The liquid contains metal elements that contain 5ppm to 5000ppm of more than one compound that are chosen from zirconium compounds and titanium compounds, and 0.1ppm to 100 ppm of free fluorion; and the pH value is 2 to 6. Thus the treatment liquid can contain calcium compounds, magnesium compounds or strontium compounds, nitrate, oxyacid and / or oxysalt, polymers and surfactants. The capsule can be formed when a metal material contacts the treatment liquid or is electrolyzed in the liquid.

Description

technical field [0001] The present invention relates to a treatment liquid for surface treatment and a surface treatment method, which are applied to structures containing iron-based materials, zinc-based materials, aluminum-based materials, and magnesium-based materials alone or two to four kinds thereof, represented by automobile bodies. On the surface of metal materials, it is possible to separate the surface treatment film with excellent corrosion resistance after painting alone or two to four kinds of it simultaneously. Background technique [0002] As a method of depositing a surface-treated film excellent in corrosion resistance after painting on the metal surface, zinc phosphate treatment or chromate treatment is generally used at present. Zinc phosphate treatment can deposit a film with excellent corrosion resistance on the surface of steel such as cold-rolled steel sheets, galvanized steel sheets, and some aluminum alloys. However, when zinc phosphate treatment is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C23C22/34C25D11/08C23C22/40C23C22/44C23C22/66C23C22/72C23C22/83C25D9/08C25D11/30C25D11/34

CPCC23C22/34C23C22/83C25D9/08C23C22/44C23C22/76

Inventor 中山隆臣佐藤裕之相岛敏行冈田荣作吉田文也盐田克博

Owner NIHON PARKERIZING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com