Dry type lubrican for wheel rail

A lubricant, dry technology, applied in the field of wheel and rail lubrication, can solve the problems of affecting the rail flaw detection operation, speeding up the stripping off of the rail, and the wear reduction effect is not obvious. Good grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

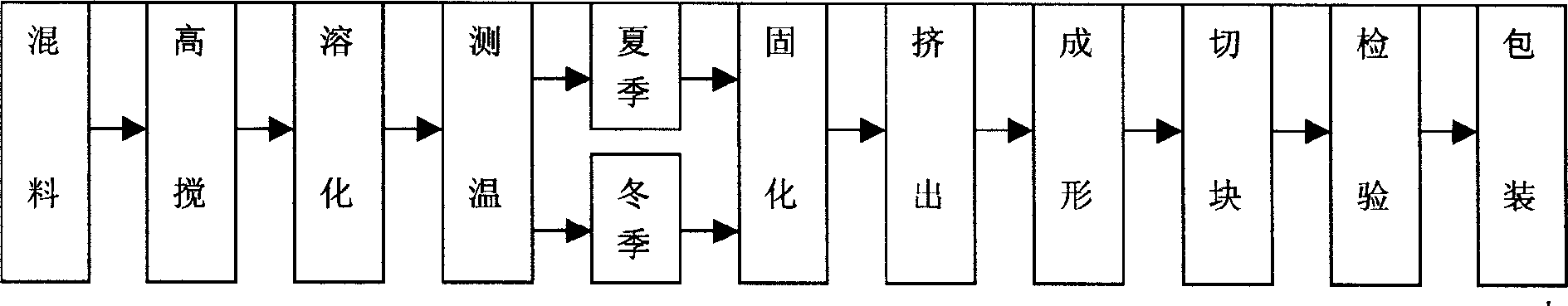

Image

Examples

Embodiment 1

[0036] A kind of dry lubricant for wheel and rail, comprising the raw materials of following composition, by weight percentage,

[0037] Main film-forming substances: synthetic resin and polymeric oil account for 32%, and the ratio between synthetic resin and polymeric oil is 6:4; synthetic resin is synthesized from urea-formaldehyde resin and melamine resin at a ratio of 1:1; polymeric oil is composed of oily agent It is composed of 1:1 with the polymer, the oily agent is vulcanized olefin cottonseed oil, and the polymer is polymethacrylate PMMA;

[0038] Secondary film-forming substances: refers to the composition of soft metals, layered substances and polymers, accounting for 40%, the ratio of soft metals, layered substances and polymers is 3:5:2; soft metals are nickel, zinc, tin Metal oxide; the layered substance is graphite, molybdenum disulfide, mica, MCA, the ratio is 3:6:2:1; the high polymer is PTFE powder;

[0039] Extreme pressure anti-wear additive: 8%; extreme p...

Embodiment 2

[0046] A kind of dry lubricant for wheel and rail, comprising the raw materials of following composition, by weight percentage,

[0047] Main film-forming substances: synthetic resin and polymeric oil account for 32%, and the ratio between synthetic resin and polymeric oil is 6:4; synthetic resin is synthesized from urea-formaldehyde resin and melamine resin at a ratio of 1:1; polymeric oil is composed of oily agent It is composed of 1:1 with the polymer, the oily agent is vulcanized olefin cottonseed oil, and the polymer is polymethacrylate PMMA;

[0048] Secondary film-forming substances: refers to the composition of soft metals, layered substances and polymers, accounting for 40%, the ratio of soft metals, layered substances and polymers is 3:5:2; soft metals are nickel, zinc, tin Metal oxide; the layered substance is graphite, molybdenum disulfide, mica, MCA, the ratio is 3:6:2:1; the high polymer is PTFE powder;

[0049] Extreme pressure anti-wear additive: 7%; extreme p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com