Cleaning production method of raw drug N-trimethyl lysine and application method

A technology of trimethyl lysine and a production method is applied in the field of clean production and application of raw material drug-N-trimethyl lysine, and can solve the problems of difficulty in guaranteeing the quality of laminine, pollution of factory areas and environment, etc. , to eliminate the danger of polluting the production workshop and the environment, achieve good quality, and achieve the effect of cleaner production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

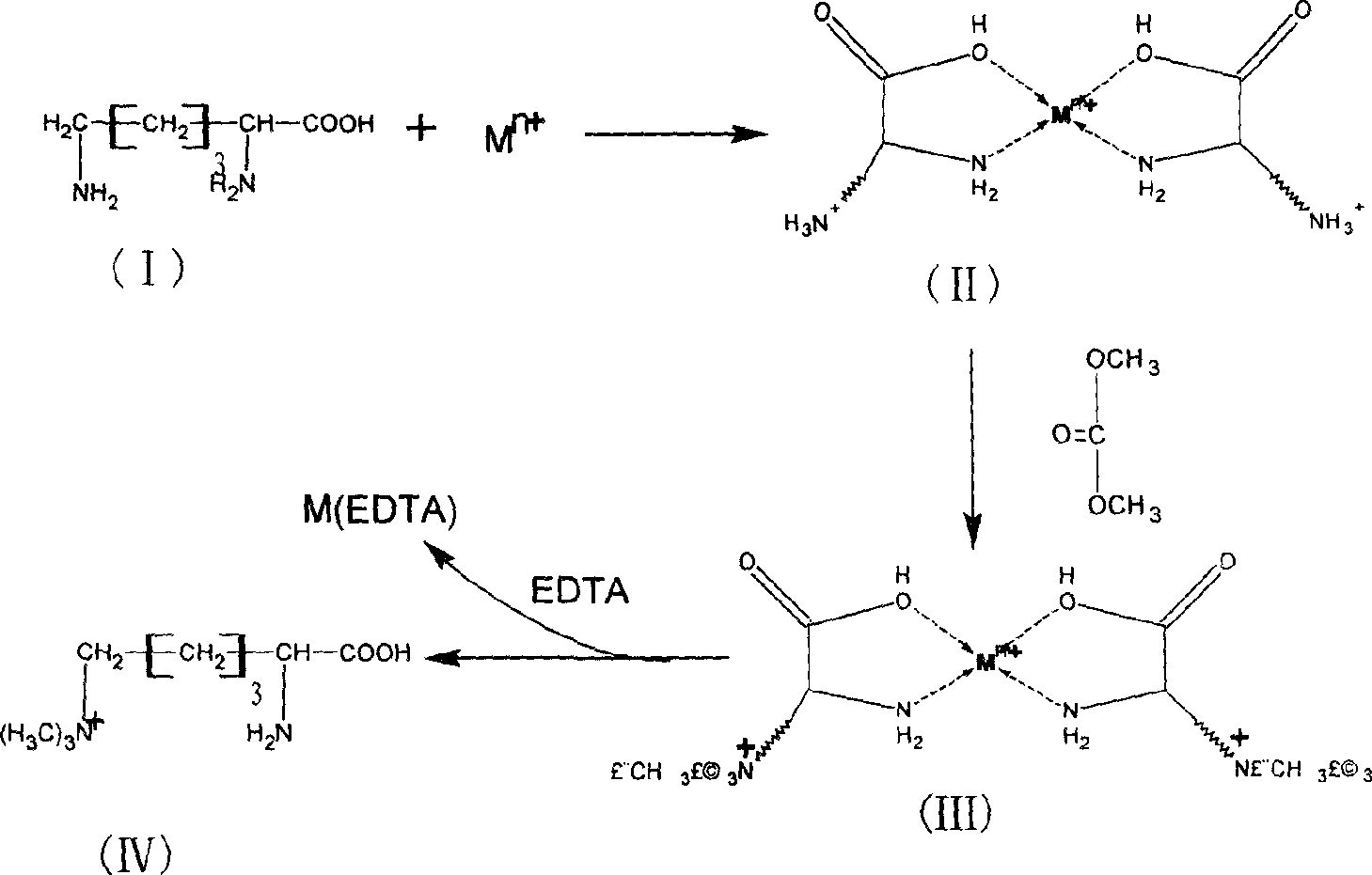

Embodiment 1

[0029] In the 500L reaction kettle, first add 300 kg of distilled water, weigh 75 kg of food grade (feed grade) zinc sulfate and stir for 20 minutes to dissolve, and then slowly add 91 kg of L-lysine hydrochloride to the reaction kettle under stirring , 60 ℃ constant temperature reaction for 1 hour, let lysine and Zn 2+ The reaction is complete; then react with 135 kilograms of dimethyl carbonate to generate the complex of quaternized lysine derivative, then with 79 kilograms of ethylenediaminetetraacetic acid disodium salt, metal ion unmasking reaction occurs to obtain N-trimethyl The crude lysine product was finally adsorbed N-trimethyl lysine using a strong acid cation resin exchange column, washed with deionized water or ethanol, concentrated under negative pressure, and crystallized to obtain 110 kilograms of raw material N-trimethyl lysine. .

Embodiment 2

[0031] In a 100L reaction kettle, first add 55 kg of distilled water, weigh 13 kg of drinking-grade ferrous sulfate and stir for 20 minutes to dissolve, and then slowly add 19 kg of L-lysine hydrochloride to the reaction kettle under stirring, at 60° C. Constant temperature reaction for 1 hour, let lysine and Fe 2+ The reaction is complete; Then react with 27 kilograms of dimethyl carbonate to generate the complex of quaternized lysine derivative, then with 16 kilograms of ethylenediaminetetraacetic acid disodium salts, the metal ion unmasking reaction occurs to obtain the laminarin crude product, Finally, a strong acid cation resin exchange column was used to adsorb N-trimethyllysine, and 21 kg of raw material N-trimethyllysine was obtained by washing and purifying with deionized water, desorption with dilute ammonia water, vacuum concentration and crystallization.

Embodiment 3

[0033] In a 200L reaction kettle, first add 100 kg of distilled water, weigh 27 kg of feed-grade copper sulfate and stir for 20 minutes to dissolve, then slowly add 37 kg of L-lysine hydrochloride to the reaction kettle under stirring, and keep it at a constant temperature of 60°C. React for 1 hour to allow lysine to react with Cu 2+ The reaction is complete; Then react with 54 kilograms of dimethyl carbonate to generate the complex of quaternized lysine derivative, then with 31 kilograms of ethylenediaminetetraacetic acid disodium salts, the metal ion unmasking reaction takes place to obtain the laminarin crude product, Finally, a strong acid cation resin exchange column is used to adsorb N-trimethyllysine, and 40 kg of raw material N-trimethyllysine is obtained through deionized water washing and purification, dilute ammonia desorption, vacuum concentration and crystallization.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com