Cutting method of hole

A technology for machining and machining platforms, applied in the field of hole machining, can solve the problems of difficulty in achieving machining accuracy, increasing size and shape, and small hole deformation, achieving high machining accuracy and reducing size and shape errors. , the effect of preventing deformation and offset

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

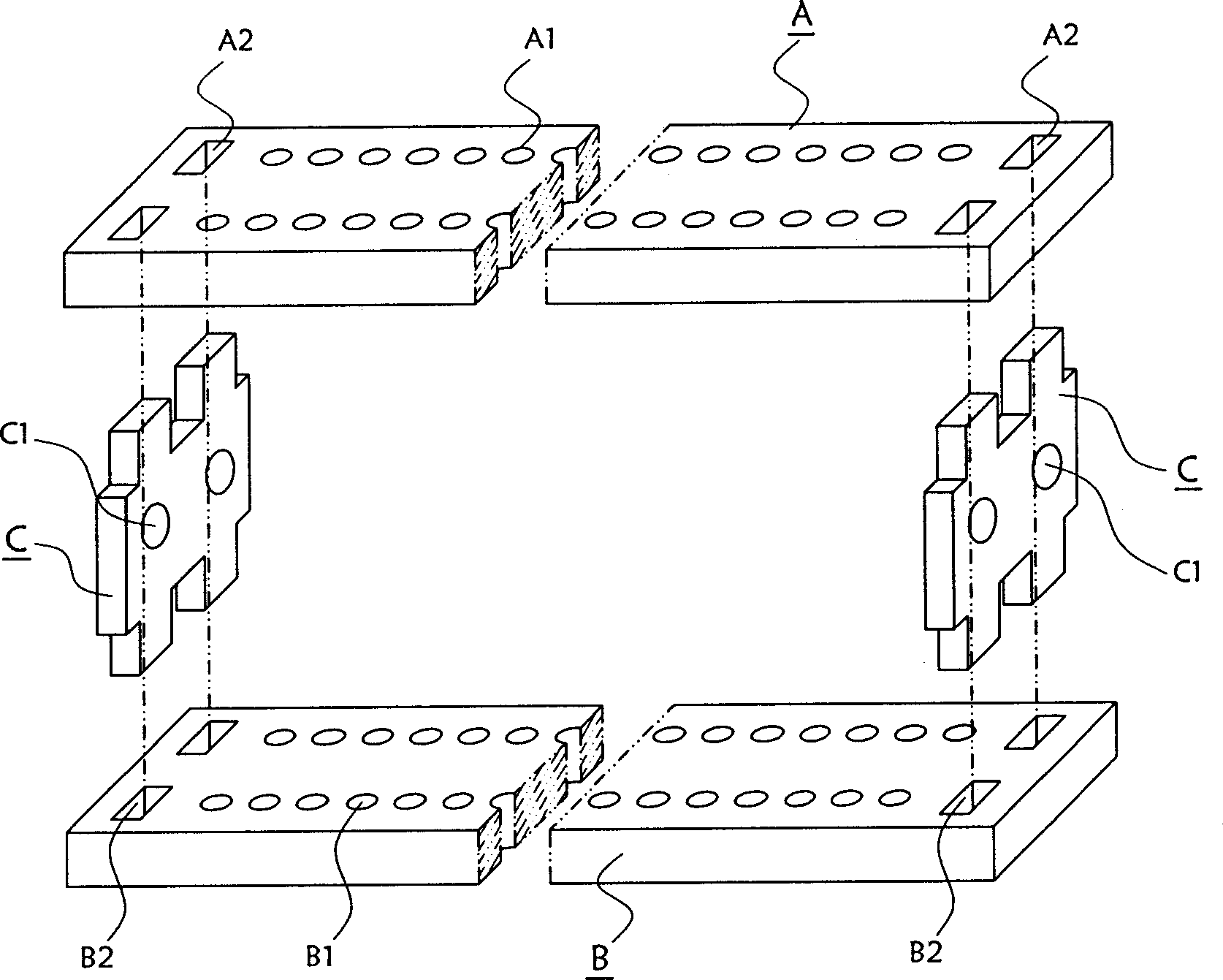

[0012] figure 1 The mold shown includes A template, B template and two supporting positioning splints C, wherein two rows of parallel small orthopedic positioning holes A1 are provided on the A template, and two rows of large orthopedic positioning holes corresponding to the small orthopedic positioning holes are provided on the B template. The orthopedic positioning hole B1, the two ends of the A template and the B template are also provided with supporting holes A2 and B2; two corresponding workpiece positioning parts C1 are respectively provided on the two supporting positioning splints, and the two supporting positioning splints are plugged into the supporting holes In order to ensure the corresponding relationship between the positions of the two templates A and B, make the large and small orthopedic positioning holes on them correspond to each other, and realize the disassembly and connection of the two templates A and B.

[0013] Such as figure 2 As shown, first insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com