Breathing protective mask from secondary injecting formation and production thereof

A respiratory protector and secondary injection molding technology, which is applied in the direction of respiratory protective containers, respiratory masks, life-saving equipment, etc., can solve the problem of uneven welding state between hard bracket and soft cover, large welding energy time pressure limit, and difficult for workers to master and other issues to achieve the effect of improving product quality, reducing uncertain factors, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically described below in conjunction with specific embodiments.

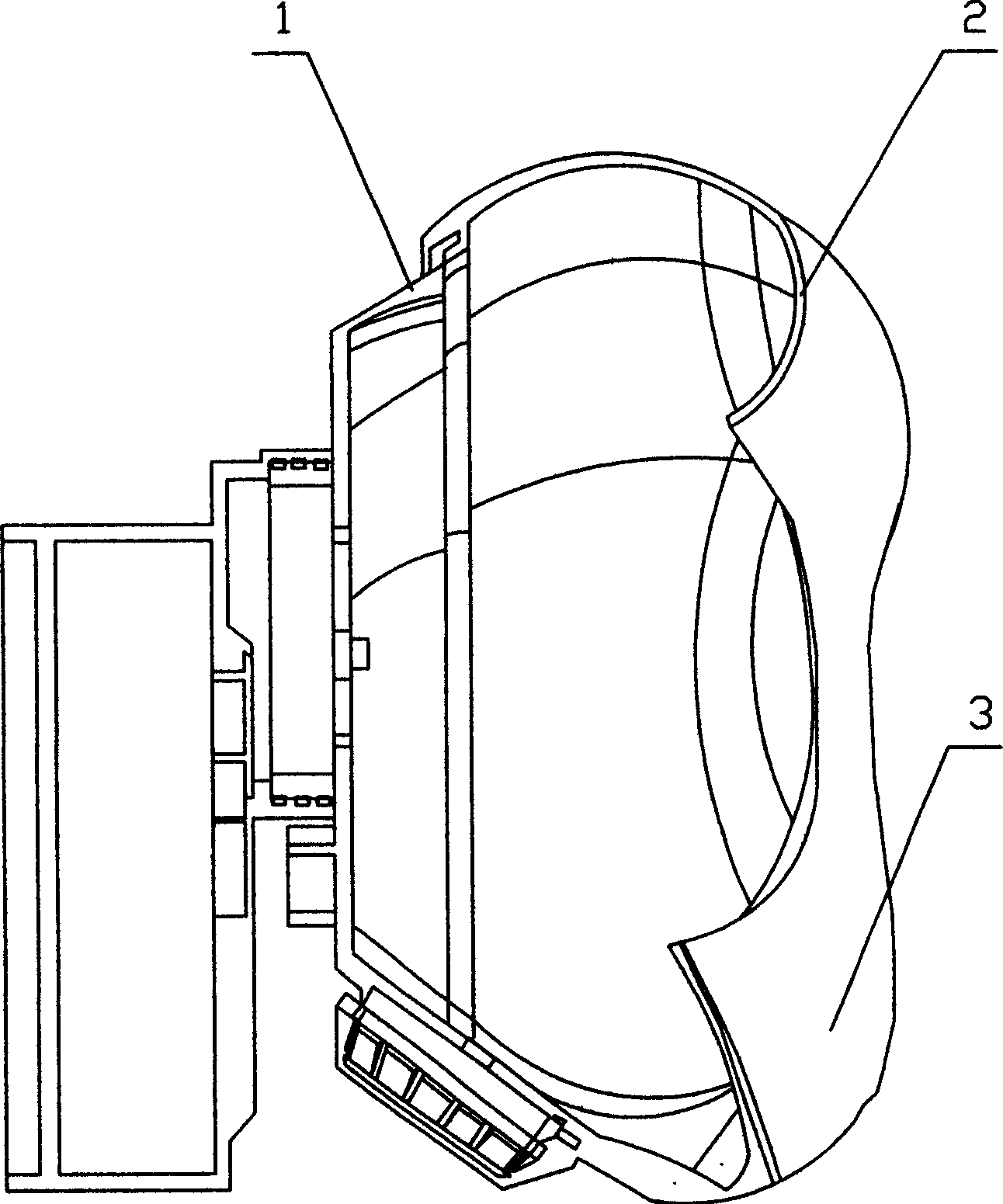

[0021] Such as figure 1 As shown, the present embodiment is composed of a hard bracket 1 and a soft cover 2. The front part of the hard bracket 1 is connected with the soft cover 2, and the rear part is connected with the container structure of the respiratory protector. The size and shape of the soft cover 2 It matches the nose and mouth of a person, and can tightly cover the nose and mouth of the user; the connection between the soft cover 2 and the hard bracket 1 is secondary injection molding.

[0022] The manufacturing steps of this embodiment are as follows:

[0023] 1) One-time injection molding, injecting molten polypropylene (PE) into the mold, and injection molding the hard support 1;

[0024] 2) Secondary injection molding, after cooling and opening the mold, put the formed hard bracket 1 into the soft cover mold, and inject thermoplastic elastomer (TPE) i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com