Single-acid micro adding device and method

A technology of adding devices and single acid, which is applied in the field of wet etching equipment, can solve the problems of unstable etching rate of the process, large fluctuations in the concentration of single acid A, and short acid change cycle, so as to maintain the metal etch rate, prolong the acid change cycle, The effect of monoacid concentration stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

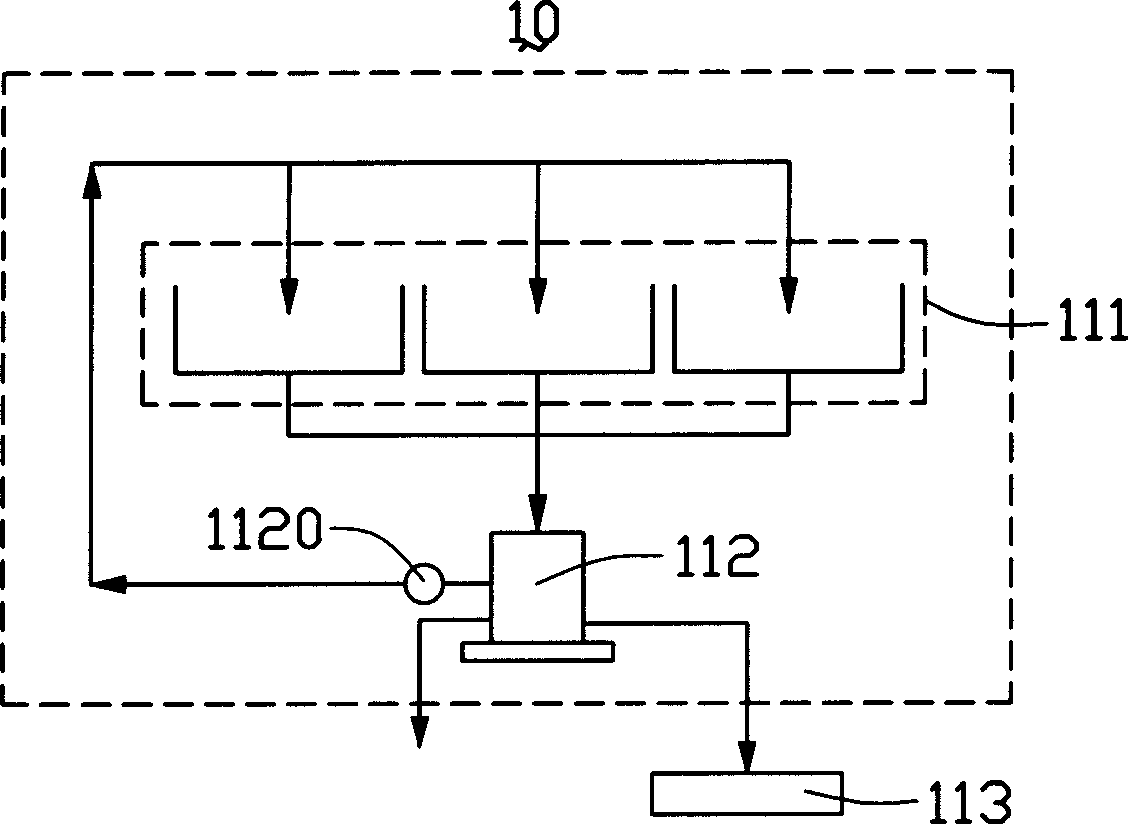

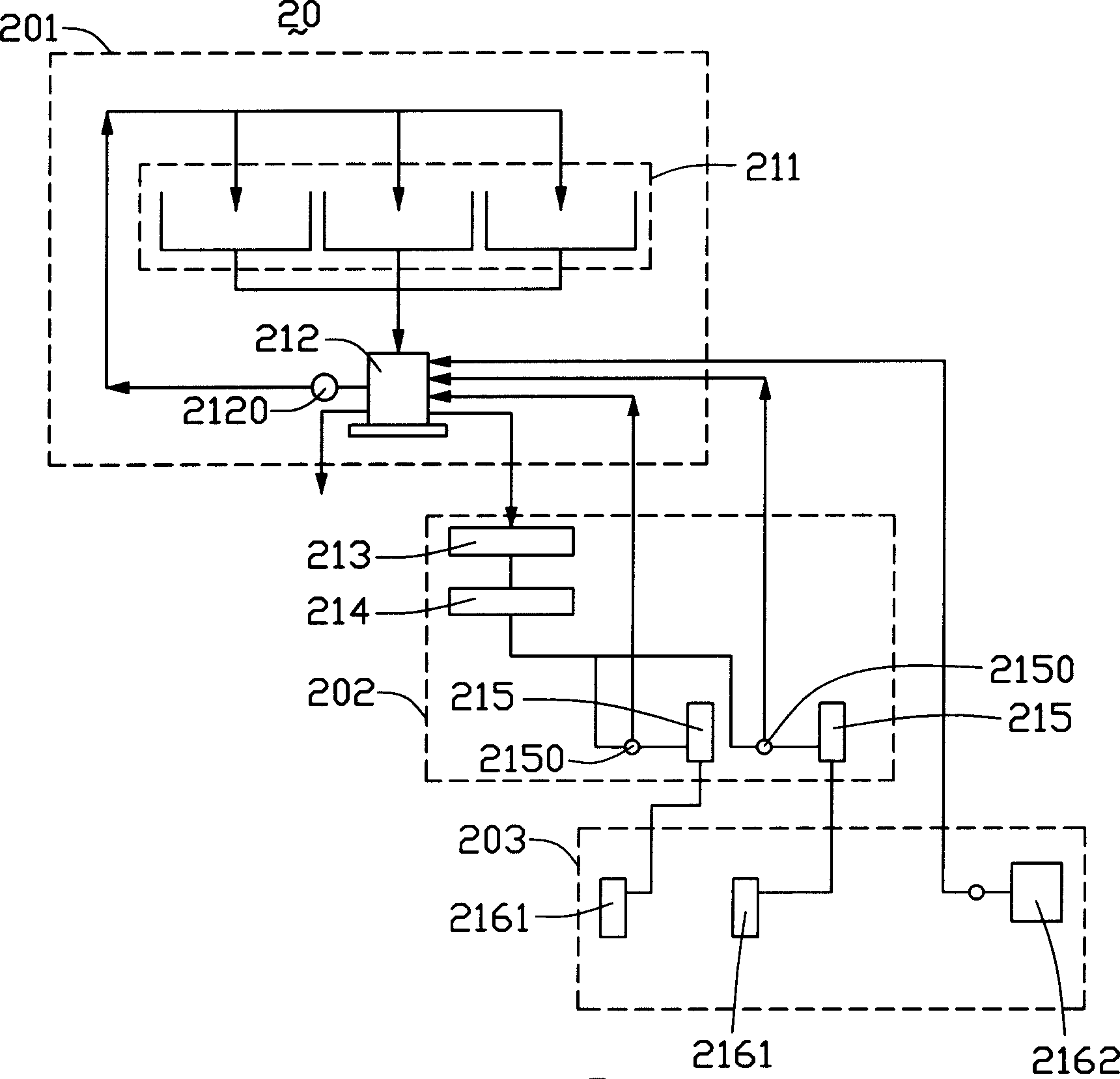

[0016] see figure 2 , is a structural schematic diagram of an embodiment of the monoacid micro-addition device of the present invention. This single acid trace addition device 20 comprises an etching unit 201, a monitoring adding unit 202 and a central chemical supply unit 203, and the etching unit 201 comprises an etching chamber 211, a mixed acid tank 212 and a pump 2120; the monitoring adding unit 202 It includes a single-acid acid measuring instrument 213 , a single-acid replenishment calculator 214 , two single-acid addition tanks 215 and two metering pumps 2150 ; the central chemical supply unit 203 includes two single-acid storage tanks 2161 and a mixed-acid storage tank 2162 .

[0017] The mixed acid liquid of this mixed acid tank 212 is injected in this etching chamber 211 from the top by the pump 2120 that is connected with it; Mixed acid finishes the etching step to metal in etching chamber 211; The waste liquid after etching is discharged back to the mixed acid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com