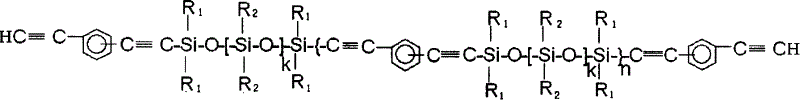

Aryne resin containing silicone

An arylalkyne resin and siloxane technology, applied in the field of siloxane-containing arylalkyne resins, can solve the problems of poor material performance, difficult processing and molding, and high reaction temperature, and achieves convenient application, easy curing, and low curing temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030]

[0031]Soak the magnesium powder with 5% dilute hydrochloric acid for 2-3 minutes, and then filter with suction; then wash with deionized water three times, and filter with suction; wash with absolute ethanol for three times, and filter with suction; finally wash with petroleum ether for three times, and filter with suction After drying, the magnesium powder that can be used can be obtained. The 500ml four-necked round-bottomed flask equipped with constant pressure funnel, spherical condenser, ventilation tube / thermometer and stirrer was evacuated and filled with nitrogen, and replaced like this three times; under nitrogen protection, 3.0g (0.12 mol) magnesium powder and a small amount of iodine crystals, and then add 30ml of tetrahydrofuran (treated with sodium metal to remove water and oxygen), and stir evenly. Add 10.9g (0.10mol) bromoethane and 30ml tetrahydrofuran (THF, dried over sodium metal) mixed solution into the constant pressure funnel, start to drop bro...

Embodiment 2

[0036]

[0037] The 500ml four-neck round-bottomed flask equipped with a 100ml constant pressure funnel, spherical condenser, vent tube / thermometer and stirrer was vacuumized and filled with nitrogen, and replaced like this three times; under nitrogen protection, 3.0g ( 0.12mol) of magnesium powder and a small amount of iodine crystals treated (same as in Example 1), and then 30ml of tetrahydrofuran (dried over sodium metal) was added, and stirred evenly. Add 0.10 mol ethyl bromide and 30 ml tetrahydrofuran (THF, treated with sodium metal to remove water and oxygen) mixture into the constant pressure funnel, start adding bromide / THF mixture dropwise to the flask, and stir rapidly, during which you can see The reaction system changed from light brownish yellow to iron gray, and gradually became turbid. After the dropwise addition, react under heating in an oil bath at 60-66°C for 2 hours to obtain the Grignard reagent of ethyl bromide.

[0038] Add 30ml tetrahydrofuran and ...

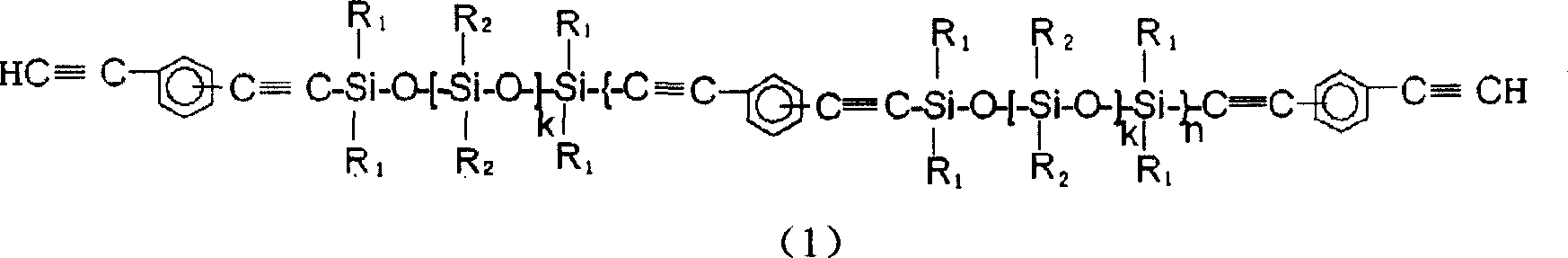

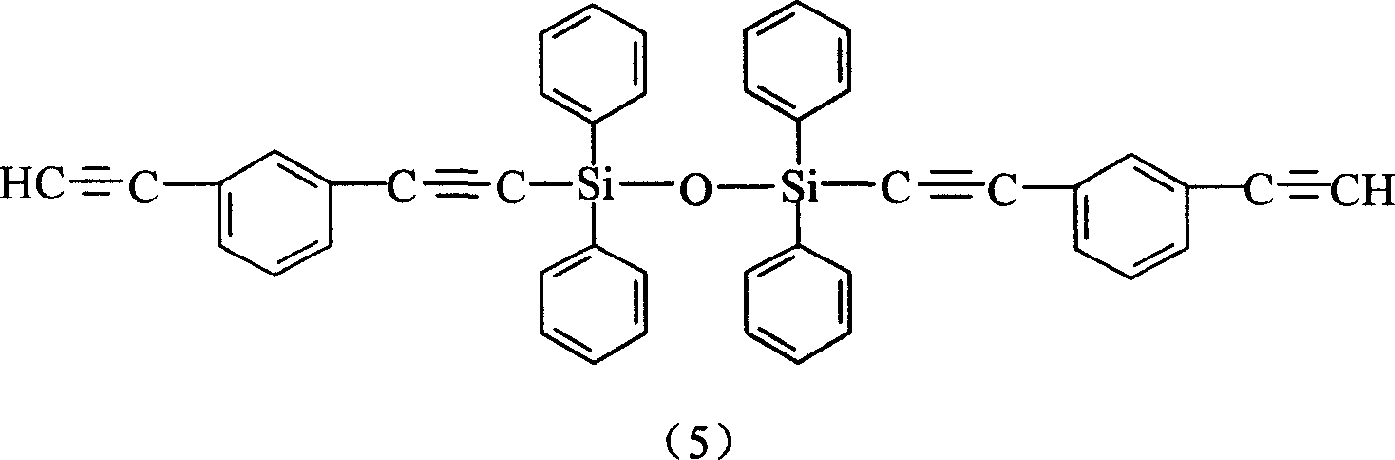

Embodiment 3

[0042]

[0043] Vacuumize a 500ml four-necked round-bottomed flask equipped with a 100ml constant pressure funnel, spherical condenser, vent tube / thermometer and stirrer, then fill it with nitrogen to dehumidify and deoxygenate, and add 0.12mol of magnesium powder to the four-necked flask under nitrogen protection and a small amount of iodine crystals, and then add 30ml of tetrahydrofuran (dried over sodium metal), and stir evenly. Add 0.10 mol of bromoethane and 30 ml of tetrahydrofuran mixture dropwise through a constant pressure funnel, and cool with an ice-water bath while dropping. During the period, it can be seen that the reaction system changes from the original light brown yellow to iron gray, and gradually becomes turbid. After the dropwise addition, react under heating in an oil bath at 60-66°C for 2 hours to obtain the Grignard reagent of ethyl bromide.

[0044] Add 30ml of tetrahydrofuran and 0.0633mol of 1,3-diethynylbenzene into a four-neck round-bottomed fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com