Biomass drying method and plate type biomass dryer

A drying method and biomass technology, which is applied in the field of biomass drying and plate biomass dryer, can solve the problems of land occupation, time-consuming, and affecting crop planting, and achieve extensive heat sources, small water content unevenness, and material layer thickness. adjustable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

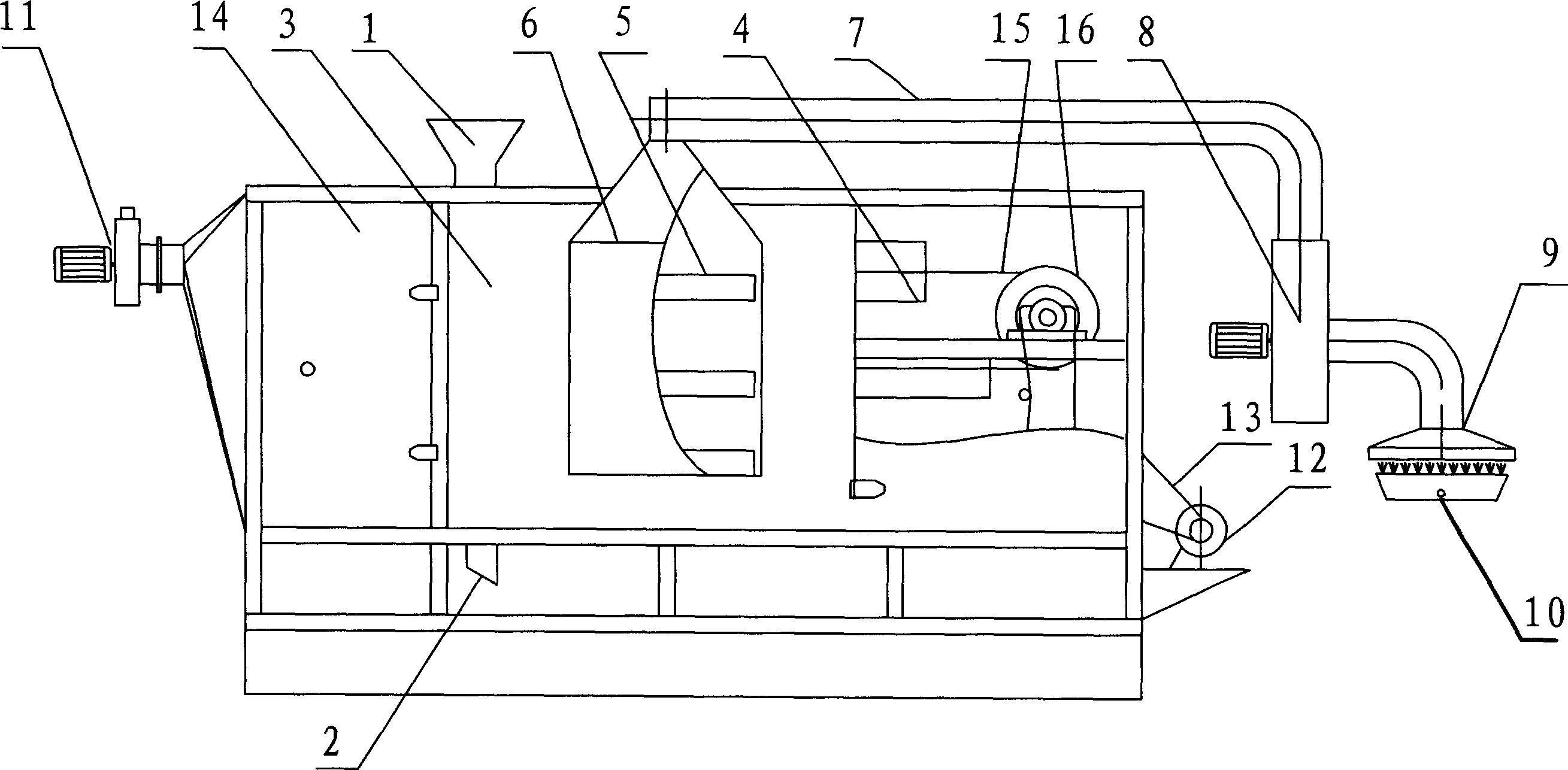

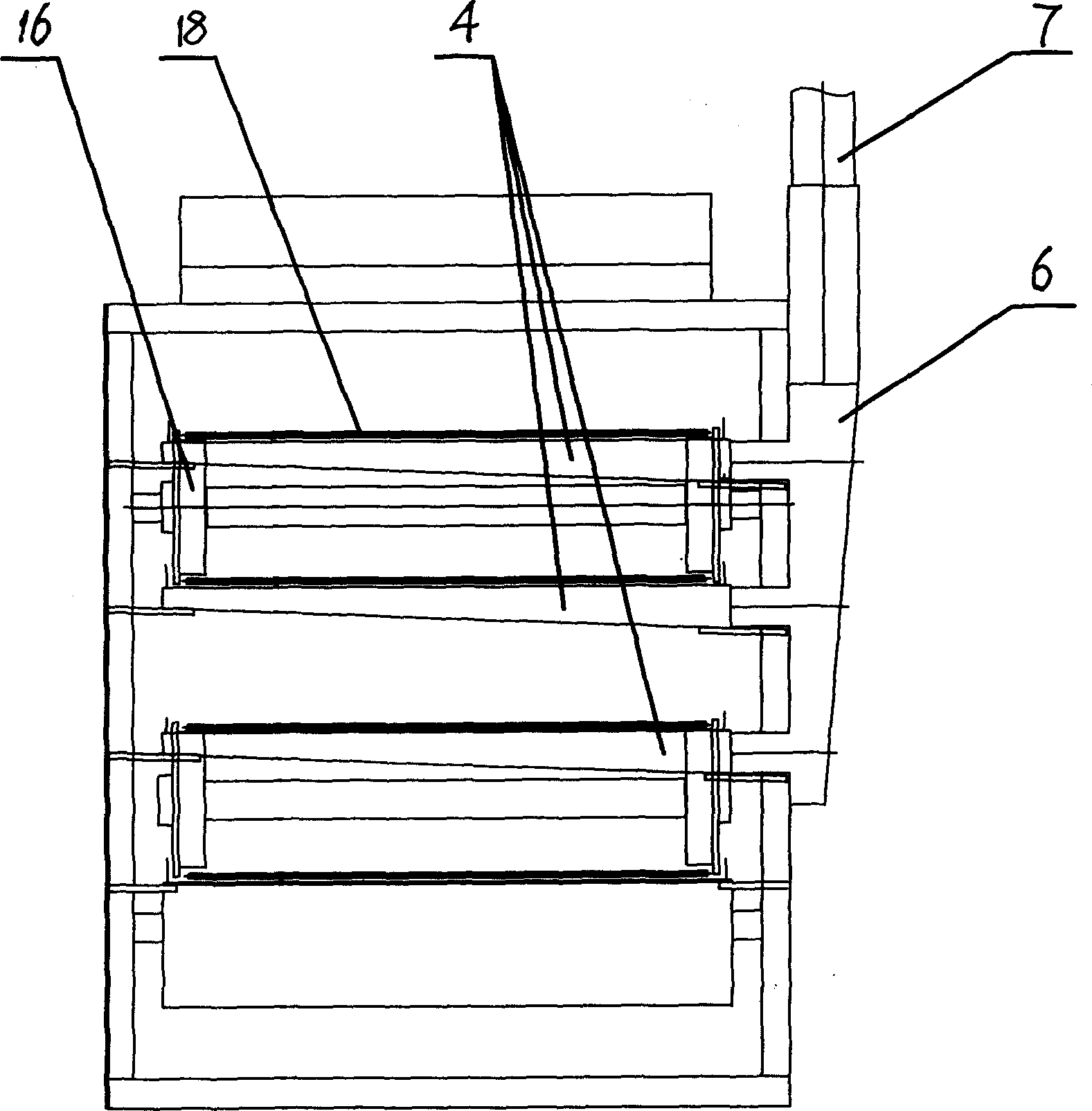

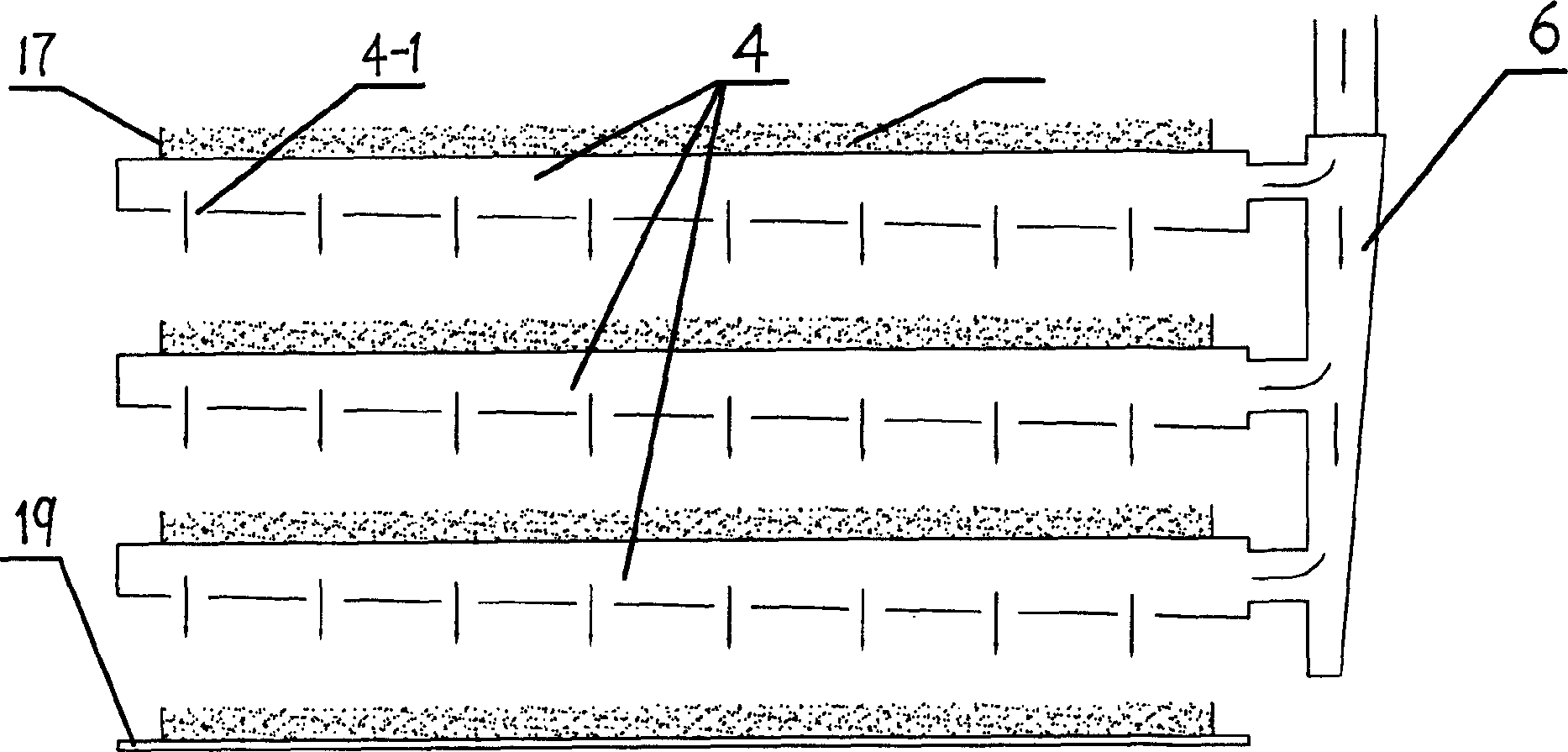

[0017] Embodiment, the plate type biomass dryer, including the insulation box body 3 that is provided with feed inlet 1, discharge outlet 2, inside the box body 3, there are 3 upper surfaces corresponding to the plane, and through holes 4 evenly distributed on the lower surface. 1. A jet plate 4 with a high-temperature gas inlet is provided on the side, and the ends of two adjacent jet plates 4 are staggered left and right. Material baffles 17 are arranged on both sides of the upper surface of the jet plate 4 , the high-temperature gas inlets on the sides of the jet plate 4 communicate with the pressure-stabilizing box 6 respectively, and a dehumidification blower 11 is provided at one end of the box body 3 . The air inlet of the surge box 6 is connected with the air-introduction hood 9 through the air-intake pipe 7, and a high-temperature blower 8 is installed on the air-intake pipe 7, and the air-induction hood 9 covers the burner 10 top. The drive wheel 16 that is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com