Hydrophobic composite polymer film in micron and nanometer structure and its prepn

A hydrophobic polymer and composite film technology, which is applied in the field of hydrophobic polymer composite film and its preparation, can solve problems such as complex methods, and achieve the effects of simple preparation methods, avoiding damage, and broadening the application range and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Prepare potassium hydroxide solution with a concentration of 3mol / L.

[0027] (2) An anodic porous aluminum oxide film with a pore diameter of 200 nm (produced by Whatman Company, UK, trade name Anapore) was used as a material, and chemically etched with an alkaline solution for 5 minutes at a temperature of 23°C.

[0028] (3) Drying: Dry under an infrared lamp for 3 hours at a temperature of 40°C.

[0029] (4) Utilize the solution coating method of dripping, the saturated NMP (N-methylpyrrolidone) of one deck intrinsic state polyaniline is coated on the anodic porous aluminum oxide film substrate with micron and nanostructure of step (3) gained The solution was then dried in an oven at 60 °C for 3 h.

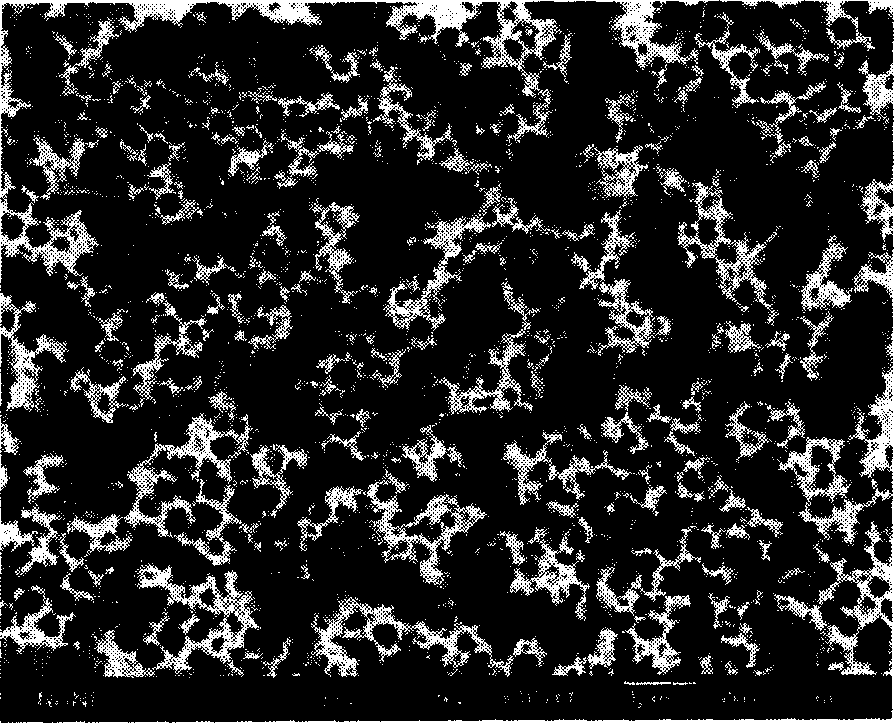

[0030] The wall thickness of the micron-scale pores in the sample is determined by SEM to be 1.5-2.5 μm, and the pore diameter of the micron-scale pores is 0.5-1.0 μm. The average static contact angle of the composite film to water is 144.1°. SEM photos of the sol...

Embodiment 2

[0032] (1) Prepare potassium hydroxide solution with a concentration of 3mol / L.

[0033] (2) An anodic porous aluminum oxide film with a pore diameter of 200 nm (produced by Whatman Company, UK, trade name Anapore) was used as a material, and chemically etched with an alkaline solution for 6 minutes at a temperature of 23°C.

[0034] (3) Drying: Dry in an oven for 3 hours at a temperature of 60°C.

[0035] (4) Utilize the solution coating method of dropping, on the anodic porous aluminum oxide film substrate with micron and nanostructure of step (3) gained, coat the saturated NMP solution of one deck intrinsic state polyaniline, dry in oven then 3 hours at a temperature of 60°C.

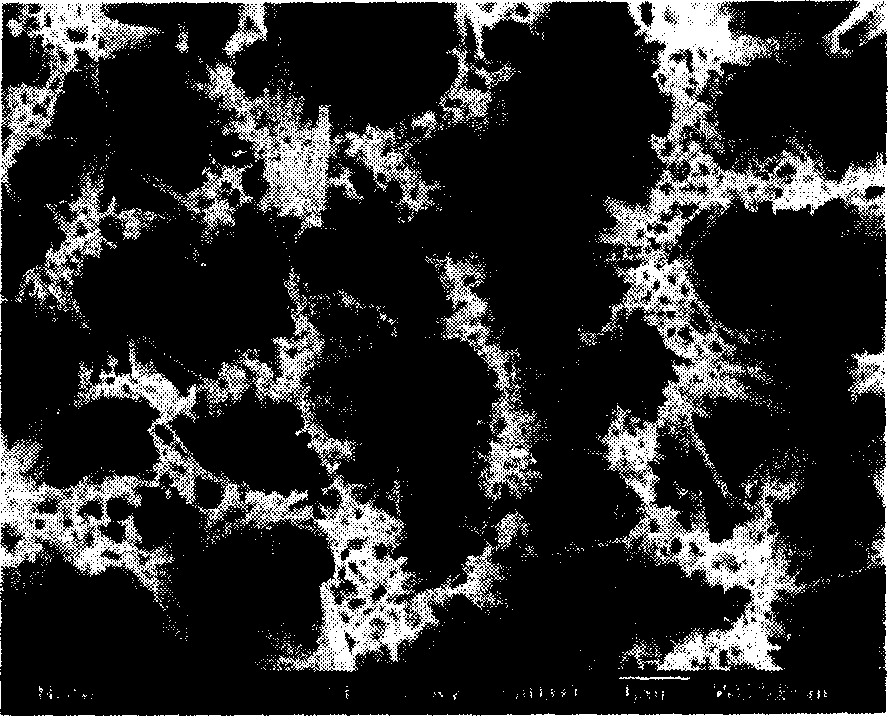

[0036] The wall thickness of the micron-scale pores of the sample is determined by SEM to be 0.5-1.0 μm, and the pore diameter of the micron-scale pores is 2.0-3.0 μm. The average static contact angle of the composite film to water is 148.4°. SEM photos of the solid surface are attached figure 2 ....

Embodiment 3

[0038] (1) Prepare potassium hydroxide solution with a concentration of 3mol / L.

[0039] (2) An anodic porous aluminum oxide film with a pore diameter of 200 nm (produced by Whatman Company of the United Kingdom, trade name Anapore) was used as a material, and chemically etched with an alkaline solution for 3 minutes at a temperature of 24°C.

[0040] (3) Drying: Dry under an infrared lamp for 3 hours at a temperature of 40°C.

[0041] (4) Utilize the solution coating method of dropping, on the anodic porous aluminum oxide film substrate with micron and nanostructure of step (3) gained, coat the saturated NMP solution of one deck intrinsic state polyaniline, dry in oven then 3 hours at a temperature of 60°C.

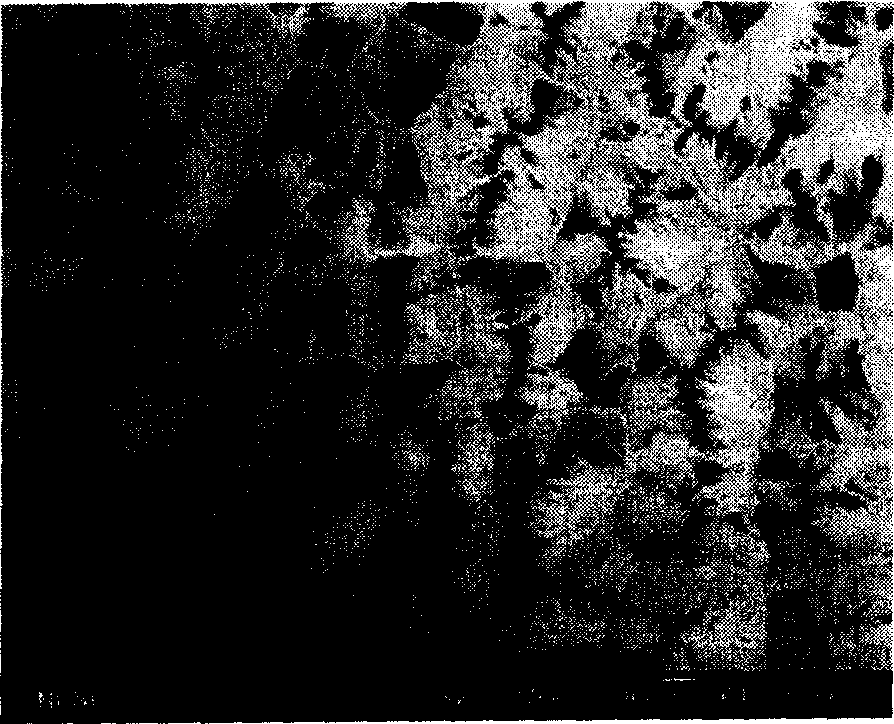

[0042] The wall thickness of the micron-scale pores in the sample is determined by SEM to be about 1.0 μm, and the pore diameter of the micron-scale pores is 5-10 μm. The average static contact angle to water is 147.18°. Scanning electron microscope photographs of sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com