Substrate inspection apparatus

A technology for inspection of substrates and substrates, which is applied to printing devices, measuring devices, components of pumping devices for elastic fluids, etc., can solve the problem of not being able to take pictures of graphics, not being able to clearly distinguish the shade of thin-line graphic grooves, and difficult to obtain Concentration information etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Next, embodiments of the present invention will be described with reference to the drawings.

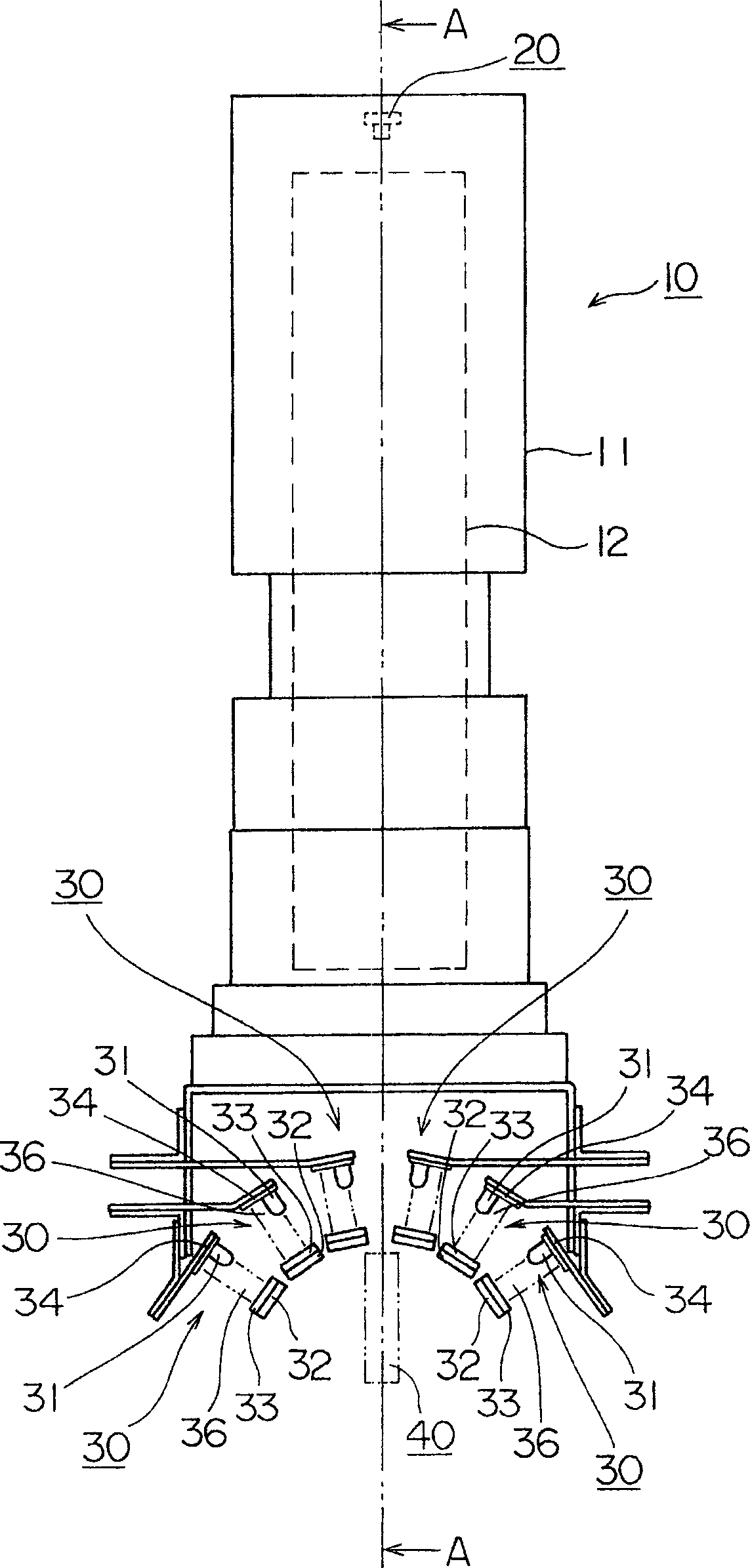

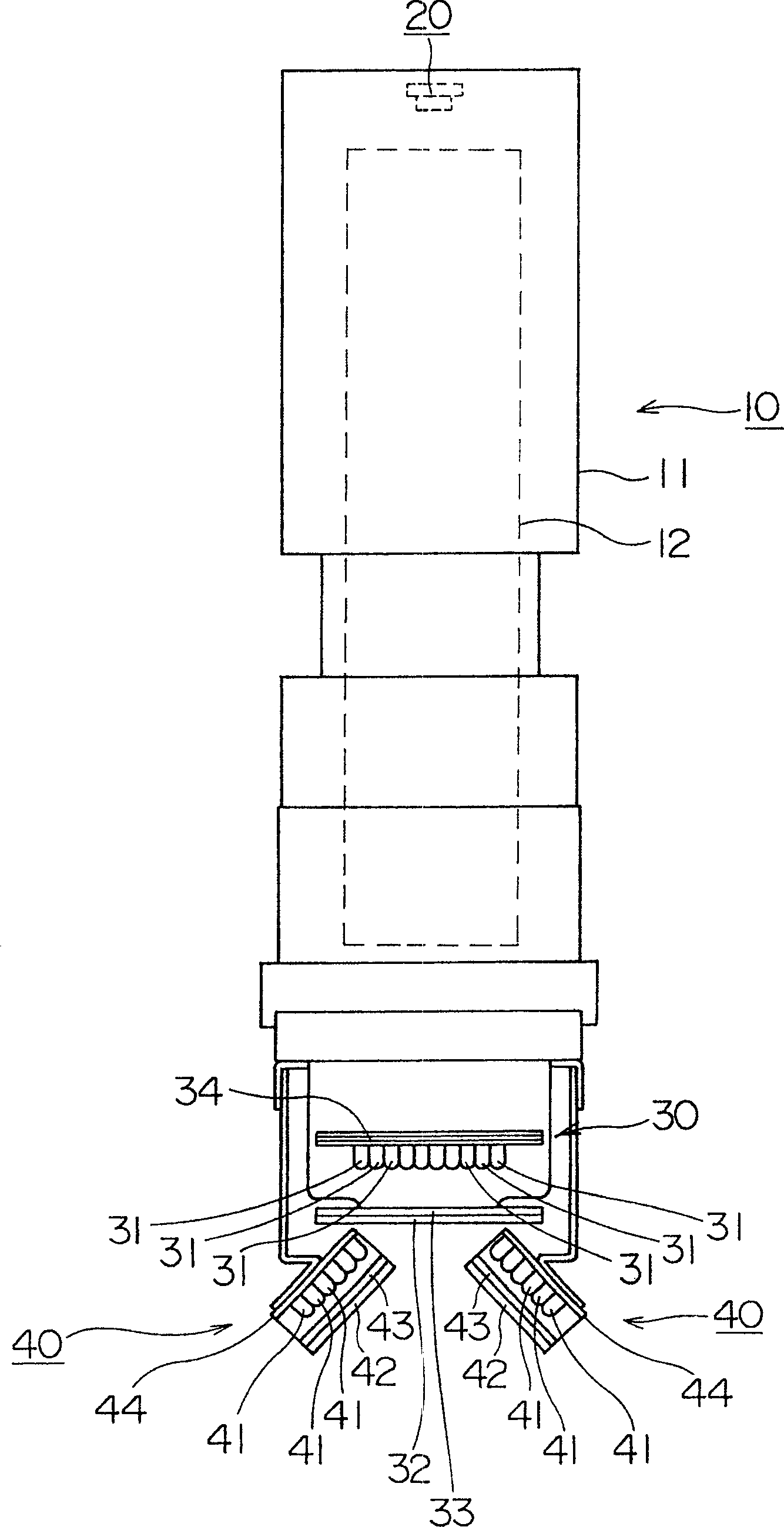

[0029] figure 1 It is a side sectional view showing the camera 10 in the substrate inspection apparatus according to the present invention. also, figure 2 From figure 1 The direction of A-A in FIG. 1 represents a cross-sectional view of the substrate inspection device according to the present invention.

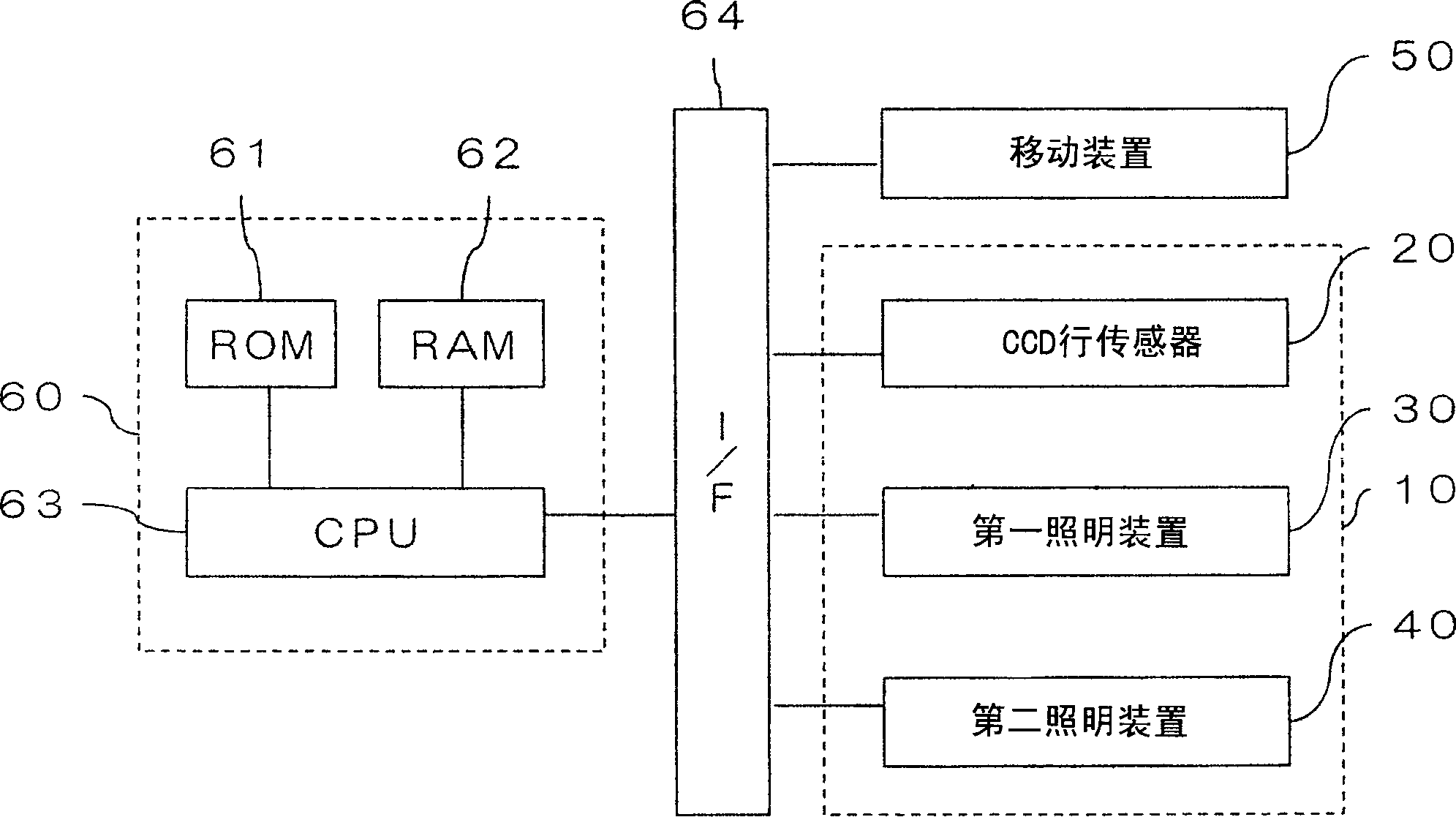

[0030] The substrate inspection device according to the present invention is a device that uses a CCD line sensor 20 in which a plurality of CCDs are arrayed to image a substrate panel, and compares the image data of the surface of the substrate that has been imaged with image data that serves as a predetermined reference. Judging whether the graphics printed on the surface of the substrate are good or not. This substrate inspection apparatus has a camera 10 for imaging the substrate and a moving device 50 for relatively moving the camera 10 relative to the substrate (re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com