Combined building with non-wainscot frame structure and construction method thereof

A frame structure, combined technology, applied in building construction, construction, etc., can solve the difficulty of increasing the amount of scaffolding, formwork and cast-in-place concrete construction management, unreasonable design, procurement, construction methods, and difficulty in adjusting use functions, etc. problems, to achieve the effect of simplifying the contract negotiation process or the bidding and bidding process, the accuracy and specification of orders and customization requirements, great flexibility and variability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

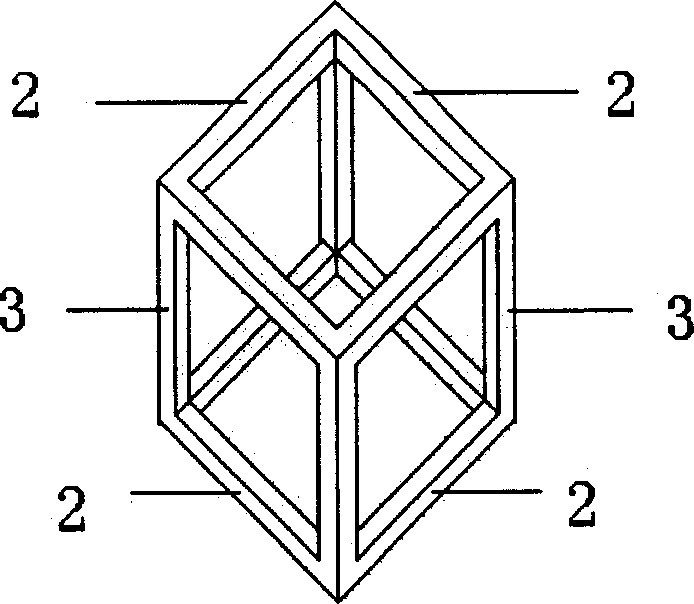

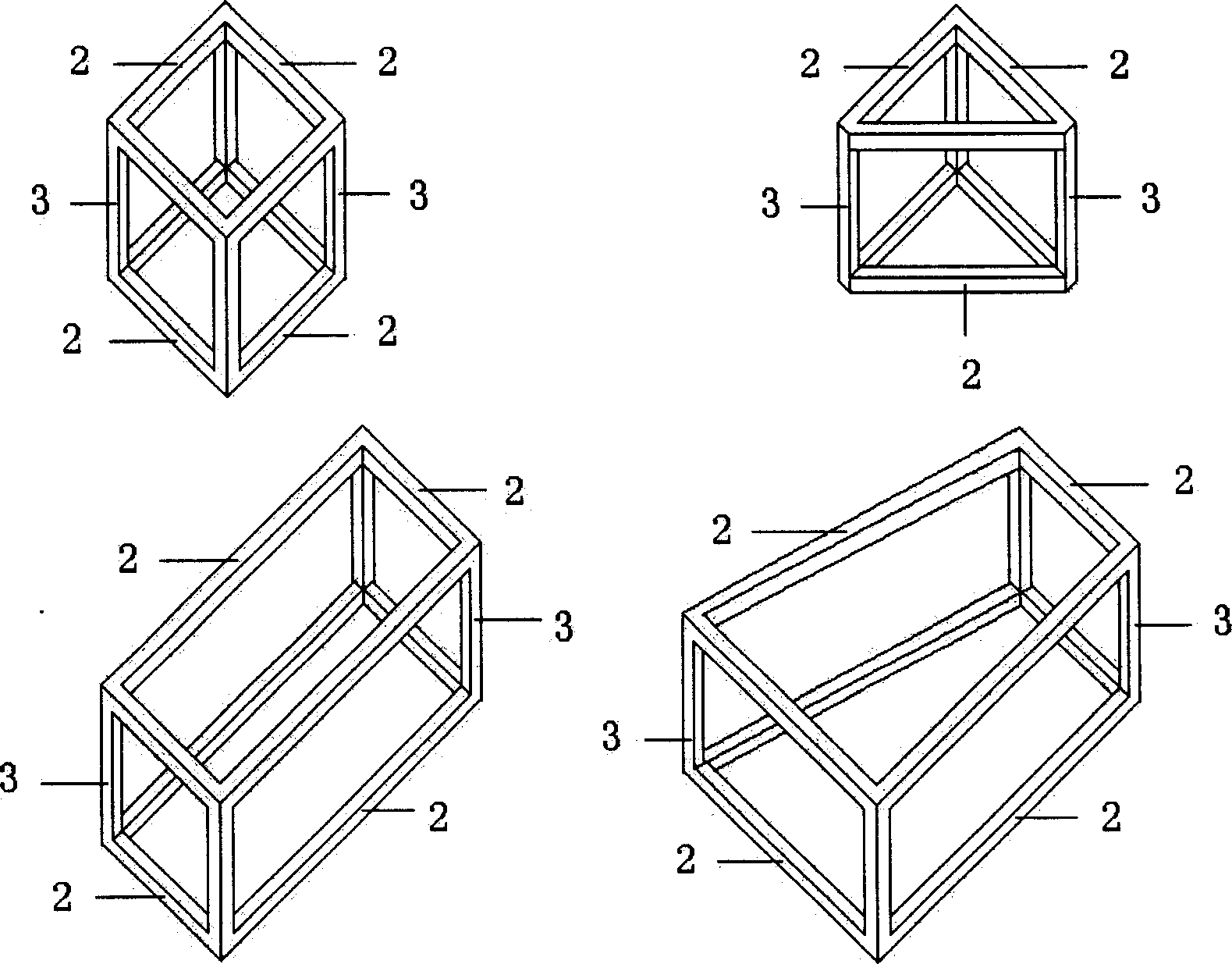

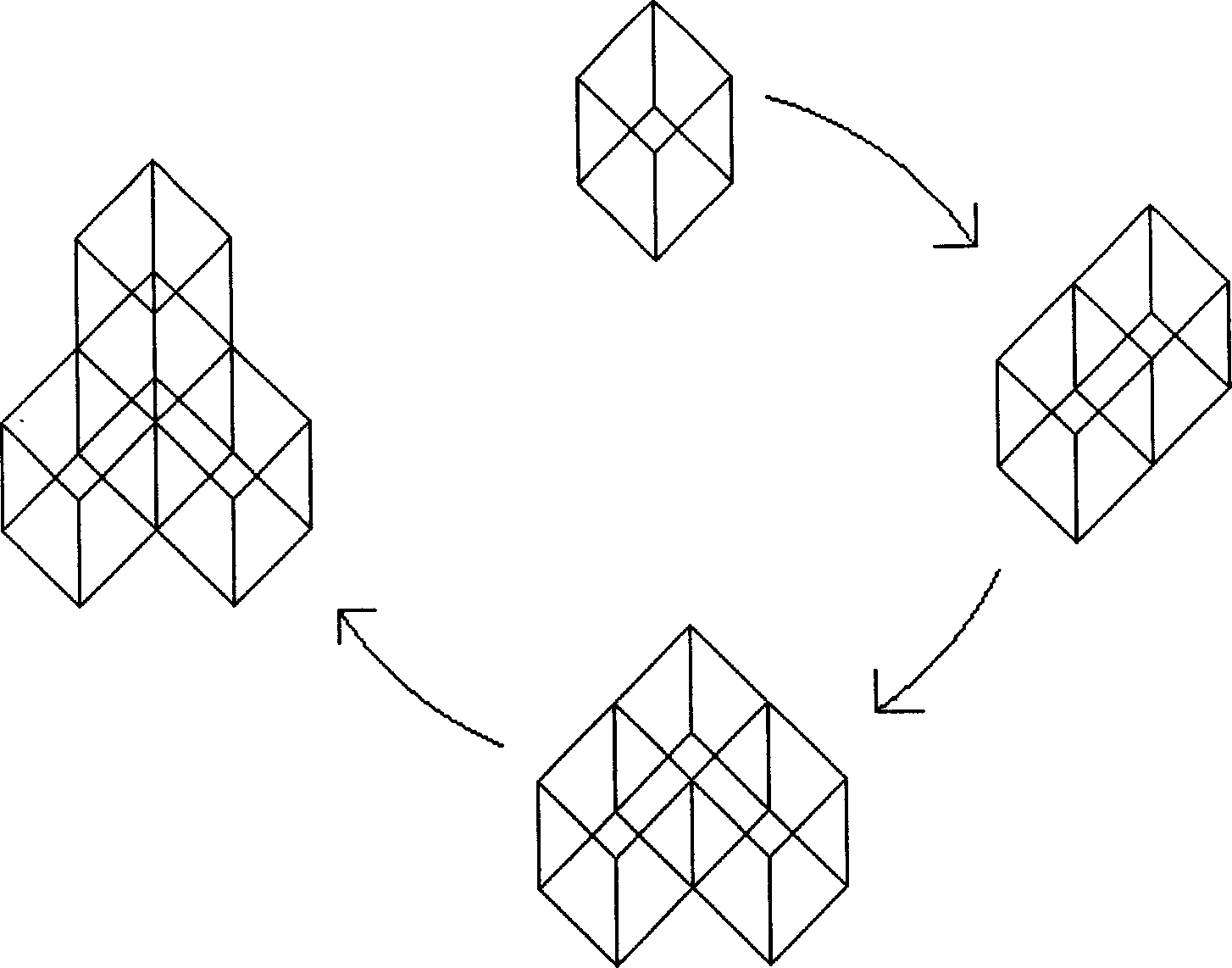

[0032] Figure 1 to Figure 11 Shown is an embodiment of the present invention, including a foundation 1, a hollow frame unit without siding and building elements 4. The foundation 1 can be a natural foundation, a strip foundation, a pile foundation or other foundations capable of supporting the weight of a building. Hollow frame units without siding have one or more such as figure 1 As shown, each hollow frame unit without siding is a cubic frame composed of four beams 2 on the upper floor, four columns 3 in the middle and four beams 2 on the lower floor. The length of the beams 2 is 2 meters to 6 meters. The height of column 3 is 2 meters to 5 meters. The shape and type of these hollow frame units without wall panels can be pre-determined, and can be cubes, cuboids, trapezoidal cubes or triangular cube frames (see figure 2 ). Made of reinforced concrete, concrete, metal, wood or any combination thereof. Such as image 3 and Figure 4 As shown, the frame units without s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com