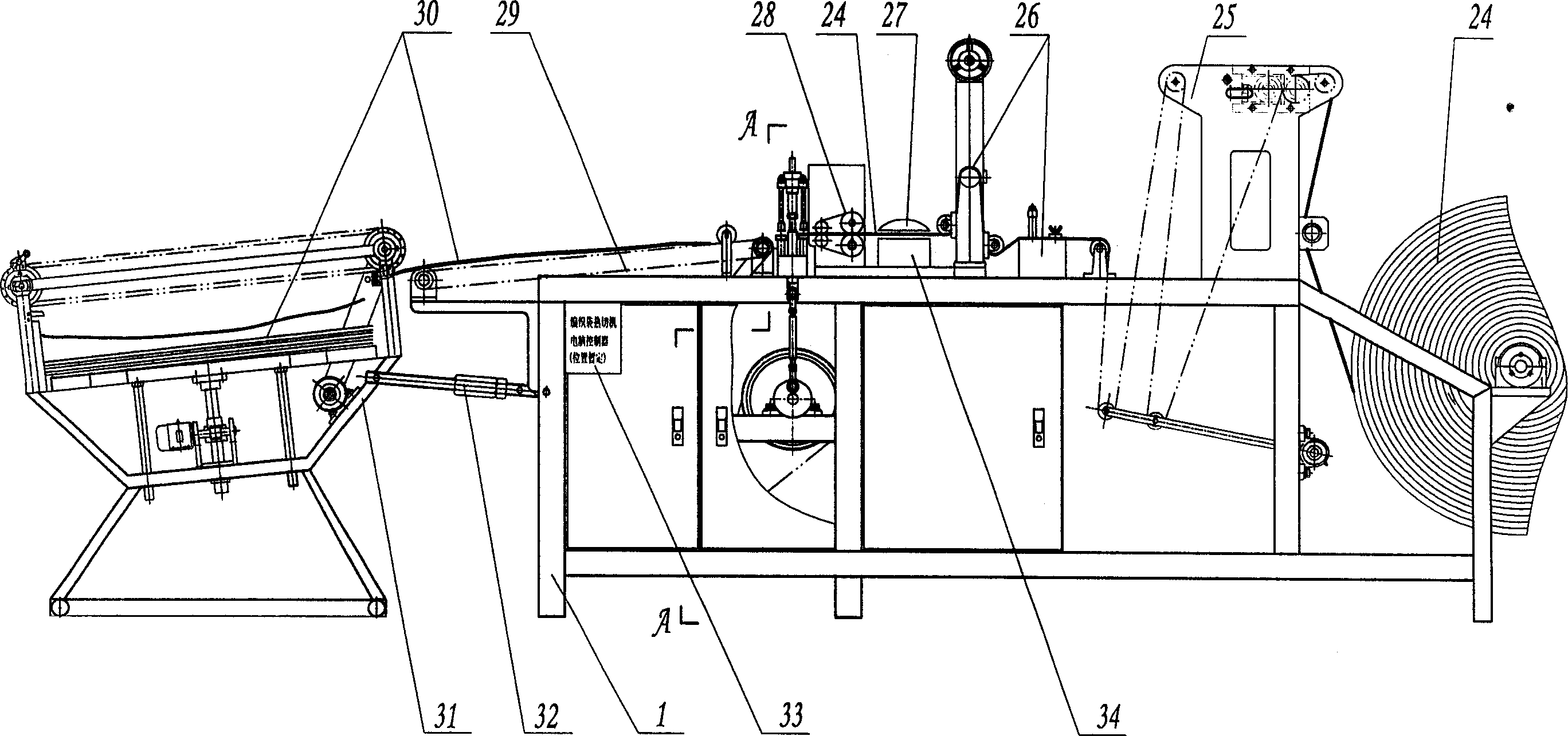

Woven bag hot-cutting machine

A technology of hot cutting machine and woven bag, which is applied in textiles and papermaking, textile material inspection, textile material cutting, etc. It can solve the problems of inaccurate length and low production efficiency when cutting into bags, and achieve large market potential and increase Quality, affordable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and embodiment:

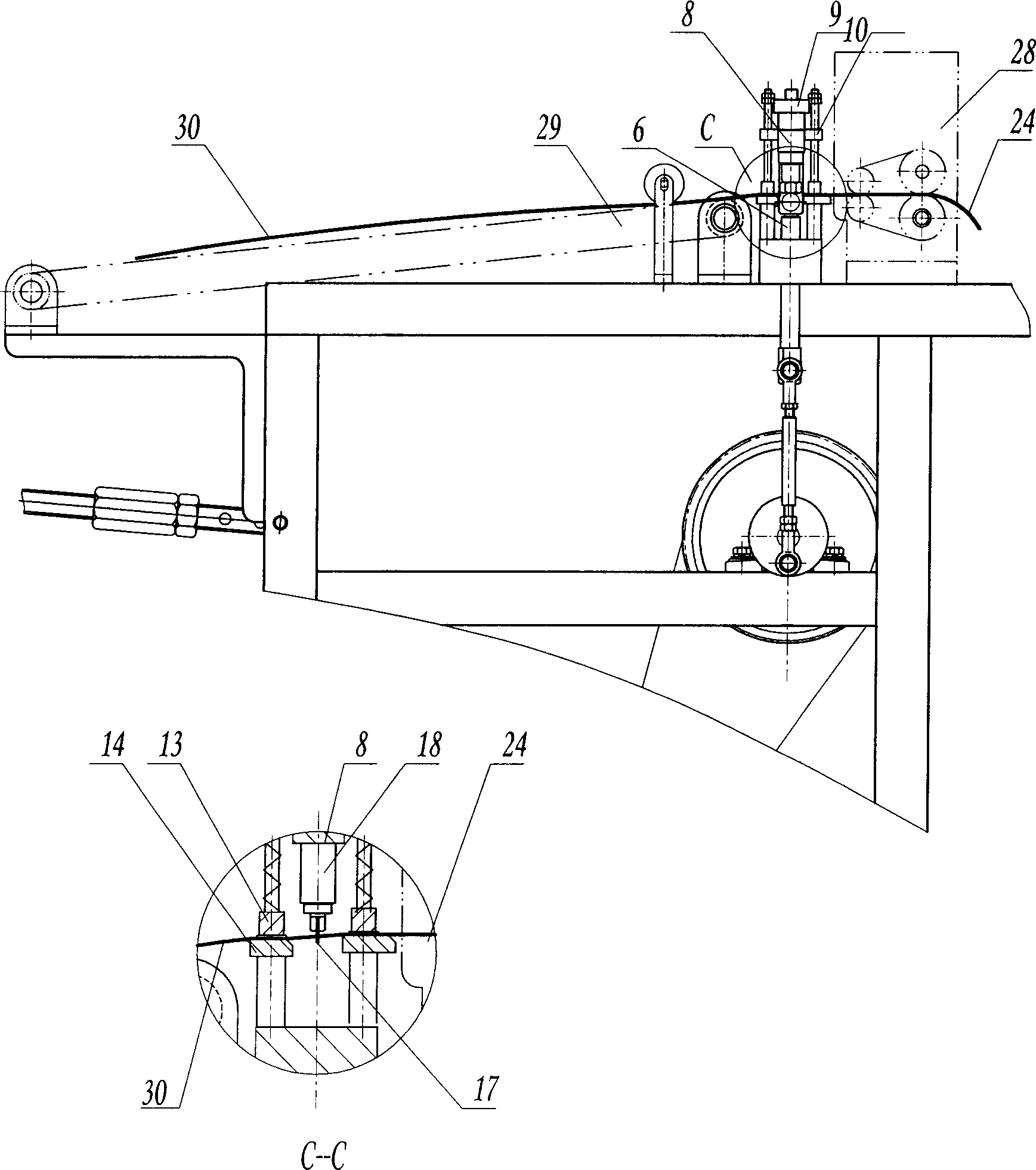

[0015] A woven bag eager cutting machine, including a feeding mechanism, an adjusting mechanism, a silicon photoelectric detection device, a feeding mechanism, a bag-pressing type cutting mechanism, a bag conveying mechanism, a chain-belt ring-type bag collecting mechanism, the bag-pressing type cutting mechanism The left and right ends of the drive shaft 2 on the mechanism are respectively connected to the eccentric wheel 3, and the end faces of the eccentric wheel are eccentrically connected to the left and right connecting rods 4 symmetrically, and the left and right connecting rods are connected to the sliding rod 6. 5 is slidingly matched with the middle section of the slide bar 6; the horizontal seat 16 corresponds to the position of the upper knife rest 8, and the knife rest 8 reciprocates up and down above the horizontal seat 16. The cutting depth of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com