Method of no conglutination for packing blocky heat-molten contact adhesive

A technology of hot-melt pressure-sensitive adhesive and packaging method, which is applied to the non-adhesive packaging of block hot-melt pressure-sensitive adhesive in a viscous state, in the field of normal temperature, and can solve the problems of poor compatibility between film and hot-melt pressure-sensitive adhesive, sizing pipeline and Nozzle blockage, inconvenient production and use, etc., to achieve performance assurance, low packaging cost, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

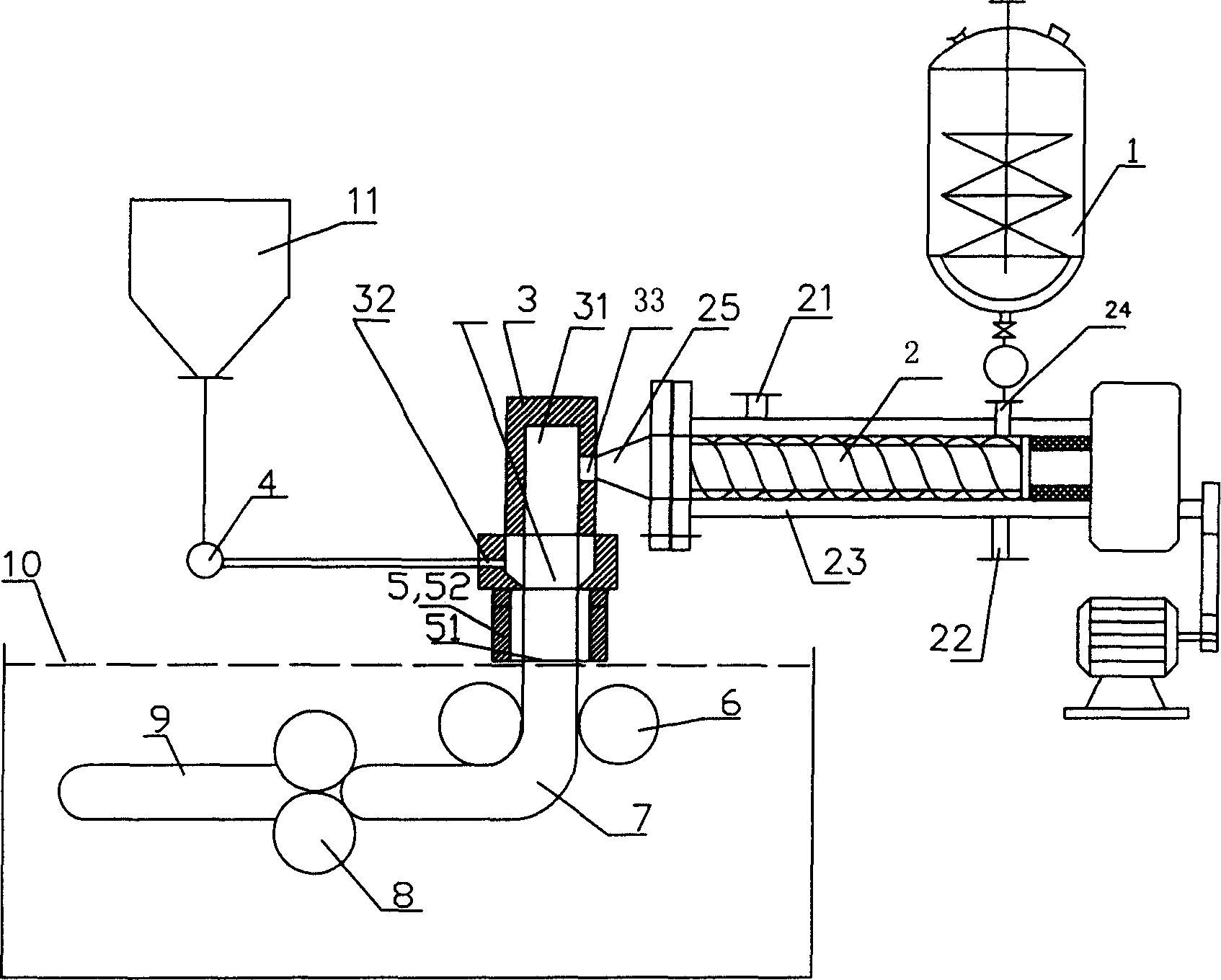

[0016] The non-adhesive packaging method of block hot-melt pressure-sensitive adhesive has the following process steps:

[0017] 1) Prepare a liquid hot-melt pressure-sensitive adhesive in the mixing kettle 1, and prepare an anti-sticking coating in the coating kettle 11. Anti-stick coatings are paraffin wax, polyethylene wax, synthetic wax, modified polyethylene wax, polyamide wax, stearamide wax, ethylene-vinyl acetate copolymer, polyethylene, thermoplastic rubber, ethylene-methyl acrylate copolymer , ethylene-butyl acrylate copolymer, and one or more mixtures of high softening point tackifying resin raw materials. The thickness of the release coating is calculated as 0.05%-2% by weight percentage of the packaged hot-melt pressure-sensitive adhesive.

[0018] 2) Send the melted hot-melt pressure-sensitive adhesive from the mixing kettle 1 into the screw extruder 2 with a temperature control device 23 . And the release coating is sent into the mold cavity 31 of the release ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com