Operator cab for construction machine

一种工程机械、驾驶室的技术,应用在驾驶室领域,能够解决制造成本增加、开闭感觉差、门结构复杂等问题,达到减轻重量、开闭感觉好、门结构简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

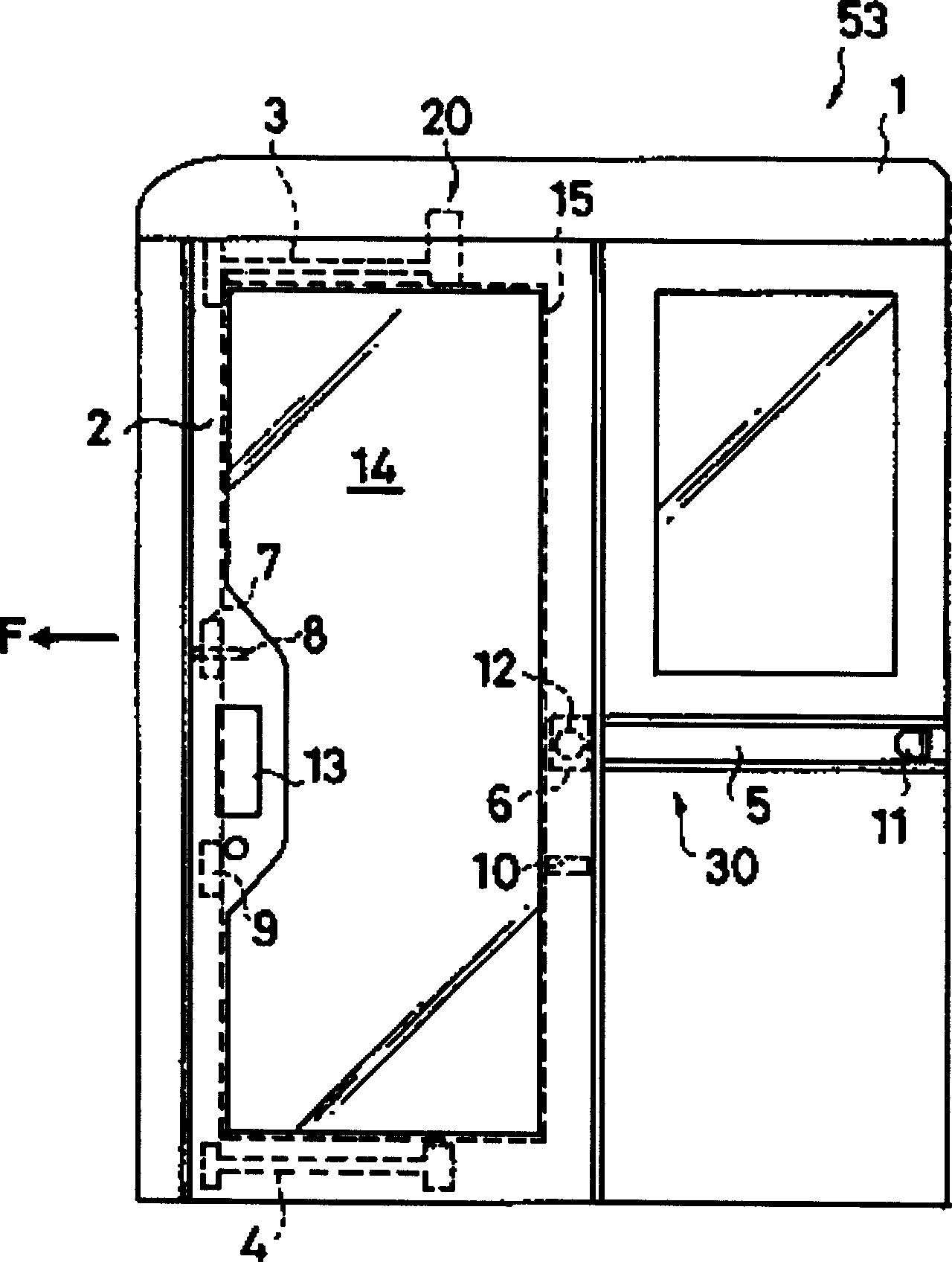

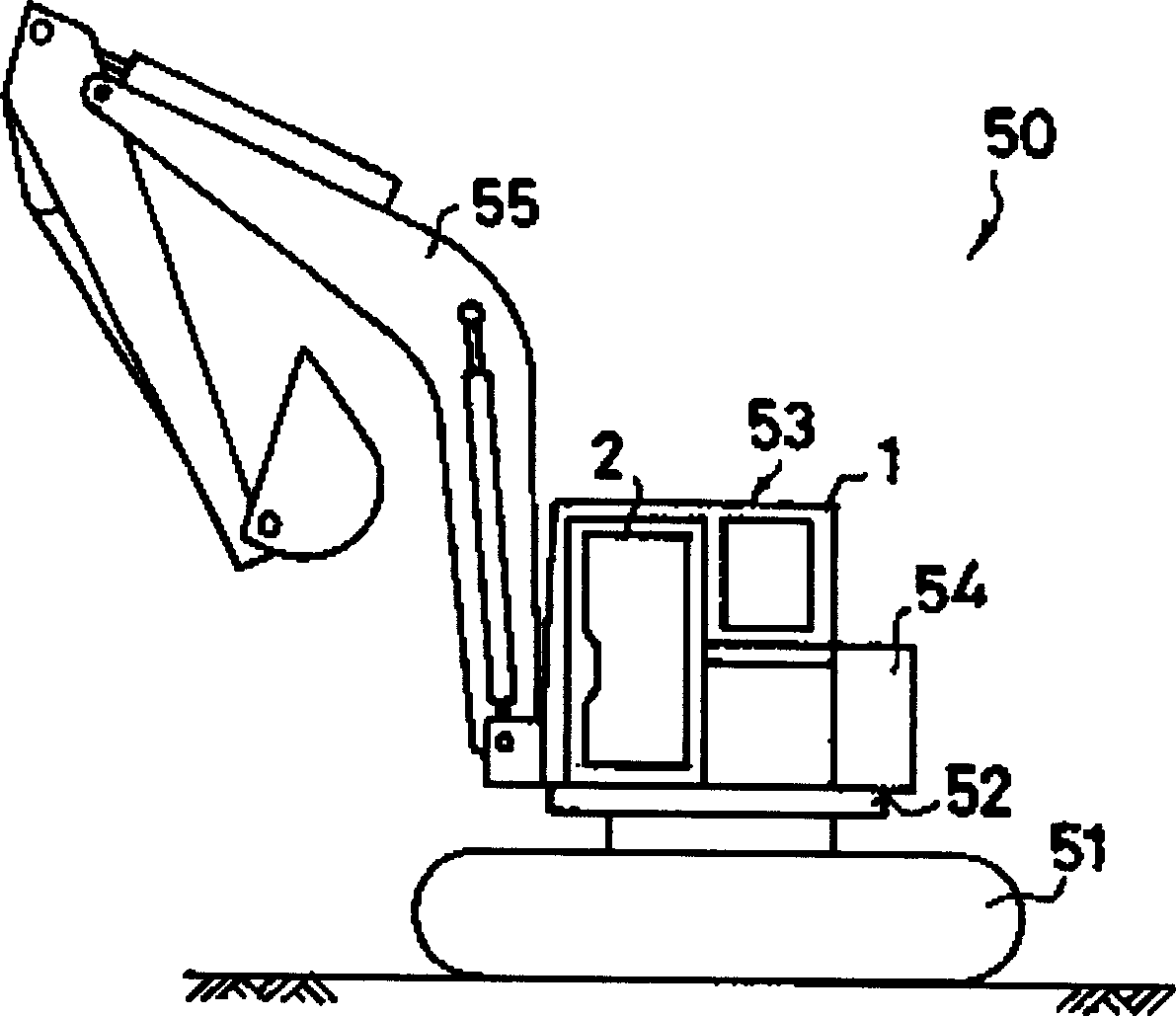

[0032] use figure 1 ~FIG. 8 demonstrates the first embodiment of the structure of the door 2 with which this cab 53 is assembled. In addition, in the following description, the closing direction of door 2 ( figure 1 The direction of the middle arrow F) is described as the front. door 2 as figure 1 As shown, the front part is assembled on the cab box body 1 by the link mechanism 20, and the rear part is assembled on the cab box body 1 by the sliding mechanism 30, so as to be formed on the cab box body 1 which can be opened and closed. And the entrance and exit 15 communicated with the cab space 1a are opened and closed. The link mechanism 20 is assembled to the upper link member 3 and the lower link at the upper and lower parts of the door 2 with one end pivotally connected to the cab box 1 in a swingable manner and the other end pivotally connected to the door 2 in a swingable manner. Composed of 4 parts. The sliding mechanism 30 is then composed of a sliding guide rai...

no. 2 example

[0050] In the first embodiment, the case where the front part of the door 2 is supported by the link mechanism 20 and the rear part is supported by the sliding mechanism 30 is described, but the front and rear parts may also be supported by the link mechanism or the sliding mechanism. Describe its composition. In addition, in the following description, the same components as those of the first embodiment are given the same reference numerals, and their descriptions are omitted.

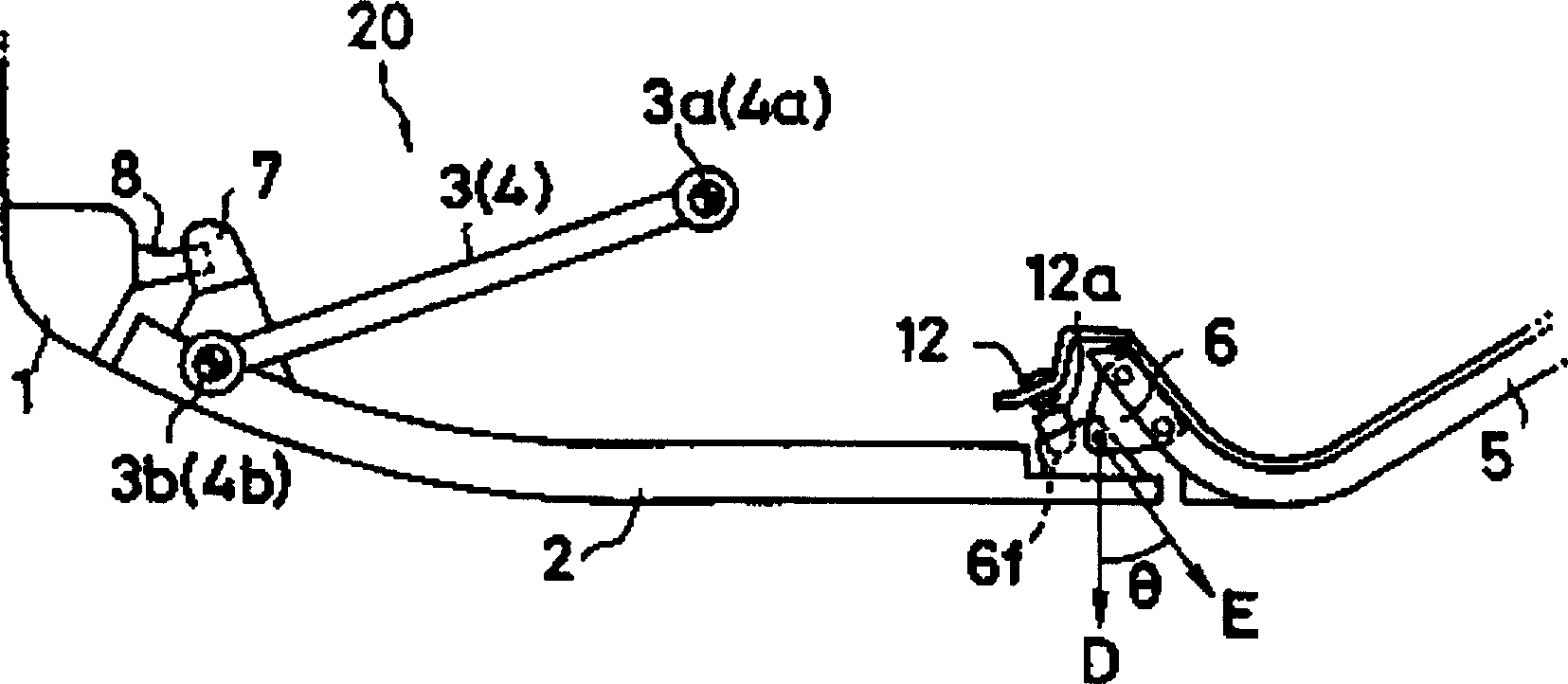

[0051] First, use Figure 1 to Figure 13 A case where the front and rear parts of the door 2 are supported by the link mechanism 120 as the second embodiment will be described. In the second embodiment, the link mechanism 120 is composed of a front link member 103 and a rear link member 104 assembled side by side, one end (fixed end 103a, 104a) is connected to the upper part of the cab box body 1 in a swingable manner. The other end (movable end 103b, 104b) is pivotally connected to the front and re...

no. 3 example

[0057] use below Figure 14 ~ Figure 16 A case where only the front and rear parts of the door 2 are supported by the slide mechanisms 30, 230, 240 will be described as a third embodiment. In this third embodiment, the top of the front part of the door 2 is supported by an upper sliding mechanism 230, the bottom of the front part is supported by a lower sliding mechanism 240, and the substantially central part in the up-down direction of the rear part is supported by the same sliding mechanism 30 as in the first embodiment. support.

[0058] The upper sliding mechanism 230 is composed of an upper sliding guide rail 203 assembled on the cab box body 1 along the top edge of the entrance and exit formed on the cab box body 1 and an upper sliding member 303 that moves in a sliding manner along the upper sliding guide rail 203 , The lower sliding mechanism 240 is composed of a lower sliding guide rail 204 assembled on the cab box body 1 along the bottom edge of the entrance and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com