Process for producing electric smelting zirconium corundum 33#, 36#, 41# products by secondary casting

A zirconium corundum and product technology, applied in the field of silicate, can solve the problems such as the inability to reduce the production cost to a minimum, the inability to remove a large amount of impurities in waste, and the inability to achieve product quality, so as to solve the problem of quality and production cost, and production cost reduction , the effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

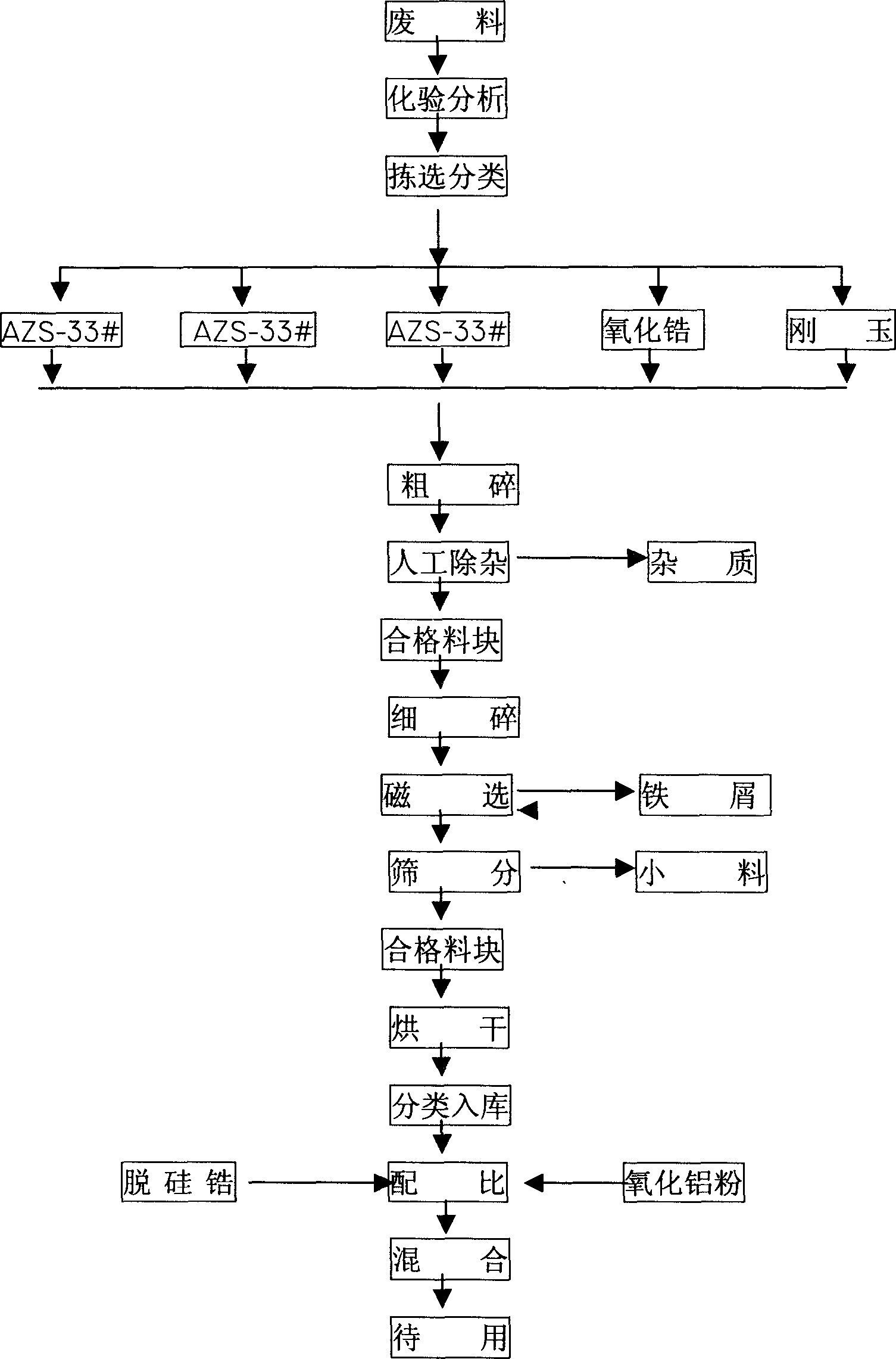

[0023] 1. Special treatment of waste

[0024] The fused cast zirconia corundum waste used in the glass industry; the fused cast and sintered zirconia waste; the fused cast and sintered corundum waste used in the glass industry are analyzed and tested. Obvious impurities such as glass and iron in the container should be classified and stored;

[0025] Coarsely crush and finely crush similar waste materials, remove iron by magnetic separation, classify and sieve, so that the particle size is controlled within the range of 0.1---50mm, dry the treated waste materials, the moisture content is ≤0.5%, and store them in different levels silo;

[0026] 2. Ingredients

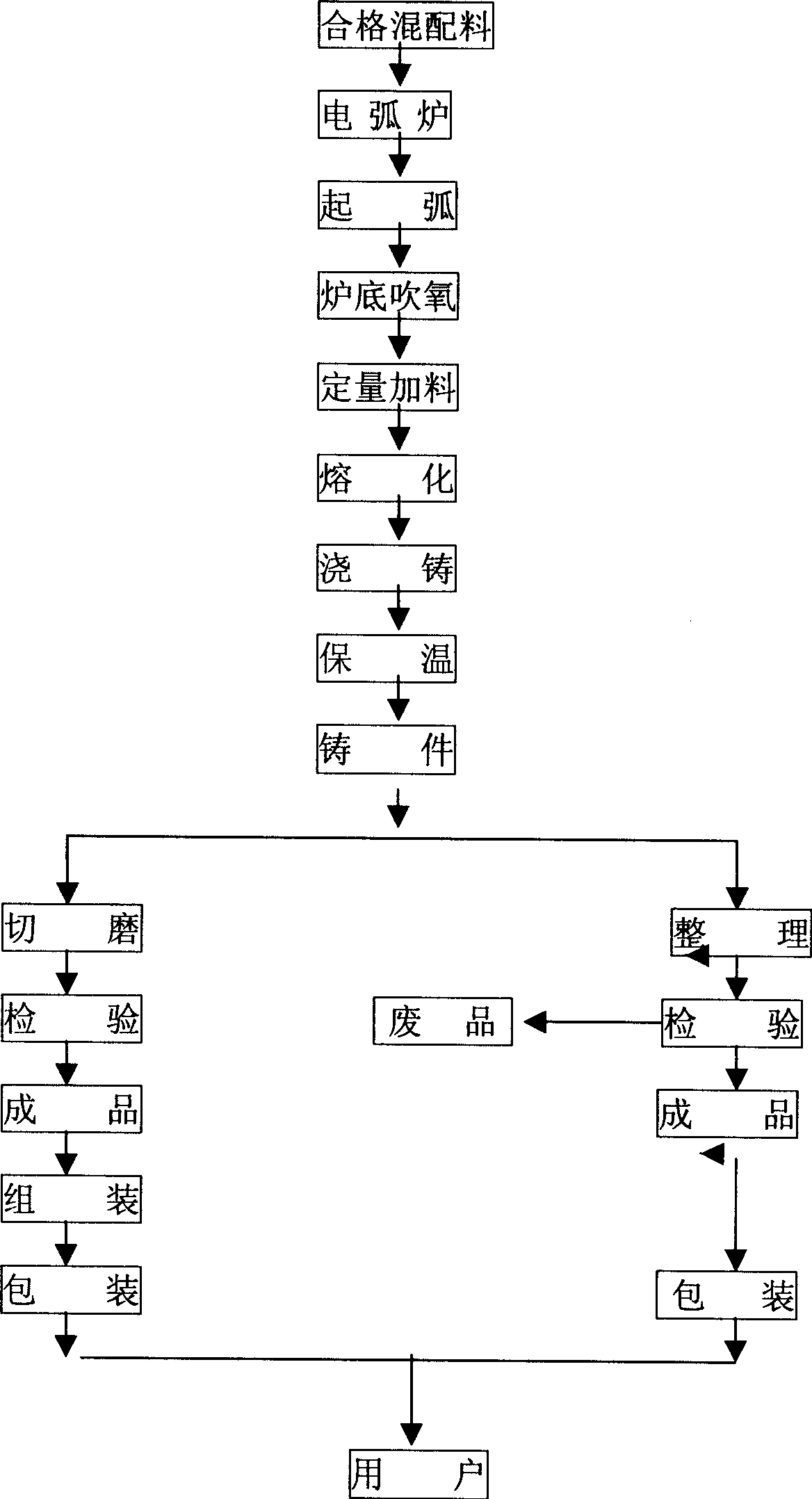

[0027] According to the results of chemical composition analysis, combined with the requirements of physical and chemical performance indicators such as zirconia and alumina content of the products to be produced, the waste of fused and cast zirconia corundum is used as the main raw material, and the ratio method of ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com