Servo driver for DC electric machine

A technology of servo drive and DC motor, which is applied in the field of servo drive, can solve the problems of large overshoot and long adjustment time, and achieve the effects of reducing components, saving electric energy and improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

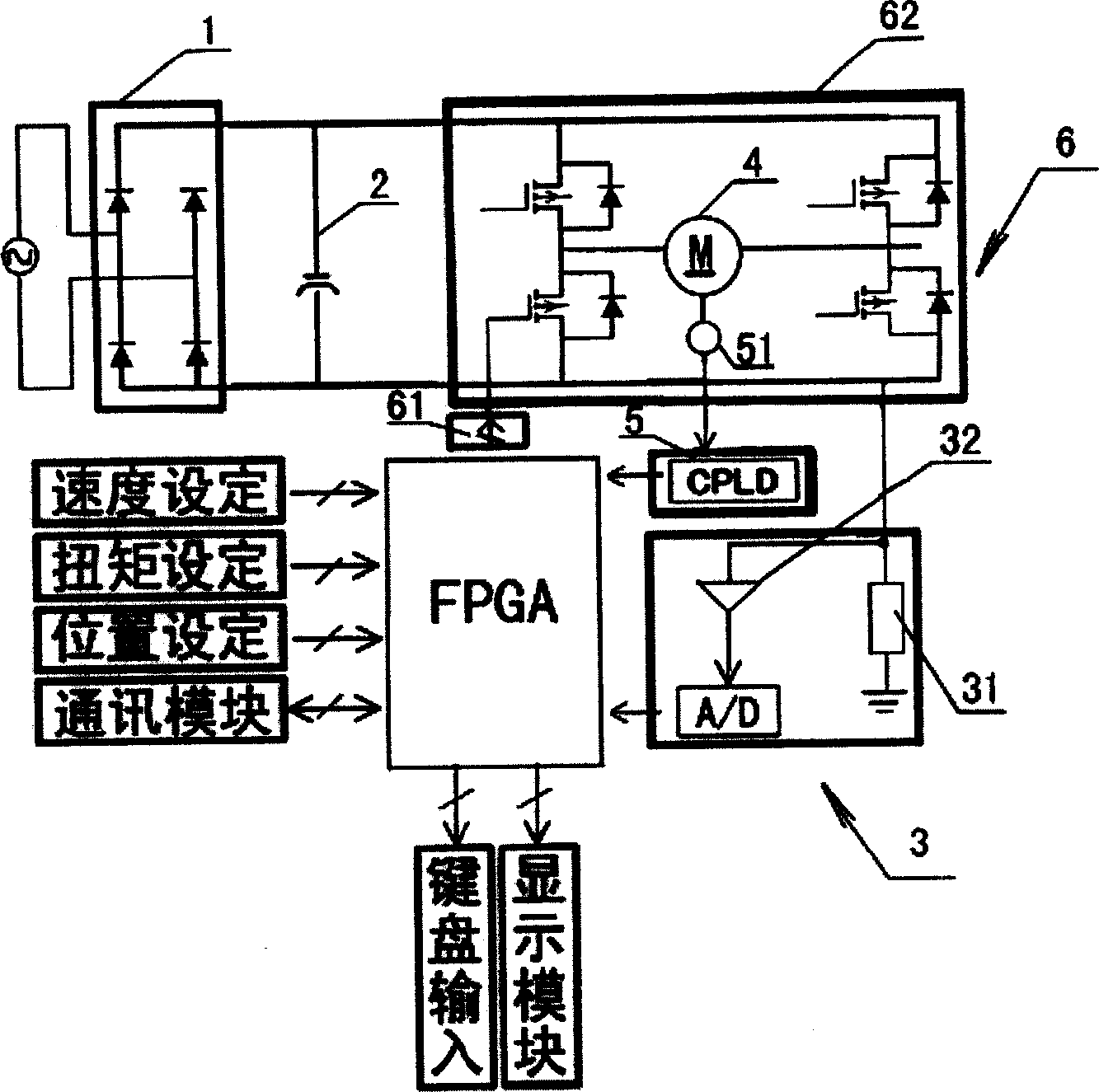

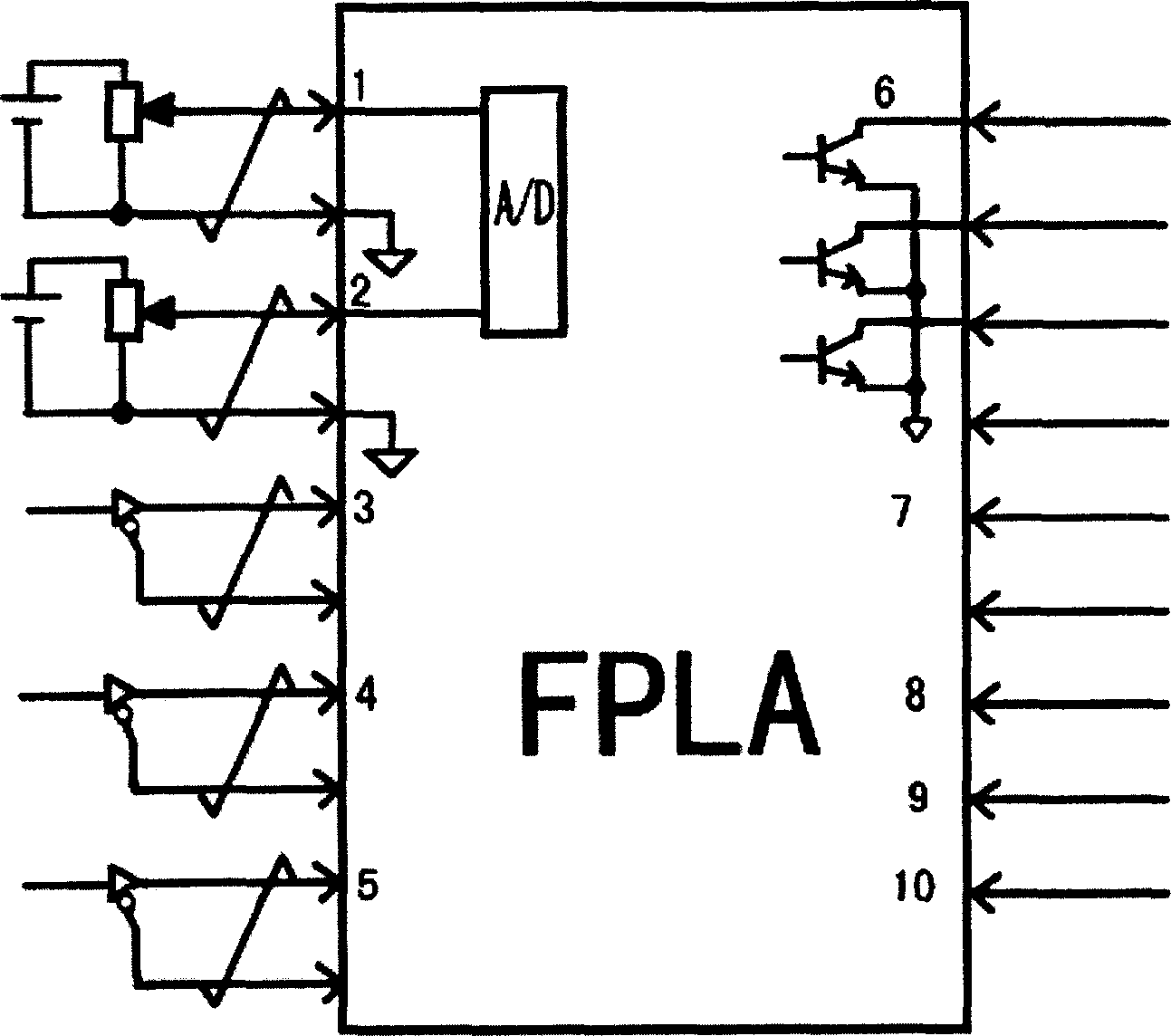

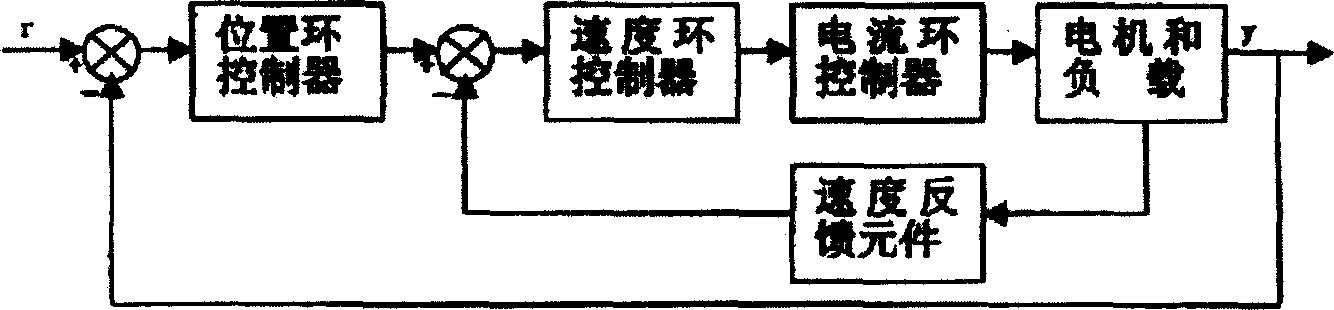

[0018] see figure 1 and figure 2 , these two figures show the control principle block diagram of an embodiment of the DC motor servo driver proposed by the present invention. The servo driver in this embodiment includes a rectification module 1, a filter capacitor 2, a feedback unit and a main control unit FPGA. The feedback unit includes a current feedback component 3 and a speed feedback component 5 .

[0019] The current feedback component 3 is composed of a sampling resistor 31 connected to the armature current of the motor 4 and an amplifier 32 that amplifies the current signal taken out of the sampling resistor 31, and then converts the amplified current analog signal into a digital signal. Device A / D constitutes. The current feedback component 3 may also be composed of a current sensor with its own amplification and analog-to-digital conversion functions. The speed feedback assembly 5 includes an encoder 51 installed at the output end of the motor and a data prepro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com