Continuously producing method for proplonic acid by oxidizing propionic aldehyde

A technology for oxidizing propionic acid and production methods, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems that are not suitable for large-scale industrial production, high requirements for equipment and pipeline materials, and poor product quality control Stability and other issues, to achieve the effect of short reaction time, good product quality and stable properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

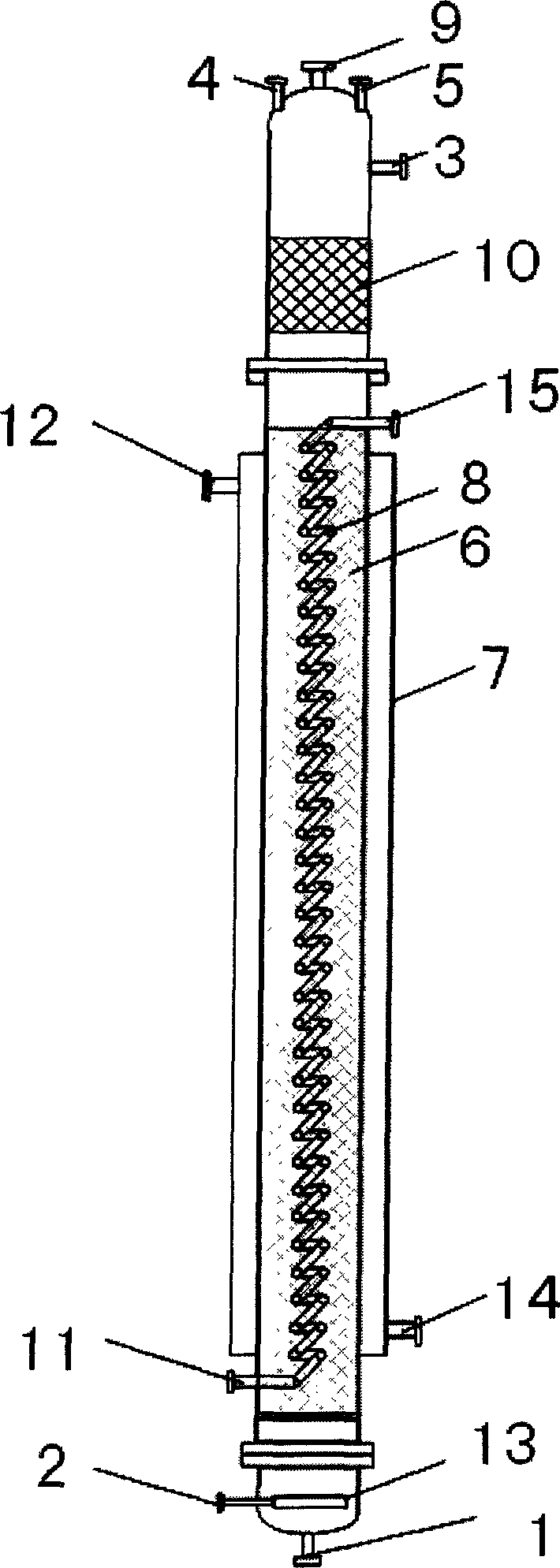

[0034] Example 1, firstly the raw material propionaldehyde is mixed with the catalyst, secondly the mixed propionaldehyde and catalyst and air or oxygen are sent to the bottom of the reaction tower, and then the reaction is carried out in the reaction tower at a reaction temperature of 80°C or 90°C or 100°C, The propionic acid that reaction generates gradually obtains primary crude propionic acid from the overflow of reaction tower; Wherein:

[0035] The catalyst includes a main catalyst and a co-catalyst, the main catalyst is propionate or acetate or naphthenate, the co-catalyst is phosphoric acid, and the weight ratio of propionaldehyde to the main catalyst is 1000 to 0.5 or 1000 to 0.8 or 1000 to 1.0 Or 1000 to 1.5 or 1000 to 2.0 or 1000 to 2.5 or 1000 to 3.0, the weight ratio of propionaldehyde to cocatalyst is 1000 to 0.5 or 1000 to 0.8 or 1000 to 1.2 or 1000 to 1.8 or 1000 to 2.5 or 1000 to 3.2 Or 1000 to 4.0 or 1000 to 4.8 or 1000 to 5.2 or 1000 to 6.0;

[0036] The mo...

Embodiment 2

[0040] Embodiment 2 is different from Embodiment 1 in that: in Embodiment 2, the crude propionic acid that overflows is passed through a low-pressure separation tank to obtain secondary crude propionic acid.

Embodiment 3

[0041] Example 3, the difference from Example 1 and Example 2 is that: in Example 3, the primary crude propionic acid or secondary crude propionic acid in the above-mentioned embodiment can be subjected to normal pressure at 138°C or Perform rectification at 140°C or 142°C to obtain fine propionic acid.

[0042] Among the above main catalysts:

[0043] The propionate may preferably be cobalt propionate or manganese propionate, or cobalt propionate and manganese propionate.

[0044] The acetate may preferably be cobalt acetate or manganese acetate, or cobalt acetate and manganese acetate.

[0045] The naphthenate may preferably be cobalt naphthenate or manganese naphthenate, or cobalt naphthenate and manganese naphthenate.

[0046] In the above-mentioned embodiment, in order to further improve the effects such as the safety of the continuous production method of propionic acid prepared by propionaldehyde oxidation of the present invention, further optimization or / and improvem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com