Catalyst and method for decomposition of perfluoro-compound in waste gas

A technology of perfluorinated compounds and catalysts, which is applied in the fields of perfluorocarbon/hydrofluorocarbon capture, chemical instruments and methods, physical/chemical process catalysts, etc., which can solve the problem that catalyst life cannot be guaranteed by complex preparation methods of catalysts, etc. problem, to achieve high catalytic activity and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example I

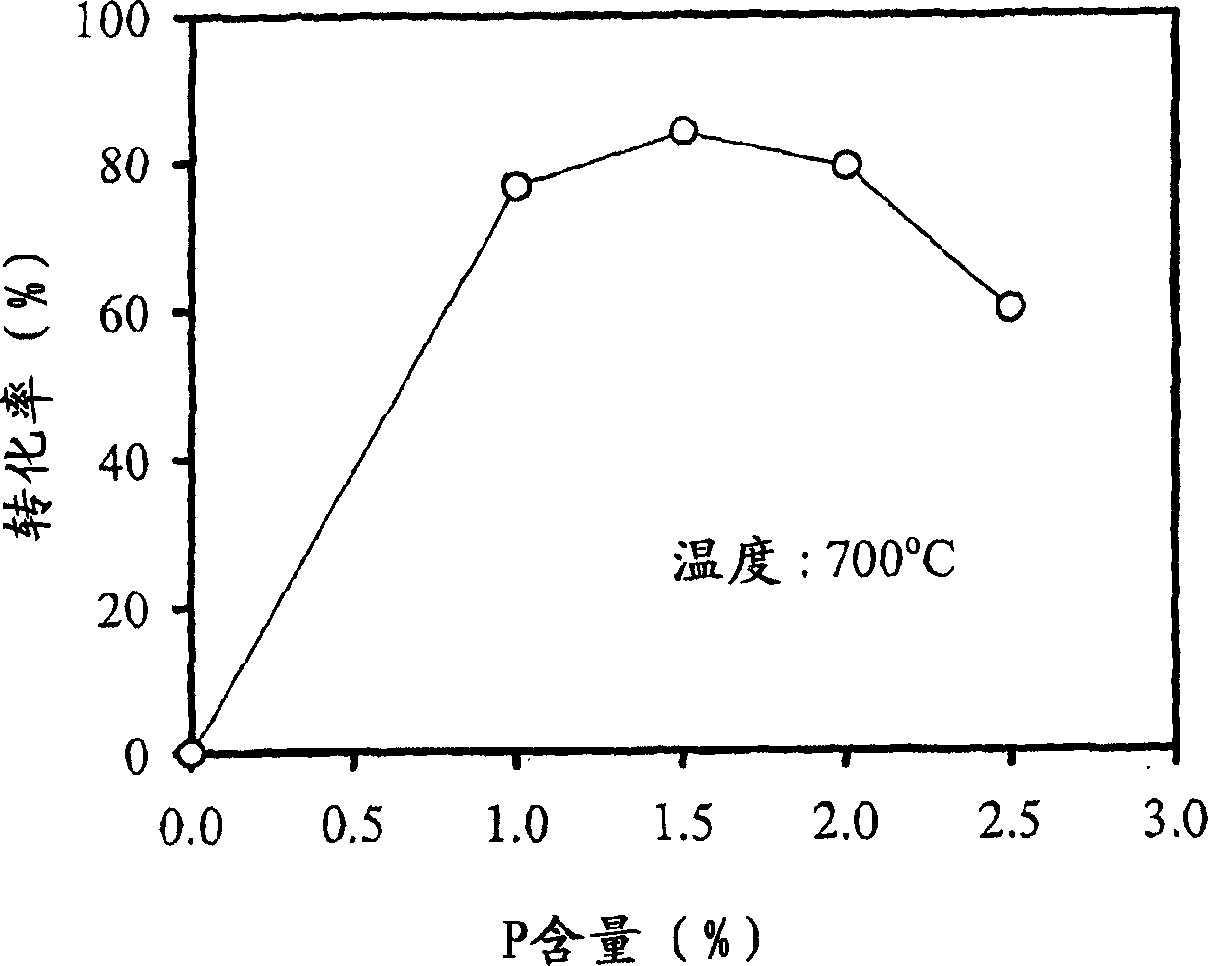

[0056] In order to prepare an alumina catalyst loaded with 2.5 mol% P (Al / P=39), 2.7 g (NH 3 ) 2 HPO 4 impregnated into 40g of alumina (Al 2 o 3 ) powder, then dried in an oven at 100°C for 10 hours, and calcined in a muffle furnace at 750°C for 10 hours.

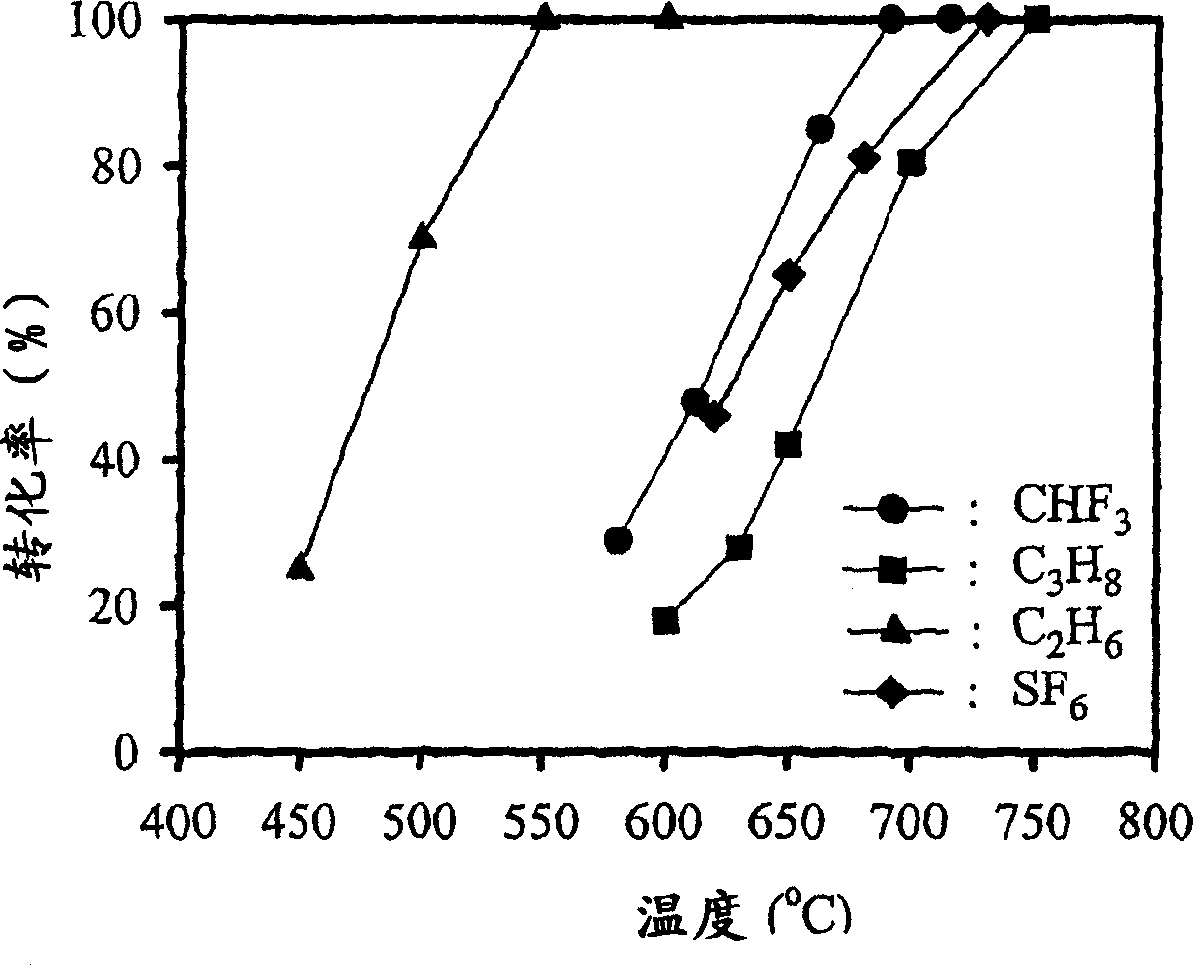

[0057] Fill 5g of the prepared catalyst into a 3 / 4" Inconel tube, and then carry out the PFC decomposition reaction while passing 1.01ml / min CF 4 , 2.87ml / min O 2 and 89.4ml / min He gas, which corresponds to 1.08vol% CF excluding water at room temperature 4 and 1500h -1 airspeed. Using a syringe pump, introduce 0.04 ml / min of distilled water along with the gas mixture. Calculate CF according to the following formula 1 4 Conversion rate. Such as figure 1 As shown, above 690°C, CF 4 Decomposes to CO with 100% selectivity 2 .

[0058] Formula 1

[0059] CF 4 Conversion = [1-(reactor outlet CF 4 Concentration / reactor inlet CF 4 Concentration)]×100

[0060] Formula 2

[0061] CO 2 Selectivity = (CO produced ...

example II

[0063] After loading the catalyst that 5g example 1 makes, carry out NF under the same reaction condition with example 1 3 decomposition reaction. instead of CF 4 , put 1.01ml / min NF 3 , 2.87ml / min O 2 And 89.4ml / min He gas was fed into the reactor together with 0.04ml / min distilled water. Such as figure 1 shown, above 400°C, 100% NF 3 Decomposed. After reacting at 500° C. for 10 hours, the catalyst was subjected to elemental analysis using an energy dispersive x-ray analyzer (EDAX). It was found that the F component did not accumulate in the catalyst even after the reaction.

example III

[0065] After loading the catalyzer that 5g example 1 makes, carry out C under the identical reaction condition with example II 4 f 8 decomposition reaction. replace NF 3 , put 1.08ml / min C 4 f 8 , 2.87ml / min O 2 And 89.4ml / min He gas was fed into the reactor together with 0.04ml / min distilled water. It was found that above 690°C 100% C 4 f 8 is decomposed into CO 2 (see figure 1 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com